Paper pulp-capacitance carbon joint production method

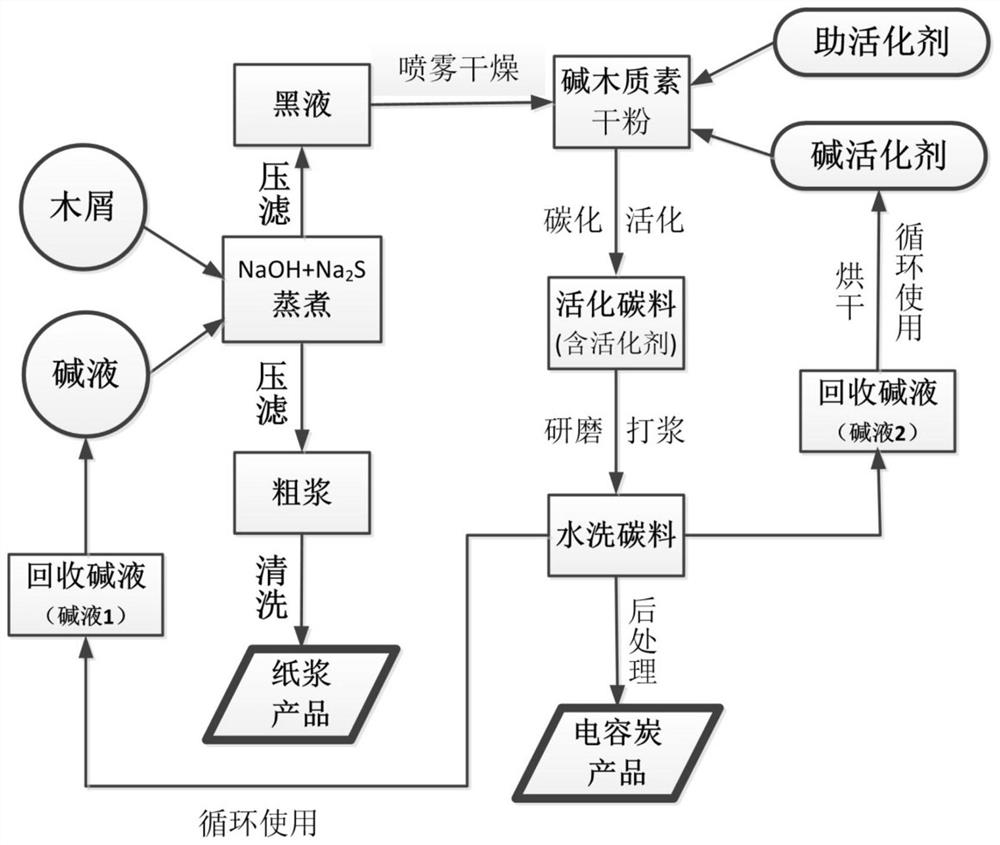

A joint production and capacitive carbon technology, applied in chemical instruments and methods, carbon compounds, pulping with inorganic alkali, etc., can solve the problems of pollution, high cost, waste, etc., and achieve long process, high cost and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The present embodiment directly uses the alkali lignin of Fujian Qingshan Paper Industry, and uses the method of the present invention to burn capacitor charcoal. 2 S) Pulping, using alkali amount a=16%, degree of sulfidation s=20%, solid-to-liquid ratio 1:5, spray-drying the black liquor after concentration to obtain alkali lignin. According to the test, 100 grams of sawdust raw materials can obtain 55 grams of alkali lignin, in which the total alkali (NaOH+Na 2 S) 18.75 grams, lignin and other organic matter 36.25 grams. The present embodiment uses potassium carbonate (K 2 CO 3) is the activator, and urea is the co-activator, illustrating the specific operation steps and results of the paper-carbon cogeneration technology line. Due to the direct use of alkali lignin from paper mills (such as figure 2 Shown) burning capacitor charcoal, has saved step (1) papermaking raw material is boiled in lye and press-filtered to separate cooking liquid, directly enters step (...

Embodiment 2

[0092] Present embodiment takes the Chinese fir chip that Sanming Qingshan Paper Industry Paper Mill provides as raw material, the 76.8 gram mixed total alkali (K) that embodiment 1 reclaims 2 CO 3 , NaOH, Na 2 1 / 5 (15.36 grams) of S) is used for pulping, and NaOH and NaOH are supplemented at a loss rate of 20%. 2 S; the remaining 4 / 5 (61.44 grams) mixed total alkali is used as an activator for burning capacitor carbon, and K is supplemented by a loss rate of 20% 2 CO 3 . The 6 operation steps and results of Example 2 are described below.

[0093] (1) Papermaking raw materials are cooked in lye, separated by pressure filtration and pulp is cleaned

[0094] Sieve off the powder and debris in the sawdust, dry, weigh 100 grams of sawdust and put it in a 2000ml conical flask, add 3.5 grams of NaOH and 1 gram of NaOH to 15.36 grams of recovered mixed alkali 2 S, add deionized water to prepare 500ml solution, pour it into a Erlenmeyer flask, tie the mouth with gauze, and cook ...

Embodiment 3

[0117] A method for joint production of pulp-capacitor carbon, comprising the steps of:

[0118] (1) The bagasse papermaking raw material is pulped by kraft pulping, and separated by pressure filtration to obtain coarse paper pulp and black liquor;

[0119] (2) Coarse pulp is used to prepare pulp products. Put the alkali lignin black liquor on a tray coated with Teflon, dry it in an oven at 120°C until it is dry, and scrape the alkali lignin from the tray Dry glue, put it in a mortar, continue to dry to constant weight, and grind it into dry alkali lignin powder;

[0120] (3) According to the mass ratio of alkali lignin dry powder: alkali activator: co-activator=1:1:0.25, add alkali activator sodium carbonate and co-activator urea in alkali lignin dry powder, finely grind and mix, in relative Aging for 8 hours in a dry environment with a humidity less than 30% to obtain a mixture.

[0121] (4) Put the aged mixture in a silicon carbide crucible, raise the temperature to 880° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com