Patents

Literature

46results about How to "Improves anti-foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

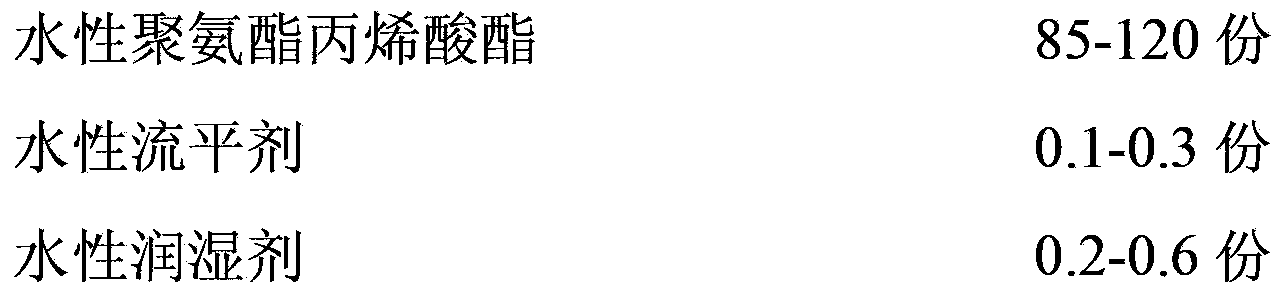

Water-based ultraviolet-thermal dual-curing coating and preparation method thereof

ActiveCN103409060AImprove water resistanceGood anti-foamPolyurea/polyurethane coatingsWater basedUrethane acrylate

The invention provides a water-based ultraviolet-thermal dual-curing coating and a preparation method thereof, belongs to the technical field of water-based coatings and solves the problem that a conventional water-based ultraviolet-thermal dual-curing coating has poor waterproof and anti-foaming properties. The coating provided by the invention comprises 85-120 parts of water-based urethane acrylate, 0.1-0.3 part of water-based flatting agent, 0.2-0.6 part of water-based wetting agent, 1.2-2.6 parts of photoinitiator, 8-12 parts of water-based cosolvent and 4.5-8 parts of water-based curing agent. The water-based urethane acrylate is nonionic water-based urethane acrylate modified by silicone. The invention further provides the preparation method of the water-based ultraviolet-thermal dual-curing coating. After being soaked in indoor-temperature water for 24 hours, the water-based ultraviolet-thermal dual-curing coating doesn't foam, wrinkle or flake off, which proves that the water-based ultraviolet-thermal dual-curing coating has excellent waterproof and anti-foaming properties.

Owner:CHANGCHUN SANHUA IND

Complexing agent for preparing engine oil

The invention provides a complexing agent for preparing an engine oil. The complexing agent for preparing the engine oil is characterized by comprising a base oil, a dispersing agent, a cleansing agent, an anti-wear agent, an antioxidant, a viscosity index improver, a pour point depressant, an anti-foaming agent, a demulsifying agent and titanium oxide. The dispersing agent is polyisobutene-bis-succinimide; the cleansing agent is alkyl sulfide calcium powder; the anti-wear agent is phosphate; the antioxidant is sulfenyl-benzimidazole; the viscosity index improver is styrene-diene copolymer; the pour point depressant is polyalkyl methacrylate; the anti-foaming agent is polydimethylsiloxane; and the demulsifying agent is polyoxyalkylene polyamine. The components comprise 9-11% of dispersing agent, 11-12% of cleansing agent, 5-6% of anti-wear agent, 12-13% of antioxidant, 4-5% of viscosity index improver, 4-5% of pour point depressant, 8-9% of anti-foaming agent, 12-13% of demulsifying agent, 2-3% of titanium oxide and the balance of base oil in percentage by weight. The complexing agent for preparing the engine oil, provided by the invention, has the advantages of simple manufacturing method, economic efficiency, practicability, low price of the manufactured product, high quality, capability of prolonging the life cycle of the lubricating oil, improving the anti-wear and extreme pressure resistant effects of the lubricating oil and enhancing multiple effects of oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil, long-term retention of cleansing effect of the lubricating oil and capability of comprehensively enhancing the comprehensive effect of the engine lubricating oil.

Owner:TIANJIN GONGBO SCI TECH DEV

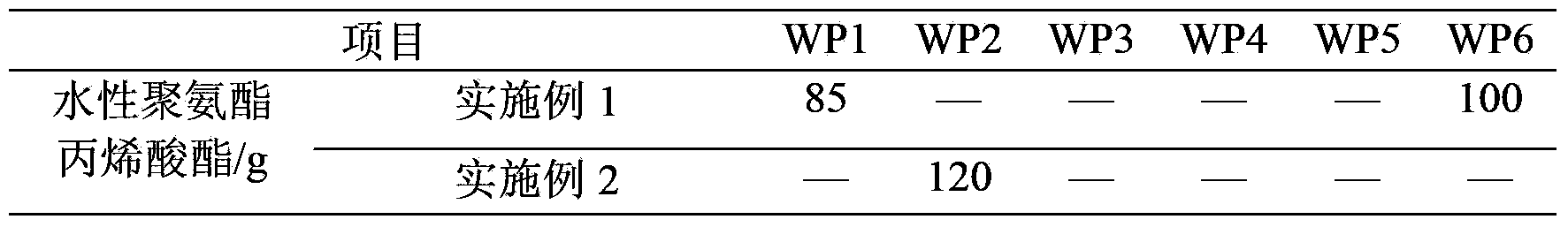

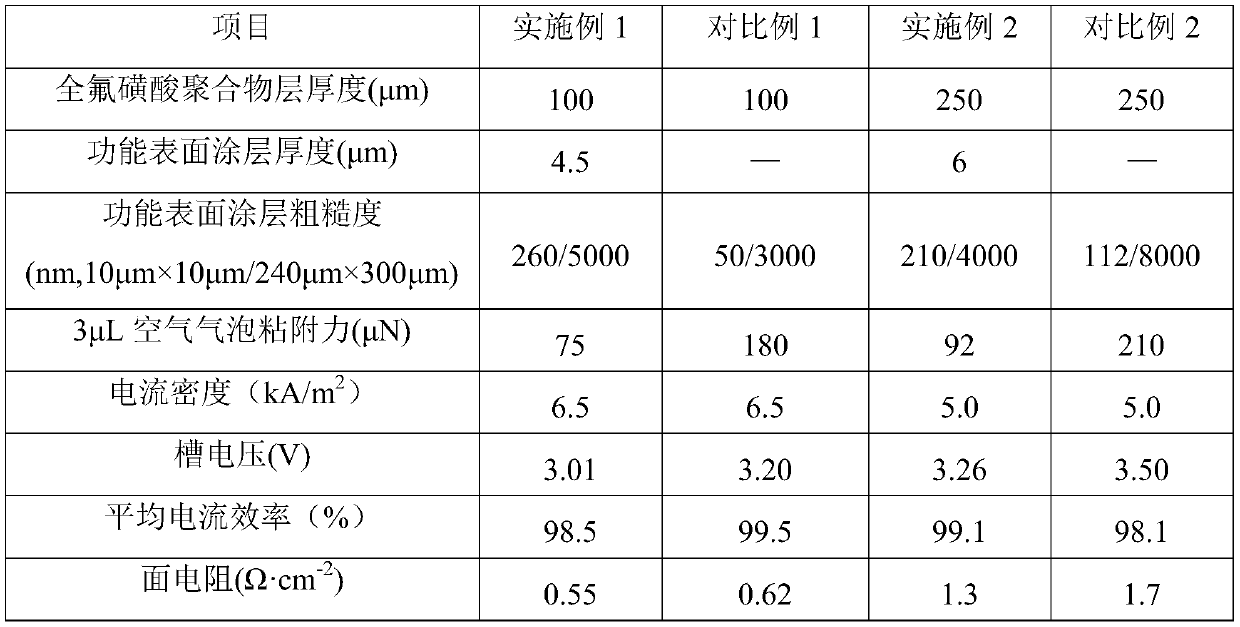

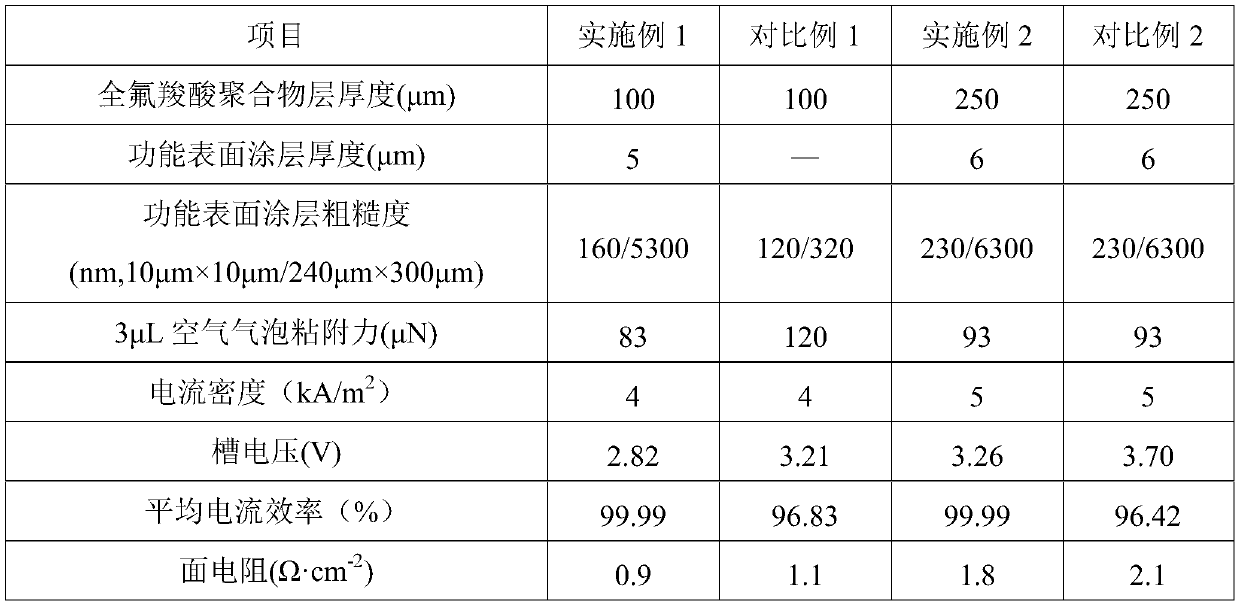

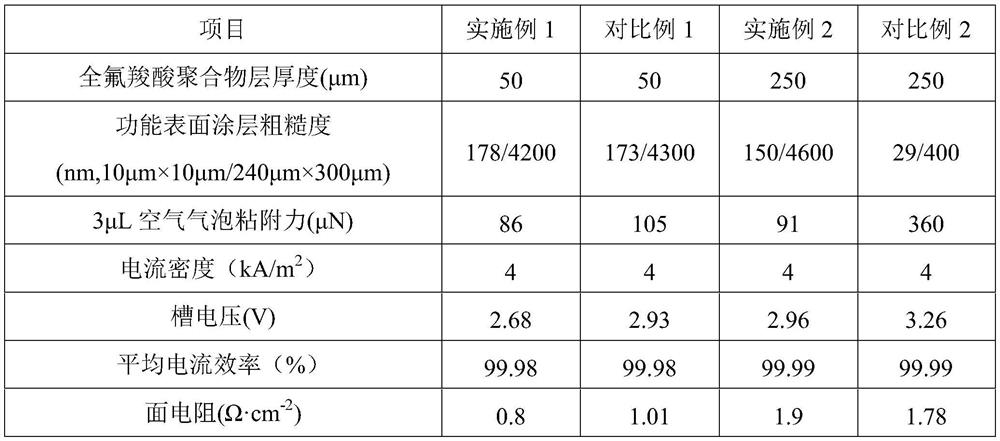

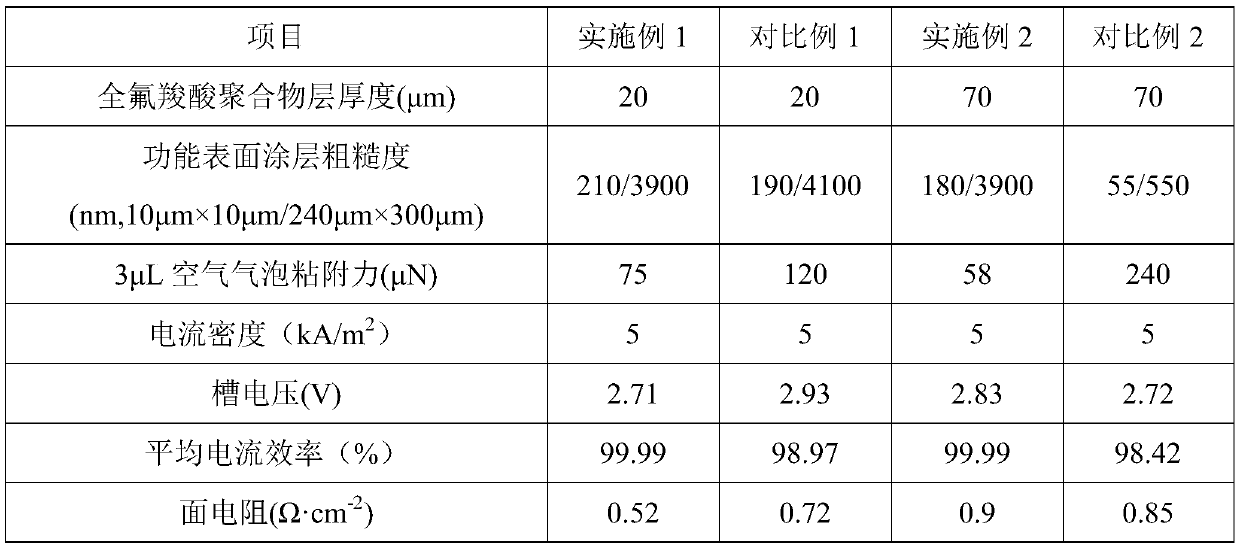

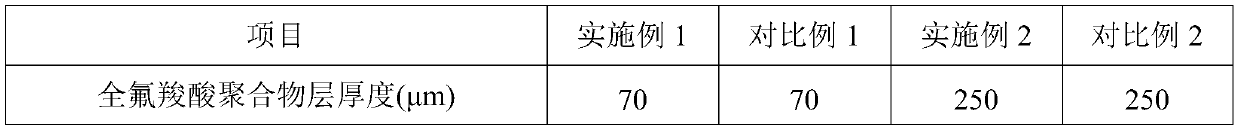

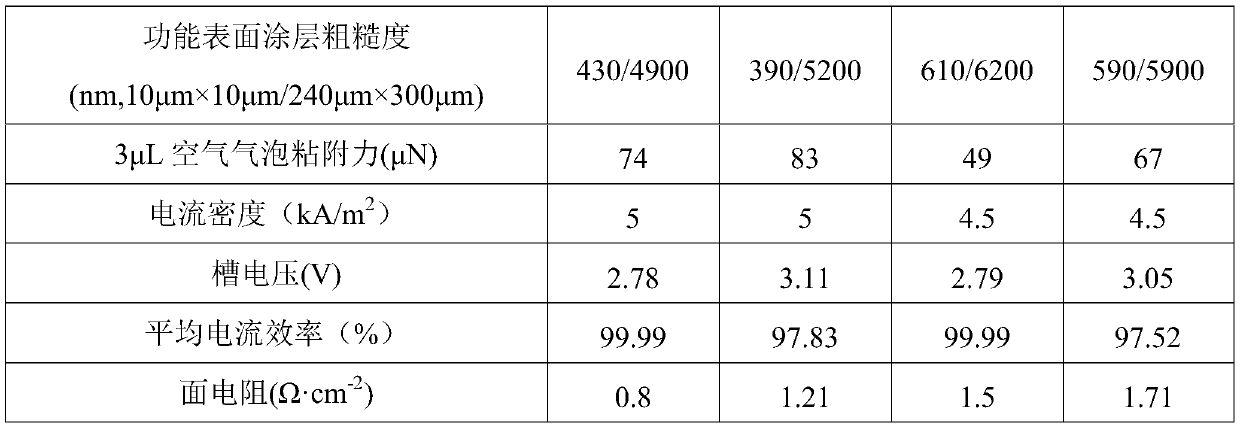

Reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis, and preparation method thereof

InactiveCN111188065AImprove mechanical propertiesLow film resistanceOrganic diaphragmsFilm resistancePhysical chemistry

The invention belongs to the technical field of ion exchange membranes, and particularly relates to a reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis, and a preparation method thereof. The perfluorosulfonic acid ion exchange membrane comprises a perfluorosulfonic acid polymer layer, wherein the surface of the perfluorosulfonic acid polymer layer is coated with a functional surface coating, the functional surface coating is composed of a perfluoropolymer and has a porous rough structure, a reinforcing material layer is embedded in the perfluorosulfonic acid polymer layer, and the reinforcing material layer is provided with a hollow tunnel structure. According to the invention, a perfluoropolymer reinforcing net is added in a perfluorosulfonic acid base membrane while a hollow tunnel is prepared in the membrane, so that the membrane has good mechanical property and low film resistance; a perfluorinated ionic polymer with ion conduction function is adopted to replace the perfluorinated sulfonic acid coating containing the metal oxide in the existing product, and the formed porous channel can improve the surface roughness of the membrane so as to improve the anti-foaming performance of the membrane.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Composite additive for industrial gear oil

InactiveCN103725367ASimple preparation protocolImprove thermal stabilityAdditivesHigh resistanceEnvironmental resistance

The invention relates to a composite additive for industrial gear oil. The composite additive for industrial gear oil is basically characterized by comprising, by weight, 9-11% of an antioxidant; 8-10% of an antiwear agent; 10-12% of an anti-extreme pressure agent; 9-11% of a demulsifying agent; 10-12% of a foam inhibitor; 4-6% of a pour-point depressant; 4-6% of a tackifier; 3-4% of nanoscale copper oxide powder; 4-5% of nanoscale magnesium powder; and the balance base oil. The antioxidant is sterically hindered phenol; the antiwear agent is dialkyl dithiophosphate; the anti-extreme pressure agent is chlorinated paraffin; the demulsifying agent is polyalkoxyl polyol; the foam inhibitor is polyacrylic ester; the pour-point depressant is polyalkyl methacrylate; and the tackifier is polyisobutylene. Being economical and practical, the composite additive for industrial gear oil provided by the invention has the advantages of simple preparation scheme, strong thermal stability, good high temperature extrusion performance, strong oxidation resistance and high wear resistance, can prolong the demulsibility life, and can enhance the anti-foaming performance, and is superior to similar products in terms of comprehensive performance. The waste oil is degradable, thus improving the environmental protection requirements.

Owner:TIANJIN ZEYA TECH

Composite agent for engine oil

InactiveCN102477342AExtend the life cycleImprove wear resistanceAdditivesAntioxidantMaterials science

The invention relates to a composite agent for engine oil. The composite agent comprises, by weight, 10-12% of a dispersant, 11-12% of a detergent, 7-9% of a wear resisting agent, 13-14% of an antioxidant, 5-6% of a viscosity index improver, 4-5% of a pour point depressant, 7-8% of a defoamer, 9-11% of a demulsifying agent, 1-2% of metallic chromium powder, and the balance base oil, wherein the dispersant is polyisobutylene bissuccinimide; the detergent is a phenate; the wear resisting agent is a metal dialkyl dithiophosphyl dithiophosphate; the antioxidant is acrylate; the viscosity index improver is polymethacrylate; the pour point depressant is alkylnaphthalene; the defoamer is polydimethylsiloxane; and the demulsifying agent is a polyalkoxy polyol. A manufacturing method of the composite agent of the invention is simple, economic and utile; and the prepared composite agent has the advantages of low price, high quality, prolongation of the service period of lubricating oil, improvement of the wear resistance and the extreme pressure resistance of the lubricating oil, improvement of various efficacies of the oxidation resistance, the corrosion resistance and the foaming resistance of the lubricating oil, and permanent maintenance of the clean effect of the lubricating oil, so comprehensive efficacies of the lubricating oil are comprehensively improved.

Owner:TIANJIN GONGBO SCI TECH DEV

Preparation method for gear oil composite additive

InactiveCN103725362ASimple preparation protocolStrong thermal stabilityAdditivesEnvironmental resistanceMagnesium

The invention relates to a preparation method for a gear oil composite additive. The gear oil composite additive is basically characterized by comprising, by weight, 6-8% of a rusting inhibitor; 8-10% of an antiwear additive; 4-6% of an extreme pressure additive; 4-5% of a solid extreme pressure additive;7-8% of a demulsifying agent; 7-9% of a foam inhibitor; 4-5% of a viscosity index improver; 4-5% of a metal deactivator; 6-7% of boron powder; 4-6% of metal magnesium powder; and the balance base oil. Being economical and practical, the gear oil composite additive provided by the invention has the advantages of simple preparation scheme, strong thermal stability, good high temperature extreme pressure performance, strong oxidation resistance and high wear resistance, can prolong the demulsification life, and can enhance the anti-blistering performance, and the comprehensive performance is stronger than that of similar products. The waste oil can be degradable, thus enhancing the environmental protection requirements.

Owner:TIANJIN ZEYA TECH

Compound additive of engine oil

The invention provides a compound additive of an engine oil. The compound additive of the engine oil is characterized by comprising a base oil, a dispersing agent, a cleansing agent, an anti-wear agent, an antioxidant, a viscosity index improver, a pour point depressant, an anti-foaming agent, a demulsifying agent and copper oxide. The dispersing agent is polyisobutene-bis-succinimide; the cleansing agent is petroleum calcium sulfonate; the anti-wear agent is alkyl containing phosphate and salt; the antioxidant is diarylamine; the viscosity index improver is ethylene-propylene copolymer; the pour point depressant is polyalkyl methacrylate; the anti-foaming agent is dimethyl siloxane polymer; and the demulsifying agent is polyalkoxy phenol. The components comprise 8-9% of dispersing agent, 10-12% of cleansing agent, 10-12% of anti-wear agent, 9-11% of antioxidant, 4-5% of viscosity index improver, 4-5% of pour point depressant, 4-5% of anti-foaming agent, 6-7% of demulsifying agent, 2-3% of titanium oxide and the balance of base oil in percentage by weight. The compound additive of the engine oil, provided by the invention, has the advantages of simple manufacturing method, economic efficiency, practicability, low price of the manufactured product, high quality, capability of prolonging the life cycle of the lubricating oil, improving the anti-wear and extreme pressure resistant effects of the lubricating oil and enhancing multiple effects of oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil, long-term retention of cleansing effect of the lubricating oil and capability of comprehensively enhancing the comprehensive effect of the engine lubricating oil.

Owner:TIANJIN GONGBO SCI TECH DEV

Composite additive used for industrial gear oil

InactiveCN103725349ASimple preparation protocolImprove thermal stabilityAdditivesHigh resistanceWaste oil

The invention relates to a composite additive used for industrial gear oil. The composite additive is basically characterized by comprising, by weight, 7-9% of an antioxidant; 6-8% of an anti-abrasion agent; 5-6% of a metal deactivator; 5-7% of an antiwear agent; 4-6% of an extreme pressure agent; 8-10% of a demulsifying agent; 4-5% of a friction modifier; 5-7% of a pour point depressant; 8-10% of a foam inhibitor; 8-10% of metal magnesium powder; 4-6% of graphite, and the balance base oil. Being economical and practical, the composite additive used for industrial gear oil provided by the invention has the advantages of simple preparation scheme, strong thermal stability, good high temperature extrusion performance, strong oxidation resistance, and high wear resistance, can prolong the demulsibility life, also can enhance the anti-foaming performance, and has comprehensive performance superior to that of similar products. The waste oil is degradable, thus improving the environmental protection requirements.

Owner:TIANJIN ZEYA TECH

Composite additive applied to engine oil

InactiveCN105886013ASimple manufacturing methodExtend the life cycleAdditivesViscosity indexAntioxidant

The invention relates to a composite additive applied to engine oil. The composite additive is composed of base oil, an antioxidant, a dispersant, a cleaning agent, a corrosion inhibitor, a foaming inhibitor, a metal passivator, a demulsifying agent, a viscosity index improver, an extreme pressure additive, tungsten oxide powder, and molybdenum oxide powder. The composite additive has the advantage of simple production method, waste oil is biodegradable, an environmental protection requirement is completely reached, the usage period of a product is longer, antiwear and anti-extreme pressure efficacies of lubricating oil are improved; a plurality of efficacies of oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are increased simultaneously, a cleanliness efficacy of the lubricating oil can be maintained for a long term, and the comprehensive efficacy of the lubricating oil of an engine can be completely enhanced.

Owner:TIANJIN ZECHANG TECH

Composite additive used for turbine oil

InactiveCN105602662AImproves anti-wear and extreme pressure performanceImprove oxidation resistanceAdditivesViscosity indexCorrosion inhibitor

Owner:TIANJIN ZECHANG TECH

Composite additive for turbine oil

InactiveCN103773562AHigh performance requirementsImprove extreme pressure performanceAdditivesSludgeAlkylphenol

The invention discloses a composite additive for turbine oil. The composite additive comprises base oil, an anti-oxidant, a rusting inhibitor, a foam inhibitor, a metal deactivator, an extreme pressure additive, a demulsification agent, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of diarylamine and alkylphenol. The rusting inhibitor is an alkylsuccinic acid derivative. The foam inhibitor is polydimethylsiloxane. The metal deactivator is triazole. The extreme pressure additive comprises alkyl phosphate ester and salt. The demulsification agent is polyalkoxypolyamine. The composite additive comprises, by weight, 12-14% of the anti-oxidant, 9-11% of the rusting inhibitor, 7-9% of the foam inhibitor, 10-12% of the metal deactivator, 6-8% of the extreme pressure additive, 11-13% of the demulsification agent, 1-2% of the copper oxide powder, 1-2% of the magnesium metal powder and the balance the base oil. The composite additive is prepared by the simple processes, has a price lower than those of the same types of other products, has high quality, effectively and comprehensively improves performances of the turbine oil, prolongs a use period of the turbine oil, improves turbine oil extreme pressure resistance, comprehensively improves oxidation resistance, corrosion resistance, foam resistance and oily sludge resistance of the turbine oil, is biodegradable and completely exceeds environmental requirements on the same type of products.

Owner:TIANJIN ZEYA TECH

Compounded additive applied to turbine oil

InactiveCN105886026ASimple manufacturing methodExtend the life cycleAdditivesCorrosionViscosity index

The invention relates to a compounded additive applied to turbine oil. The compounded additive is prepared from base oil, an antioxidant, a dispersant, a detergent, a rust inhibitor, a foam inhibitor, a metal deactivator, a demulsifier, a viscosity index improver, an extreme pressure additive, tungsten oxide powder and molybdenum oxide powder. According to the compounded additive, the preparation method is simple, waste oil is biodegradable, the environment-friendly requirements are fully met, and the use cycle of the product is longer; and the antiwear and extreme pressure resisting effects of lubricating oil are improved, meanwhile, multiple functions, i.e., oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are improved, and the detergency effect of the lubricating oil is kept durably, so that the comprehensive effect of the engine lubricating oil can be fully improved.

Owner:TIANJIN ZECHANG TECH

Complexing agent for lubricating oil for engines

The invention discloses a complexing agent for lubricating oil for engines, comprising 10-12 wt% of dispersant, 10-11 wt% of detergent, 6-7 wt% of anti-wear agent, 13-14 wt% of anti-oxidant, 4-5 wt% of viscosity index improver, 5-6 wt% of pour-point depressant, 7-8 wt% of anti-foaming agent, 11-13wt% of anti-creaming agent, 1-2 wt% of magnesium powder, 1-2 wt% of boron powder and the balance of base oil, wherein the dispersant is polyisobutylene succinimide, the detergent is thiophosphate, the anti-wear agent is dialkyl-disulphophosphate, the anti-oxidant is dialkyl sulfide, the viscosity index improver is polyalkyl methacrylate, the pour-point depressant is polyfumaric acid, the anti-foaming agent is acrylic acid alkyl ester copolymer, and the anti-creaming agent is polyalkyloxy phenol. According to the invention, the production method is simple, economical and practical; the produced product has the advantages of low price and high quality, can prolong the life cycle of the lubricating oil, increase the anti-wear and anti-extreme pressure efficiency, raise the effects of oxidation resistance, corrosion resistance, and foaming resistance of the lubricating oil, and keep the cleanliness of the lubricating oil for a long time, and can comprehensively improve the comprehensive efficiency of the lubricating oil for engines.

Owner:TIANJIN GONGBO SCI TECH DEV

Ultrathin perfluorosulfonic acid ion exchange membrane for alkali metal chloride electrolysis, and preparation method thereof

ActiveCN111188050AImprove mechanical propertiesLow film resistanceOrganic diaphragmsPhysical chemistryIon-exchange membranes

The invention belongs to the technical field of ion exchange membranes, and particularly relates to an ultrathin perfluorosulfonic acid ion exchange membrane for alkali metal chloride electrolysis, and a preparation method thereof. The ultrathin perfluorosulfonic acid ion exchange membrane comprises a perfluorosulfonic acid polymer layer, wherein the surface of the perfluorosulfonic acid polymer layer is coated with a functional surface coating, the functional surface coating is composed of a perfluoropolymer and has a porous rough structure, and a porous non-woven polymer layer is embedded inthe perfluorosulfonic acid polymer layer. According to the invention, an ultrathin porous non-woven polymer is used as a reinforcing material, so that the membrane has good mechanical properties andlow membrane resistance; by adopting a perfluorosulfonic acid polymer with ion conduction function, the surface roughness of the membrane can be improved so as to improve the anti-foaming performanceof the membrane, so that the membrane is suitable for running in a zero-polar-distance electrolytic cell under a novel high-current-density condition, and the cell voltage can be remarkably reduced; and the preparation method provided by the invention is simple and reasonable in process and easy for industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Tungsten-molybdenum alloy antiwear additive for engine oil

InactiveCN104178243ALong-term wear resistanceLong-term anti-extreme pressure effectAdditivesPhosphateAntioxidant

A tungsten-molybdenum alloy antiwear additive for an engine oil is composed of a base oil, a tungsten-molybdenum alloy, an antioxidant, a clearing agent, a dispersant, a metal deactivator, an extreme-pressure additive and lecithin. The antioxidant is dioctyl diphenylamine; the clearing agent is calcium-based phenolate; the dispersant is succinimide; the metal deactivator is benzotriazole; the extreme-pressure additive is alkyl containing phosphate and salt. A manufacturing method is simple, requirements of environmental protection are fully met, the product use cycle is longer, antiwear and extreme pressure resistant efficacies of the lubricating oil are improved, at the same time, various efficacies of oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are improved, a clean effect of the lubricating oil is kept for a long time, and the comprehensive efficacies of the engine lubricating oil can be completely enhanced.

Owner:TIANJIN ZECHANG TECH

Composite additive for industrial gear oil

InactiveCN103725364ASimple preparation protocolImprove thermal stabilityAdditivesEnvironmental resistanceDepressant

The invention relates to a composite additive for industrial gear oil. The composite additive for industrial gear oil is basically characterized by comprising, by weight, 7-8% of an antioxidant; 6-8% of a rusting inhibitor; 7-9% of a metal passivator; 8-10% of an antiwear agent; 7-9% of an anti-extreme pressure agent; 8-10% of a demulsifying agent; 2-3% of a pour point depressant; 3-5% of a friction modifier; 6-8% of a foam inhibitor; 12-14% of nanoscale metal magnesium powder; and the balance base oil. Being economical and practical, the composite additive for industrial gear oil provided by the invention has the advantages of simple preparation scheme, strong thermal stability, good high temperature extrusion performance, strong oxidation resistance and high wear resistance, can prolong the demulsibility life, and can enhance the anti-foaming performance, and is superior to similar products in terms of comprehensive performance. The waste oil is degradable, thus improving the environmental protection requirements.

Owner:TIANJIN ZEYA TECH

Reinforced perfluorocarboxylic acid ion exchange membrane with bubble thinning function and preparation method thereof

InactiveCN111118543AHinder reverse migrationSmall ion channelOrganic diaphragmsPhysical chemistryCarboxylic acid

The invention belongs to the technical field of ion exchange membranes, and particularly relates to a reinforced perfluorocarboxylic acid ion exchange membrane with a bubble dredging function and a preparation method thereof. The reinforced perfluorocarboxylic acid ion exchange membrane with the bubble thinning function is composed of a perfluorocarboxylic acid polymer layer, a porous reinforcingmaterial layer and functional surface coatings, the functional surface coatings are located on the upper surface and the lower surface of the perfluorocarboxylic acid polymer layer, the porous reinforcing material layer is embedded in the perfluorocarboxylic acid polymer layer, and the functional surface coating is of a porous rough structure composed of a perfluorinated ionic polymer. The reinforced perfluorocarboxylic acid ion exchange membrane with the bubble thinning function can effectively reduce the cell voltage, reduce the electrolysis energy consumption and reduce the production costin a novel zero-polar-distance electrolytic cell under the condition of high current density, and is suitable for the field of electrolysis of sodium chloride and potassium chloride; the invention also provides a preparation method thereof.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Complexing agent used in engine oil

InactiveCN104178261AMeet high performance requirementsImprove oxidation resistanceAdditivesRheniumPhosphate

A complexing agent used in engine oil consists of base oil, an antioxidant, a corrosion inhibitor, a dispersant, a metal passivator, an extreme pressure additive, a detergent, a viscosity index improver, a metal molybdenum powder and a metal rhenium powder. The antioxidant is a mixture of hindered bisphenol and aromatic amine; the corrosion inhibitor is ethoxy phenol; the dispersant is succimide; the metal passivator is benzotriazole; the extreme pressure additive is molybdenum salt of phosphate; the detergent is borate; and the viscosity index improver is poly alkylmethacrylate. The manufacturing method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil, prolong usage period of the lubricant, improve anti extreme pressure efficacy of the lubricating oil, and comprehensively enhance the oxidation resistance, corrosion resistance, foaming resistance and sludge resistance of the lubricating oil, so as to improve the comprehensive efficacy.

Owner:TIANJIN ZECHANG TECH

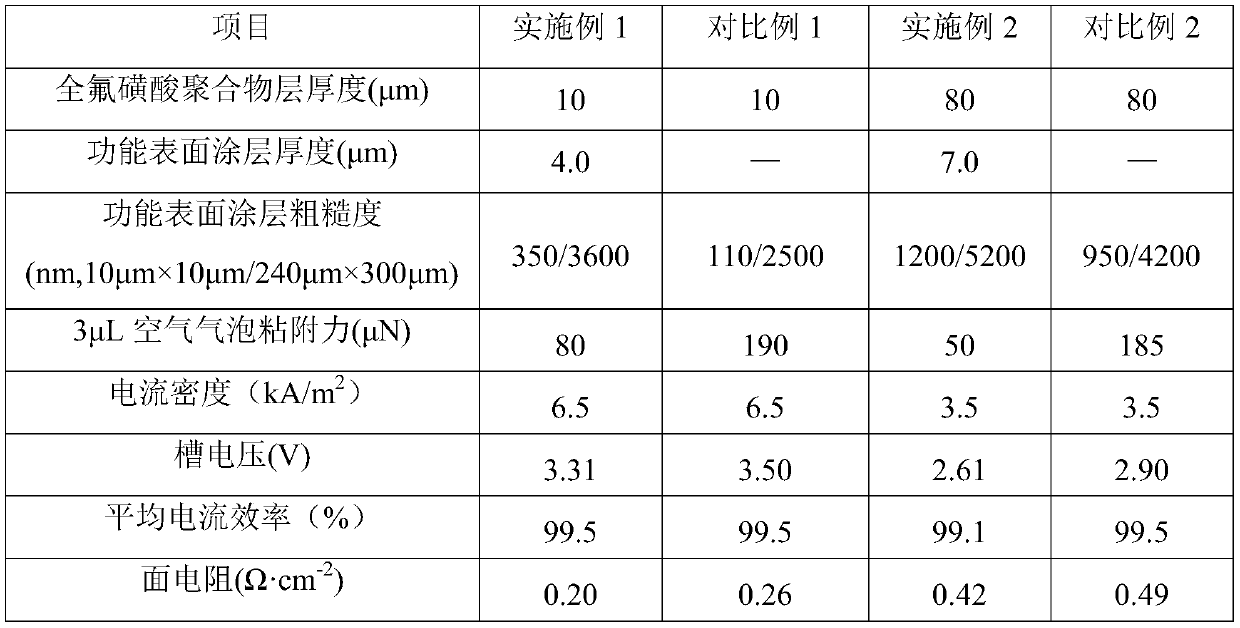

Perfluorocarboxylic acid ion exchange membrane with rough coating and method for its preparation

ActiveCN111101152BHinder reverse migrationSmall ion channelOrganic diaphragmsPhysical chemistryCarboxylic acid

The invention belongs to the technical field of ion exchange membranes, in particular to a perfluorocarboxylic acid ion exchange membrane with a rough coating and a preparation method thereof. The perfluorocarboxylic acid ion exchange membrane with rough coating of the present invention is composed of a perfluorocarboxylic acid polymer layer and a functional surface coating, wherein the functional surface coating is located on the upper and lower surfaces of the perfluorocarboxylic acid polymer layer; The thickness of the perfluorocarboxylic acid polymer layer is 50-250 μm, and the thickness of the functional surface coating is 10nm-30 μm; the functional surface coating is a porous rough structure composed of a mixture of perfluoroionic polymers and metal oxides. structure. The perfluorocarboxylic acid ion-exchange membrane with a rough coating of the present invention can effectively reduce the cell voltage, reduce electrolysis energy consumption, and reduce production costs in a zero-pole pitch electrolytic cell under novel high current density conditions; the present invention also provides its preparation method.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Compound additive for turbine oil

InactiveCN105886009AImprove wear resistanceImprove extreme pressure performanceAdditivesAntioxidantWaste oil

The invention relates to a compound additive for turbine oil. The compound additive is prepared from base oil, an antioxidant, a dispersant, a detergent, a rust inhibitor, a foam inhibitor, a metal deactivator, a demulsifier, a viscosity index improver, an extreme pressure additive, tungsten oxide powder and molybdenum oxide powder. According to the compound additive, the preparation method is simple, waste oil is biodegradable, the environment-friendly requirements are fully met, and the use cycle of the product is longer; and the antiwear and extreme pressure resisting effects of lubricating oil are improved, meanwhile, multiple functions, i.e., oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are improved, and the detergency effect of the lubricating oil is kept durably, so that the comprehensive effect of the engine lubricating oil can be fully improved.

Owner:TIANJIN ZECHANG TECH

Nano-metal composite additive applied to turbine oil

InactiveCN104178259AHigh performance requirementsImprove oxidation resistanceAdditivesRheniumAntioxidant

The invention discloses a nano-metal composite additive applied to turbine oil. The nano-metal composite additive is characterized by consisting of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivator, an extreme pressure additive, a demulsification agent, metal molybdenum powder, metal rhenium powder and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is polyisobutene maleimide; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Tungsten-molybdenum alloy antiwear additive added in engine oil

InactiveCN104178292ALong-term wear resistanceLong-term anti-extreme pressure effectLubricant compositionPhosphoric Acid EstersPhosphate

A tungsten-molybdenum alloy antiwear additive added in an engine oil is composed of a base oil, a tungsten-molybdenum alloy, an antioxidant, a clearing agent, a dispersant, a metal deactivator, an extreme-pressure additive and lecithin. The antioxidant is phosphoric acid ester; the clearing agent is phosphate; the dispersant is succinate; the metal deactivator is benzotriazole; the extreme-pressure additive is alkyl containing phosphate and salt. A manufacturing method is simple, requirements of environmental protection are fully met, the product use cycle is longer, antiwear and extreme pressure resistant efficacies of a lubricating oil are improved, at the same time, various efficacies of oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are improved, a clean effect of the lubricating oil is kept for a long time, and the comprehensive efficacies of the engine lubricating oil can be completely enhanced.

Owner:TIANJIN ZECHANG TECH

Tungsten molybdenum alloy anti-wear additive used in engine lubricating oil

InactiveCN104178294ALong-term wear resistanceLong-term anti-extreme pressure effectLubricant compositionAntioxidantAlloy

A tungsten molybdenum alloy anti-wear additive used in engine lubricating oil comprises base oil; tungsten molybdenum alloy; an antioxidant; a detergent; a dispersant; a metal passivator; an extreme pressure additive; and lecithin. The antioxidant is tributyl phosphite, the detergent is borate, the dispersant is succinate, the metal passivator is benzotriazole, and the extreme pressure additive is alkyl phosphorus containing acid ester and salt. The tungsten molybdenum alloy anti-wear additive is simple in manufacturing method, and can fully meet the requirements of environmental protection, the product use cycle is longer, lubricating oil antiwear and anti extreme pressure effects are improved, oxidation resistance, corrosion resistance, foaming resistance and other various effects of the lubricating oil can be improved, the detergency effect of the lubricating oil can be kept for a long time, and the comprehensive effects of engine lubricating oil can be fully enhanced.

Owner:TIANJIN ZECHANG TECH

Compounded additive for turbine oil

InactiveCN105886010AImprove wear resistanceImprove extreme pressure performanceAdditivesMaterials scienceRust

The invention relates to a compounded additive for turbine oil. The compounded additive is prepared from base oil, an antioxidant, a dispersant, a detergent, a rust inhibitor, a foam inhibitor, a metal deactivator, a demulsifier, a viscosity index improver, an extreme pressure additive, tungsten oxide powder and molybdenum oxide powder. According to the compounded additive, the preparation method is simple, waste oil is biodegradable, the environment-friendly requirements are fully met, and the use cycle of the product is longer; and the antiwear and extreme pressure resisting effects of lubricating oil are improved, meanwhile, multiple functions, i.e., oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are improved, and the detergency effect of the lubricating oil is kept durably, so that the comprehensive effect of the engine lubricating oil can be fully improved.

Owner:TIANJIN ZECHANG TECH

Nano-metal composite additive applied to turbine oil

InactiveCN104178316AHigh performance requirementsImprove oxidation resistanceLubricant compositionRheniumAntioxidant

The invention discloses a nano-metal composite additive applied to turbine oil. The nano-metal composite additive consists of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivator, an extreme pressure additive, a demulsification agent, metal molybdenum powder, metal rhenium powder and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is a Mannich base ashless dispersant; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Ultrathin perfluorocarboxylic acid ion exchange membrane with rough coating and preparation method of same

ActiveCN111118542AHinder reverse migrationSmall ion channelOrganic diaphragmsTextiles and paperPhysical chemistryCarboxylic acid

The invention belongs to the technical field of ion exchange membranes, and particularly relates to an ultrathin perfluorocarboxylic acid ion exchange membrane with a rough coating and a preparation method of the same. The ultrathin perfluorocarboxylic acid ion exchange membrane with the rough coating is composed of a perfluorocarboxylic acid polymer layer, a porous non-woven polymer layer and functional surface coatings, wherein the functional surface coatings are located on the upper surface and the lower surface of the perfluorocarboxylic acid polymer layer, and the porous non-woven polymerlayer is embedded in the perfluorocarboxylic acid polymer layer; the thickness of the perfluorocarboxylic acid polymer layer is 10-80 [mu]m; the functional surface coating is of a porous rough structure formed by a mixture of a perfluorinated ionic polymer and a metal oxide. According to the invention, the ultrathin perfluorocarboxylic acid ion exchange membrane has the rough coating, so that thecell voltage can be effectively reduced, the electrolysis energy consumption can be reduced, and the production cost can be reduced in a novel zero-polar-distance electrolytic cell under the condition of high current density; the invention also provides a preparation method thereof.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

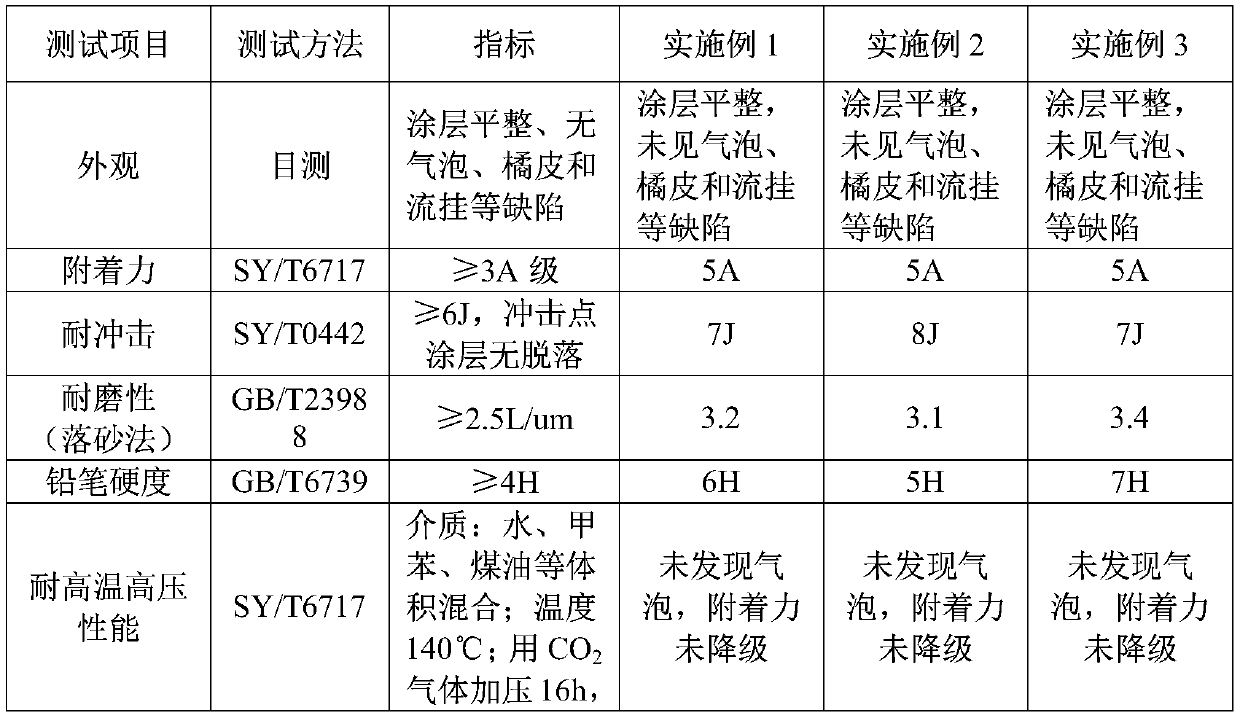

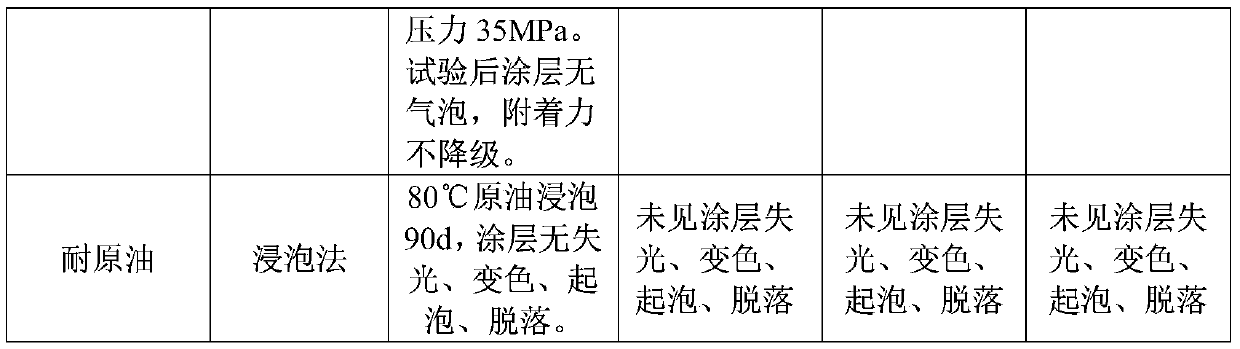

Coating for oil extraction well pipe of electric submersible pump, preparation method and application

InactiveCN110283518AImprove heat resistanceImproves anti-foamingFireproof paintsPretreated surfacesMaterials scienceDefoamer

The invention provides an anticorrosive powder coating special for an oil extraction well pipe of an oil field electric submersible pump, a preparation method and application. The powder coating is resistant to high temperature and blistering, is good in anti-corrosion performance, and is especially suitable for the use requirements of the oil extraction well pipe of the electric submersible pump in complicated environmental media. The powder coating is prepared from the following raw materials in parts by weight: 35-60 parts of phenolic epoxy resin, 20-35 parts of alicyclic epoxy resin, 20-35 parts of a curing agent, 15-20 parts of feldspar powder, 5-20 parts of barium sulfate, 10-30 parts of mica powder, 25-65 parts of a high-temperature-resistant and corrosion-resistant material, 0.8-3 parts of an acrylate copolymer leveling agent, 0.5-3 parts of a curing accelerator, 0.5-2 parts of a defoamer, and 1-3 parts of a wetting agent.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Tungsten molybdenum alloy anti-wear additive used in engine oil

InactiveCN104178296AImprove wear resistanceImprove extreme pressure performanceAdditivesAntioxidantPhosphate

A tungsten molybdenum alloy anti-wear additive used in engine lubricating oil comprises base oil; tungsten molybdenum alloy; an antioxidant; a detergent; a dispersant; a metal passivator; an extreme pressure additive; and lecithin. The antioxidant is dialkyl dithiophosphate, the detergent is naphthenate, the dispersant is ash-free phosphate, the metal passivator is benzotriazole, and the extreme pressure additive is alkyl phosphorus-containing acid ester and salt. The tungsten molybdenum alloy anti-wear additive is simple in manufacturing method, and can fully meet the requirements of environmental protection, the product use cycle is longer, lubricating oil antiwear and anti extreme pressure effects are improved, oxidation resistance, corrosion resistance, foaming resistance and other various effects of the lubricating oil can be improved, the detergency effect of the lubricating oil can be kept for a long time, and the comprehensive effects of engine lubricating oil can be fully enhanced.

Owner:TIANJIN ZECHANG TECH

Reinforced perfluorocarboxylic acid ion exchange membrane with rough coating, and preparation method thereof

InactiveCN111188062AImprove electrolysis current efficiencyIncreased durabilityOrganic diaphragmsIon-exchange membranesElectrolytic cell

The invention belongs to the technical field of ion exchange membranes, and particularly relates to a reinforced perfluorocarboxylic acid ion exchange membrane with a rough coating, and a preparationmethod thereof. The reinforced perfluorocarboxylic acid ion exchange membrane is composed of a perfluorocarboxylic acid polymer layer, a porous reinforcing material layer and functional surface coatings, wherein the functional surface coatings are located on the upper surface and the lower surface of the perfluorocarboxylic acid polymer layer, the porous reinforcing material layer is embedded in the perfluorocarboxylic acid polymer layer, and the functional surface coating is of a porous rough structure composed of a perfluorinated ionic polymer and a metal oxide. The reinforced perfluorocarboxylic acid ion exchange membrane with the rough coating can effectively reduce the cell voltage, reduce the electrolysis energy consumption and reduce the production cost in a novel zero-polar-distance electrolytic cell under the condition of high current density, and is suitable for the field of electrolysis of sodium chloride and potassium chloride. The invention also provides a preparation method of the reinforced perfluorocarboxylic acid ion exchange membrane.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Composite additive applied to turbine oil

InactiveCN105886015AImprove wear resistanceImprove extreme pressure performanceAdditivesEnvironmental resistanceCleansing Agents

The invention relates to a composite additive applied to turbine oil. The composite additive is composed of base oil, an antioxidant, a dispersant, a cleaning agent, a corrosion inhibitor, a foaming inhibitor, a metal passivator, a demulsifying agent, a viscosity index improver, an extreme pressure additive, tungsten oxide powder, and molybdenum oxide powder. The composite additive has the advantage of simple production method, waste oil is biodegradable, an environmental protection requirement is completely reached, the usage period of a product is longer, antiwear and anti-extreme pressure efficacies of lubricating oil are improved; a plurality of efficacies of oxidation resistance, corrosion resistance and foaming resistance of the lubricating oil are increased simultaneously, a cleanliness efficacy of the lubricating oil can be maintained for a long term, and the comprehensive efficacy of the lubricating oil of an engine can be completely enhanced.

Owner:TIANJIN ZECHANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com