Coating for oil extraction well pipe of electric submersible pump, preparation method and application

A technology for oil production wells and electric submersible pumps, applied in powder coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as steel pipe corrosion, anti-corrosion coatings are easily corroded, and electric submersible pump wells have large displacement, and achieve good heat resistance Performance and structural stability, slow down the performance of scale wax deposition, and reduce the cost of oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

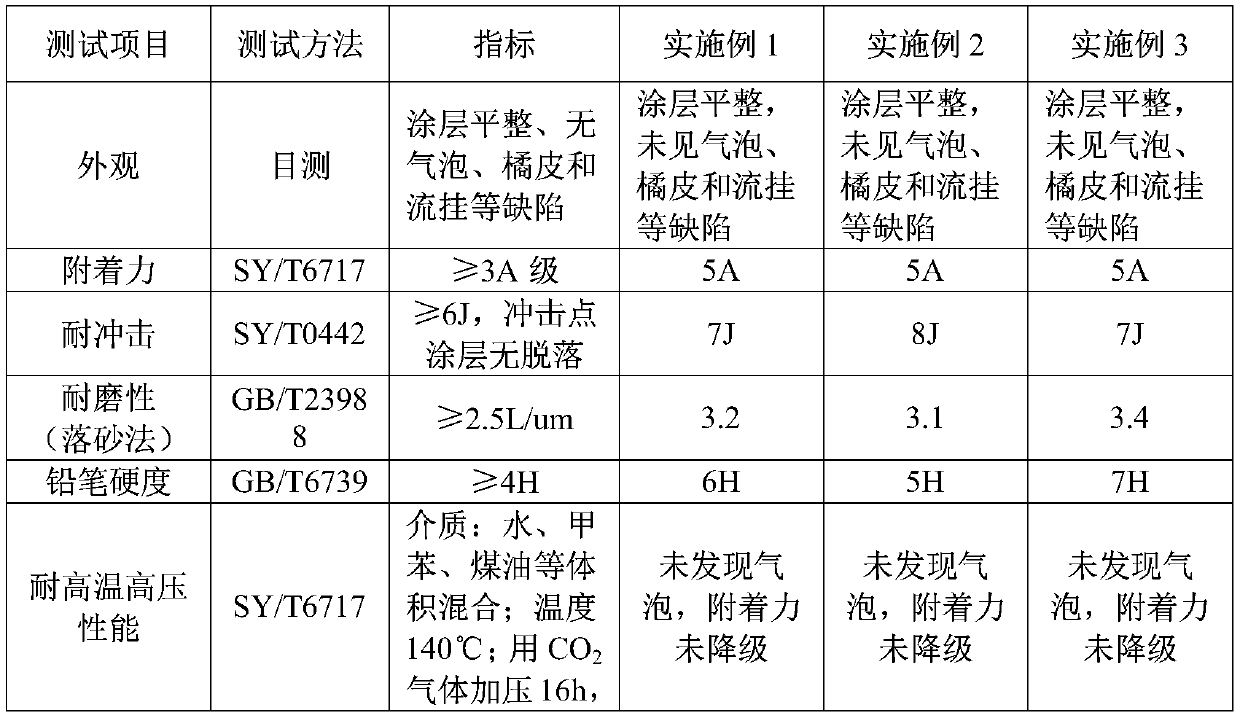

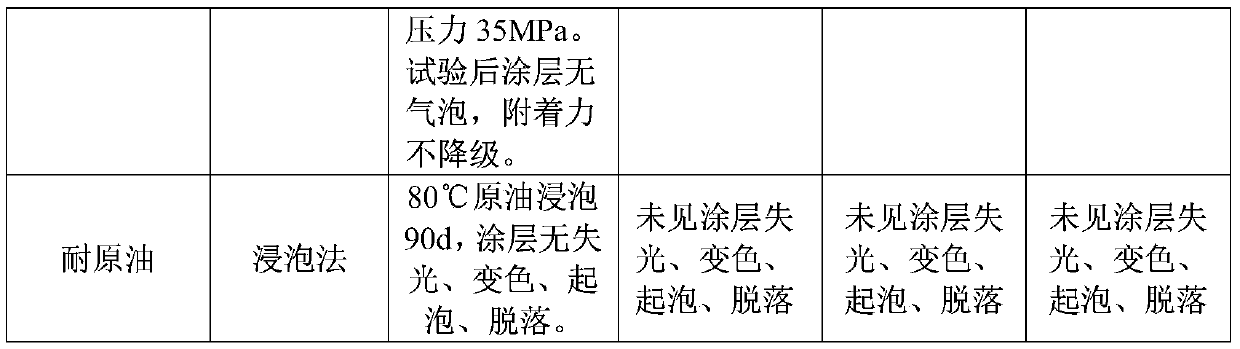

Examples

Embodiment 1

[0045] 40 parts of phenolic epoxy resin (Amanda1168), 20 parts of cycloaliphatic epoxy resin, 20 parts of curing agent, 15 parts of feldspar powder, 10 parts of barium sulfate, 15 parts of mica powder, 30 parts of zirconium dioxide, acrylate leveling agent 1.5 parts (BYK-364P), 1 part of imidazoline, 1 part of defoamer, 2 parts of wetting agent, 0.8 part of phthalocyanine green.

[0046] Put the above-mentioned raw materials in parts by weight into a high-speed crushing mixer, stir for 10 minutes, and put them into a melt extruder to press into tablets with a thickness of 1.5 mm. After air-cooling, crush and grind the powder and pass through a 120-mesh sieve to obtain a finished powder coating .

[0047] The above-mentioned prepared coating is sprayed on the inner wall of the electric submersible pump oil production well pipe, and the specific method is:

[0048] Firstly, the inner surface of the production well pipe is degreased and sandblasted. The grade of derusting treat...

Embodiment 2

[0050] 50 parts of phenolic epoxy resin (CTAB Aradur7255), 25 parts of alicyclic epoxy resin, 25 parts of curing agent, 20 parts of feldspar powder, 5 parts of barium sulfate, 10 parts of mica powder, 30 parts of titanium nitride, acrylate leveling 1.5 parts of agent (BYK-364P), 1.5 parts of imidazoline, 1 part of defoamer, 2 parts of wetting agent, 0.8 parts of bismuth vanadate molybdate yellow.

[0051] Preparation:

[0052] Put the above-mentioned raw materials in parts by weight into a high-speed crushing mixer, stir for 15 minutes, put them into a melt extruder to press into tablets with a thickness of 2mm, and after air cooling, pulverize and grind them through a 120-mesh sieve to obtain a finished powder coating.

[0053] The above-mentioned prepared coating is sprayed on the inner wall of the electric submersible pump oil production well pipe, and the specific method is:

[0054] Firstly, the inner surface of the production well pipe is degreased and sandblasted. The...

Embodiment 3

[0056] 55 parts of phenolic epoxy resin (Araldite GT7255), 30 parts of cycloaliphatic epoxy resin, 28 parts of curing agent, 15 parts of feldspar powder, 10 parts of barium sulfate, 25 parts of mica powder, 65 parts of titanium carbide, acrylate leveling agent 2.5 parts (BYK-366P), 3 parts of 2-isopropylimidazole, 2 parts of defoamer, 2 parts of wetting agent, 2 parts of phthalocyanine blue.

[0057] Preparation:

[0058] Put the above-mentioned raw materials in parts by weight into a high-speed crushing mixer, stir for 20 minutes, put them into a melt extruder to press into tablets with a thickness of 2mm, and after air cooling, pulverize and grind them through a 120-mesh sieve to obtain a finished powder coating.

[0059] The above-mentioned prepared coating is sprayed on the inner wall of the electric submersible pump oil production well pipe, and the specific method is:

[0060] Firstly, the inner surface of the production well pipe is degreased and sandblasted. The leve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com