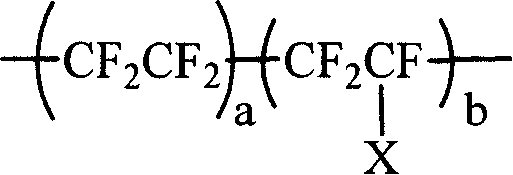

Perfluorinated ion exchange casting enhancement member and preparing method thereof

A perfluorinated ion and ion exchange technology, applied in the direction of organic diaphragm, electrolytic process, electrolytic components, etc., can solve the problems of difficult processing, easy deformation and high price of polytetrafluoroethylene mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

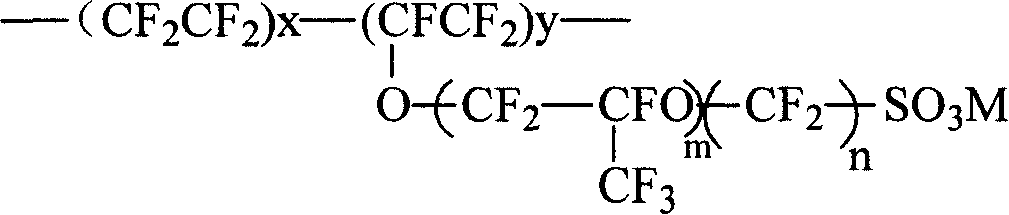

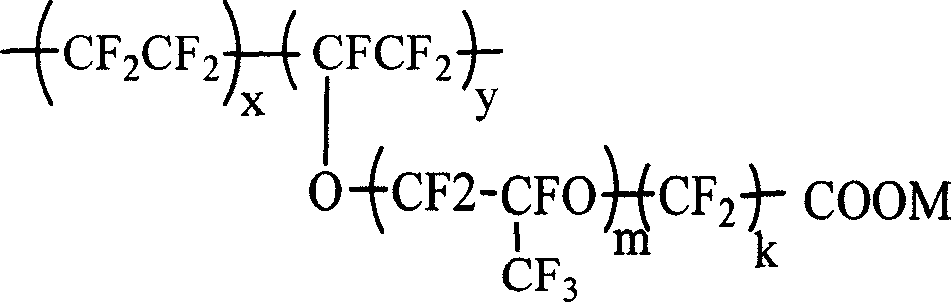

Method used

Image

Examples

Embodiment 1

[0057] The perfluorosulfonic acid resin with the IEC value of 0.95meq / g is converted into the H type and dissolved in N, N-dimethylformamide, then the solution is concentrated to 15%, and the polytetrafluoroethylene biaxially stretched film ( Thickness 50 μm, average pore diameter 1 μm) Boil in methanol for 2 hours and then dry, then dip in the solution obtained above, and dry at 170 ° C for 5 minutes to obtain the first ion exchange layer with a thickness of 55 μm;

[0058] Convert the perfluorosulfonic acid resin with an IEC value of 1.15meq / g into H-type and dissolve it in N,N-dimethylformamide, then concentrate the solution to 30%, and scrape-coat it on the first ion-exchange layer The surface was dried at 170° C. for 10 minutes to obtain a second ion exchange layer with a thickness of 145 μm.

[0059] Convert the perfluorocarboxylic acid resin with an IEC value of 1.25meq / g into H-type and dissolve it in N,N-dimethylformamide, then concentrate the solution to a concentrat...

Embodiment 2

[0062] The perfluorosulfonic acid resin that the IEC value is 0.98meq / g is converted into K type and dissolved in dimethyl sulfoxide, then the solution is concentrated to 20%, and the polytetrafluoroethylene biaxially stretched film (thickness 50 μm, average pore size 2 μm) was boiled in methanol for 2 hours and dried, then immersed in the solution obtained above, and dried at 180° C. for 5 minutes to obtain the first ion exchange layer with a thickness of 60 μm.

[0063] The perfluorocarboxylic acid resin with an IEC value of 1.22meq / g was converted into H-form and dissolved in dimethyl sulfoxide, and then the solution was concentrated to a concentration of 25%.

[0064] Mix the perfluorosulfonic acid resin solution and the perfluorocarboxylic acid resin solution obtained above in a ratio of 50:50, mix the solution evenly and apply it on one side of the film obtained above, and dry it at 180°C for 5 minutes to obtain a thickness The second ion exchange layer is 102μm.

[006...

Embodiment 3

[0068] The perfluorosulfonic acid resin with IEC value of 0.95meq / g is converted into H type and dissolved in propylene glycol, then the solution is concentrated to 16%, and polytetrafluoroethylene biaxially stretched film (thickness 50 μm, average pore size 2 μm) in It was boiled in methanol for 2 hours, dried, then immersed in the solution obtained above, and dried at 200° C. for 4 minutes to obtain the first ion exchange layer with a thickness of 61 μm.

[0069] Convert the perfluorosulfonic acid resin with an IEC value of 1.20meq / g into H-type, dissolve it in ethylene glycol, concentrate the solution to 25%, scrape-coat it on the surface of the first ion-exchange layer, and dry it at 200°C After 3 minutes, the thickness of the second ionic layer was obtained to be 32 μm.

[0070] The copolymerization type perfluorinated ion exchange resin (IEC=0.98meq / g, wherein the quantity ratio of sulfonic acid group and carboxylic acid group is 70:30) containing sulfonic acid group and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com