Perfluorocarboxylic acid ion exchange membrane with bubble thinning function and preparation method thereof

A technology of perfluorocarboxylic acid ions and perfluorocarboxylic acid, applied in the field of ion exchange membranes, can solve problems such as low current efficiency, low roughness, and limited bubble release ability, and achieve lower cell voltage, simple and reasonable process, and improved resistance The effect of foaming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

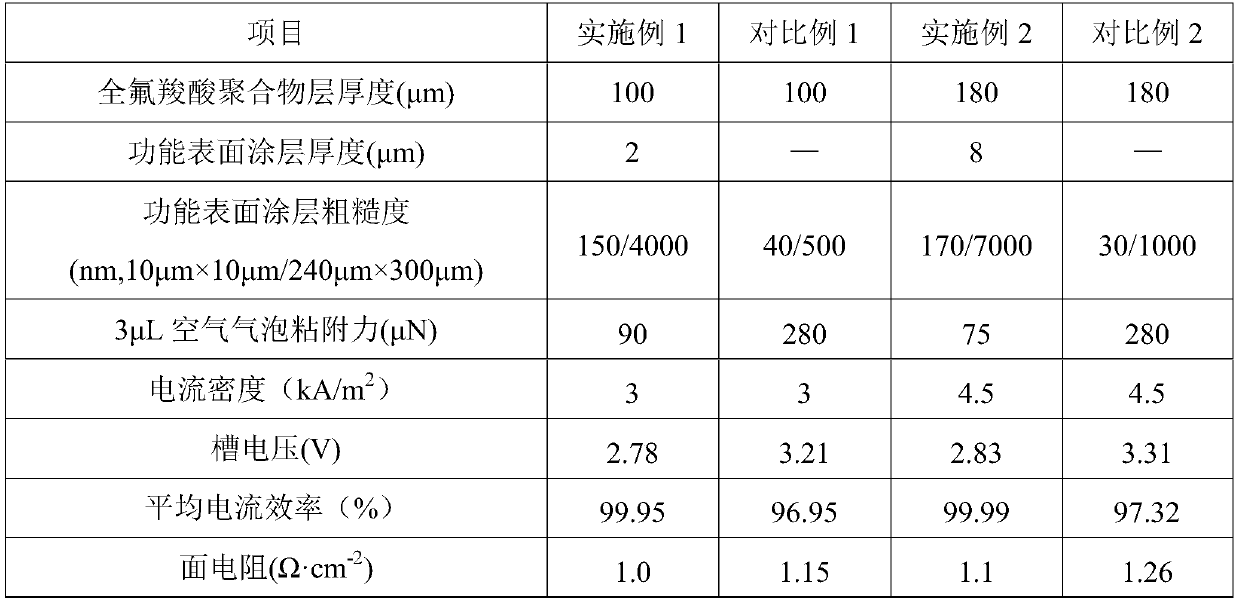

Embodiment 1

[0039] Prepare the ultra-thin perfluorocarboxylic acid ion-exchange membrane with bubble-repelling function as follows:

[0040] (1) Extrude and cast the perfluorocarboxylic acid resin of IEC=0.7mmol / g to obtain a perfluorocarboxylic acid ion-exchange resin base film with a thickness of 100 μm to form a perfluorocarboxylic acid ion-exchange membrane precursor;

[0041] (2) Under the pressure of 180°C and 120t, the perfluorocarboxylic acid ion exchange membrane precursor is subjected to overpressure treatment with an overpressure machine at a speed of 45m / min. After the overpressure treatment, it is then immersed in an alkaline solution of 85°C ( Containing 18wt% dimethyl sulfoxide, 20wt% NaOH aqueous solution) in transformation 80min, transforms into the perfluorocarboxylic acid ion-exchange membrane with ion exchange function;

[0042] (3) Add the perfluorosulfonic acid polymer with IEC=1.2mmol / g into the solvent made of ethanol and isopropanol in a weight ratio of 1:1, and t...

Embodiment 2

[0058] Prepare perfluorocarboxylic acid ion-exchange membranes with air bubble function as follows:

[0059] (1) Extrude and cast the perfluorocarboxylic acid resin of IEC=1.2mmol / g to obtain a perfluorocarboxylic acid ion-exchange resin base film with a thickness of 180 μm to form a perfluorocarboxylic acid ion-exchange membrane precursor;

[0060] (2) Under 150°C and 100t pressure, the perfluorocarboxylic acid ion-exchange membrane precursor is subjected to overpressure treatment with an overpressure machine at a speed of 45m / min. After the overpressure treatment, it is then immersed in an alkaline solution of 80°C ( Containing 15wt% dimethyl sulfoxide, 15wt% NaOH aqueous solution) in transformation 80min, transforms into the perfluorocarboxylic acid ion-exchange membrane with ion exchange function;

[0061] (3) Add the perfluorosulfonic acid polymer with IEC=1.2mmol / g into the solvent prepared by ethanol and isopropanol in a weight ratio of 1:1, and treat it in a closed rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com