Ultrathin perfluorocarboxylic acid ion exchange membrane with rough coating and preparation method of same

A technology of perfluorocarboxylic acid ions and rough coating, which is applied in the field of ion exchange membranes, can solve the problems of hindering ion transmission paths, increasing membrane resistance, and not conducting ions, etc., and achieves simple and reasonable process, low membrane resistance, and improved membrane surface The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

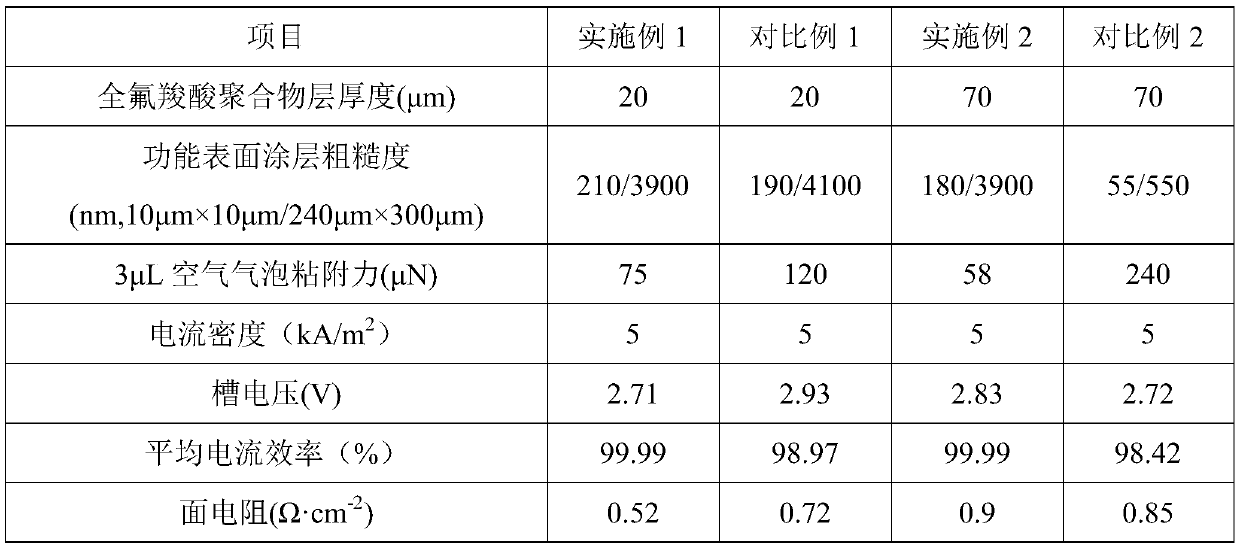

Embodiment 1

[0042] Ultrathin perfluorocarboxylic acid ion-exchange membranes with rough coatings were prepared as follows:

[0043] (1) Dissolve the perfluorocarboxylic acid resin of IEC=1.08mmol / g in a solvent made of ethanol and isopropanol in a weight ratio of 1:1 to form a perfluorocarboxylic acid resin solution, and then 8 μm thick poly The tetrafluoroethylene porous non-woven membrane was treated in the ultrasonically treated trifluorotrichloroethane solvent for 1.5h, and after it was taken out and dried, the perfluorocarboxylic acid resin solution was coated on the upper and lower surfaces of the polytetrafluoroethylene porous non-woven membrane. The total thickness of the cloth is 20 μm, and finally dried to form a perfluorocarboxylic acid ion exchange membrane precursor;

[0044](2) Under 180°C and 120t pressure, the perfluorocarboxylic acid ion exchange membrane precursor is subjected to overpressure treatment with an overpressure machine at a speed of 45m / min. After the overpre...

Embodiment 2

[0061] Ultrathin perfluorocarboxylic acid ion-exchange membranes with rough coatings were prepared as follows:

[0062] (1) Dissolve the perfluorocarboxylic acid resin of IEC=1.3mmol / g in a solvent made of ethanol and isopropanol in a weight ratio of 1:1 to form a perfluorocarboxylic acid resin solution, and then 40 μm thick poly The tetrafluoroethylene porous non-woven membrane was treated in the ultrasonically treated trifluorotrichloroethane solvent for 1.5h, and after it was taken out and dried, the perfluorocarboxylic acid resin solution was coated on the upper and lower surfaces of the polytetrafluoroethylene porous non-woven membrane. The total thickness of the cloth is 70 μm, and finally dried to form a perfluorocarboxylic acid ion exchange membrane precursor;

[0063] (2) Under 180°C and 120t pressure, the perfluorocarboxylic acid ion exchange membrane precursor is subjected to overpressure treatment with an overpressure machine at a speed of 45m / min. After the overpr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com