Alkali recovery process for cotton linter soda pulping black liquor

A technology of caustic soda pulping and cotton linters, which is applied in the combustion of pulping waste liquid and other directions, can solve the problems of failing to meet emission standards, complicated procedures, and excessive discharge, and achieves good effects, simple process, and avoidance of re-pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

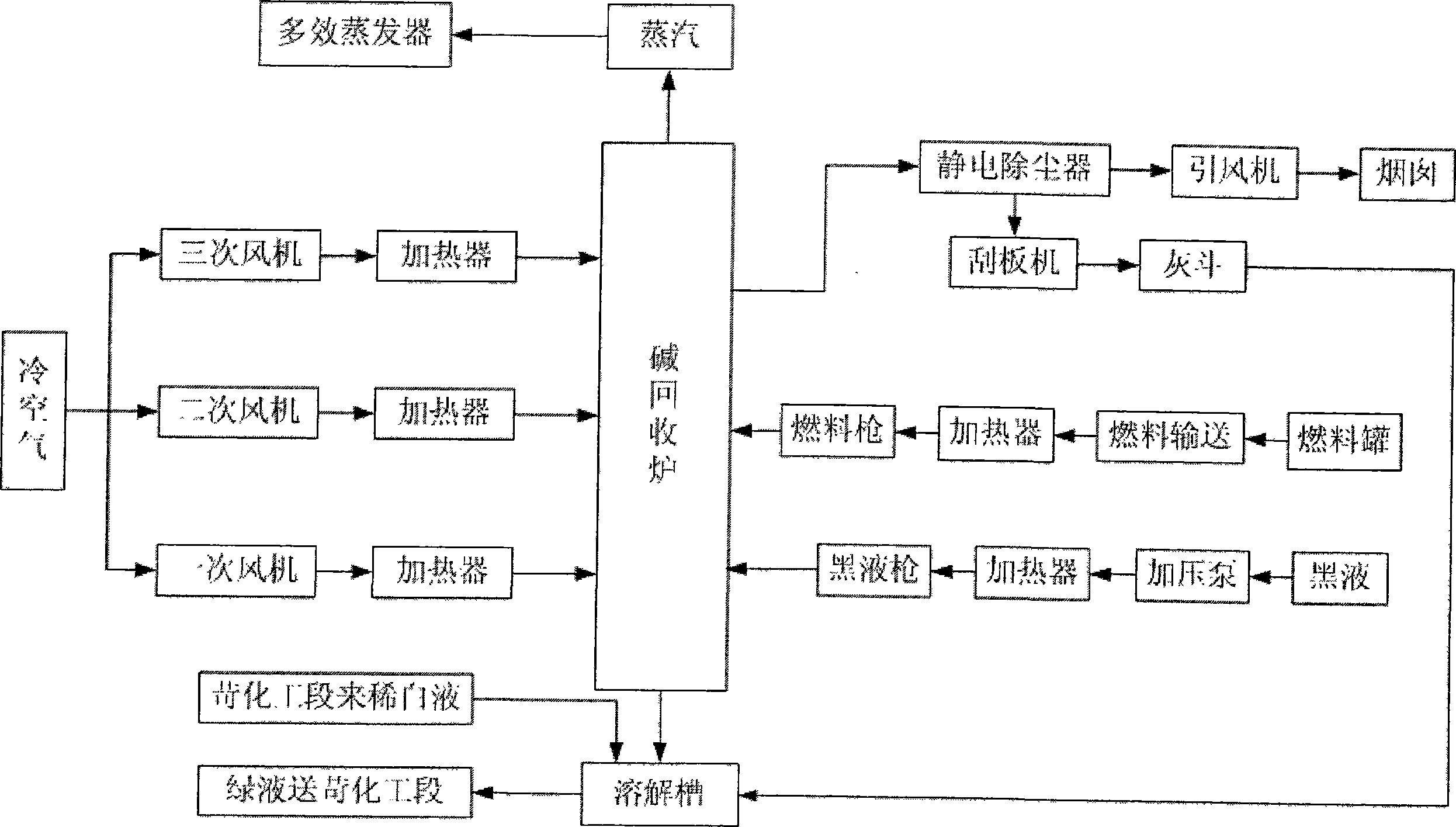

Image

Examples

Embodiment Construction

[0007] The embodiment is described in detail in conjunction with the above process flow chart.

[0008] In the present invention, in the existing alkali recovery process of cotton linter caustic soda pulping, due to the low content of organic matter in the black liquor, it cannot be stably burned in the alkali recovery furnace. Alkali recovery process of conveying cotton pulp black liquor to the furnace. The specific process method is: firstly, the cotton pulp black liquor that has been evaporated and concentrated to a concentration of 40-60% is pressurized to 2.0mpa with a pump, and is atomized and sent into the Combustion in the combustion furnace; during the black liquor combustion, fuel is added to the furnace with auxiliary burners, such as fuel guns and heaters. The fuel can be heavy oil, oxygen or liquefied petroleum gas, etc. Keep the temperature at the bottom of the furnace above 900°C to degrade the organic matter in the black liquor into H at high temperature 2 O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com