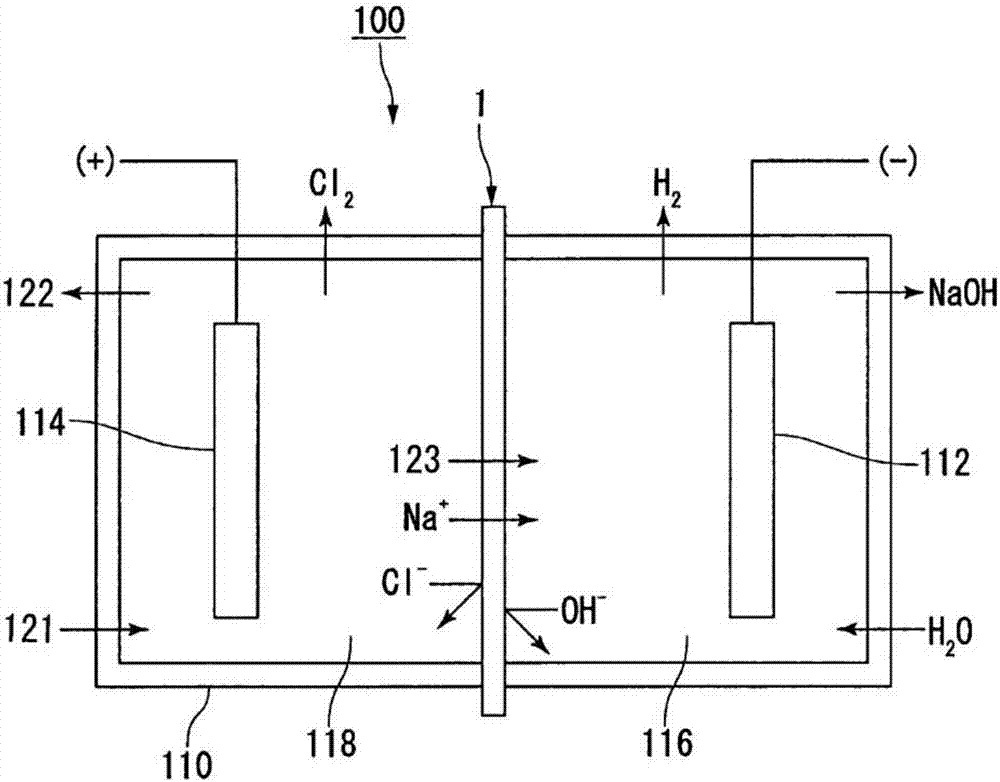

Ion-exchange membrane for alkali chloride electrolysis, manufacturing method, and alkali chloride electrolysis device

A technology of alkali metal chloride and ion exchange membrane, which is applied in the direction of ion exchange treatment devices, ion exchange, cation exchange materials, etc., can solve the problems of electrolysis voltage rise and ion exchange membrane resistance increase, etc., and achieve low electrolysis voltage and increase Effect of low film strength and film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0278] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to the following description. Examples 1-3 are examples, and Examples 4-8 are comparative examples.

[0279] (TQ value)

[0280] The TQ value is a value linked to the molecular weight of the polymer to show the volumetric flow rate: 100mm 3 / sec in the form of temperature. The volumetric flow rate is set as follows: using Shimadzu Flow Tester CFD-100D (manufactured by Shimadzu Corporation), the fluorine-containing polymer having a group capable of being converted into an ion-exchange group is allowed to flow from Outflow when the orifice (diameter: 1mm, length: 1mm) melts and flows out (unit: mm 3 / Second).

[0281] (ion exchange capacity)

[0282] About 0.5 g of fluorine-containing polymer having a group that can be converted into an ion-exchange group is pressed on a flat plate at a temperature about 10°C higher than its TQ value to form a film, and a transmissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com