Method for preparing bagasse dissolving pulp and pre-extracting hemicellulose and product thereof

A technology of hemicellulose and dissolving pulp, which is applied in pulping with inorganic alkali, fiber raw material treatment, chemical instruments and methods, etc., can solve the problem of comprehensive utilization of bagasse, and achieve considerable economic benefits, high extraction rate, comprehensive production The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

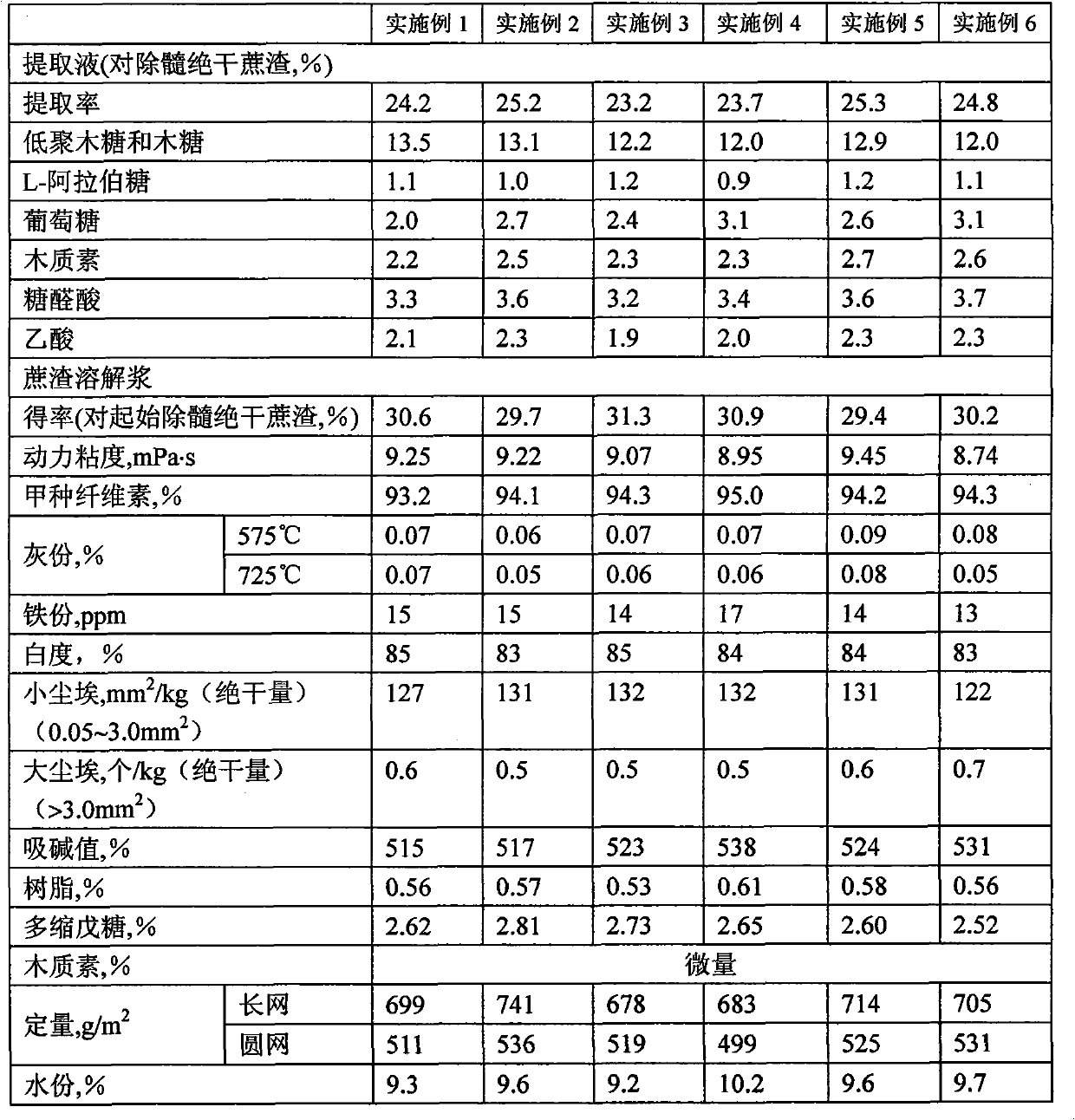

Examples

Embodiment 1

[0041] A kind of bagasse dissolving pulp pulping method of pre-extracting hemicellulose, comprises the following steps:

[0042] (1) Bagasse material preparation: adopt the bagasse that removes most of the colloids through natural storage and fermentation, and carry out wet pitting and washing to the bagasse, and the pitting rate of bagasse is greater than 35%;

[0043] (2) Pre-hydrolysis: carried out in a steaming ball, the process conditions are: to remove the pith and dry bagasse, the solid-liquid ratio is 1:3, the hydrolysis temperature is 150 ° C, the pressure is the saturated steam pressure at the corresponding temperature, and the hydrolysis time is 220 minutes, using steam heating, the pH value of the end point of hydrolysis is 3~4;

[0044] (3) Liquid-solid separation and washing, collecting filtrate to obtain extract: use three-stage screw press to carry out liquid-solid separation and countercurrent washing on the hydrolyzate, the first stage is directly pressed or ...

Embodiment 2

[0061] A kind of bagasse dissolving pulp pulping method of pre-extracting hemicellulose, comprises the following steps:

[0062] (1) bagasse is prepared: with embodiment 1;

[0063] (2) Pre-hydrolysis: carried out in a steaming ball, the process conditions are: for the pulp-removed and dried bagasse, the solid-liquid ratio is 1:3, the temperature is 170°C, the pressure is the saturated steam pressure at the corresponding temperature, and the hydrolysis time is 110°C. Minutes, using steam heating, the pH value of the end point of hydrolysis is 3~4;

[0064] (3) Liquid-solid separation and washing, collecting the filtrate to obtain the extract: same as in Example 1;

[0065] (4) Preparation of dissolving pulp by residual alkali method: same as in Example 1.

Embodiment 3

[0067] A kind of bagasse dissolving pulp pulping method of pre-extracting hemicellulose, comprises the following steps:

[0068] (1) bagasse is prepared: with embodiment 1;

[0069] (2) Pre-hydrolysis: carried out in a steaming ball, the process conditions are: for depitting and dry bagasse, the solid-liquid ratio is 1:6, the temperature is 150°C, the pressure is the saturated steam pressure at the corresponding temperature, and the hydrolysis time is 240°C. Minutes, using steam heating, the pH value of the end point of hydrolysis is 3~4;

[0070] (3) Liquid-solid separation and washing, collecting the filtrate to obtain the extract: same as in Example 1;

[0071] (4) Preparation of dissolving pulp by residue alkali method: comprising the following steps:

[0072] A, cooking: carry out in the steaming ball, the process conditions are: the amount of alkali used is 10-15% (to the initial depitting and absolutely dry bagasse, Na0H), the degree of sulfidation is 15-20%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com