Method for preparing bagasse dissolving pulp by improved prehydrolysis alkaline process and product thereof

A technology of dissolving pulp and pre-hydrolysis, applied in the direction of pulping with inorganic alkali, pretreatment with acid compounds, non-woody plant/crop pulp, etc., to achieve the effect of saving resources, reducing production and environmental load, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

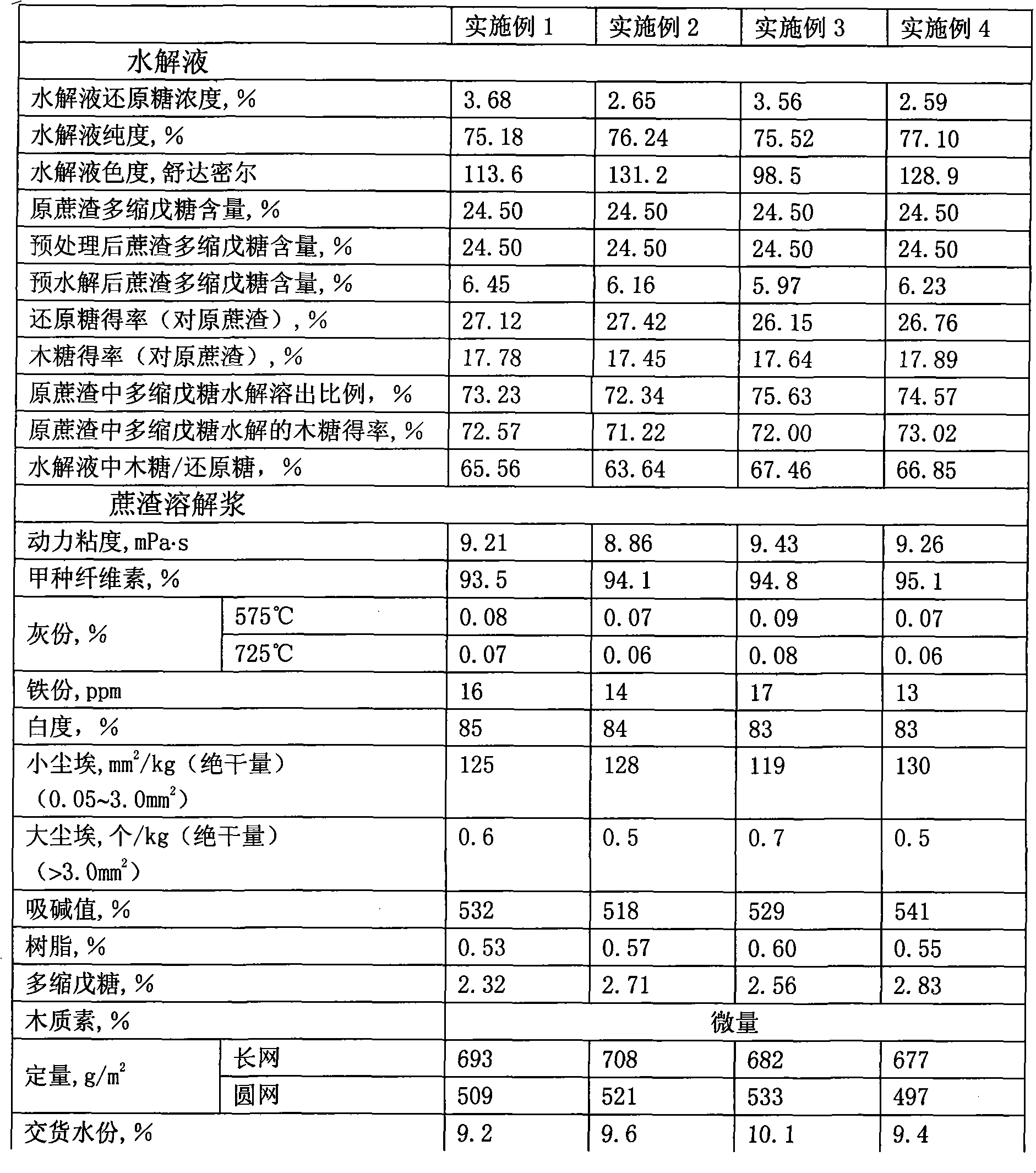

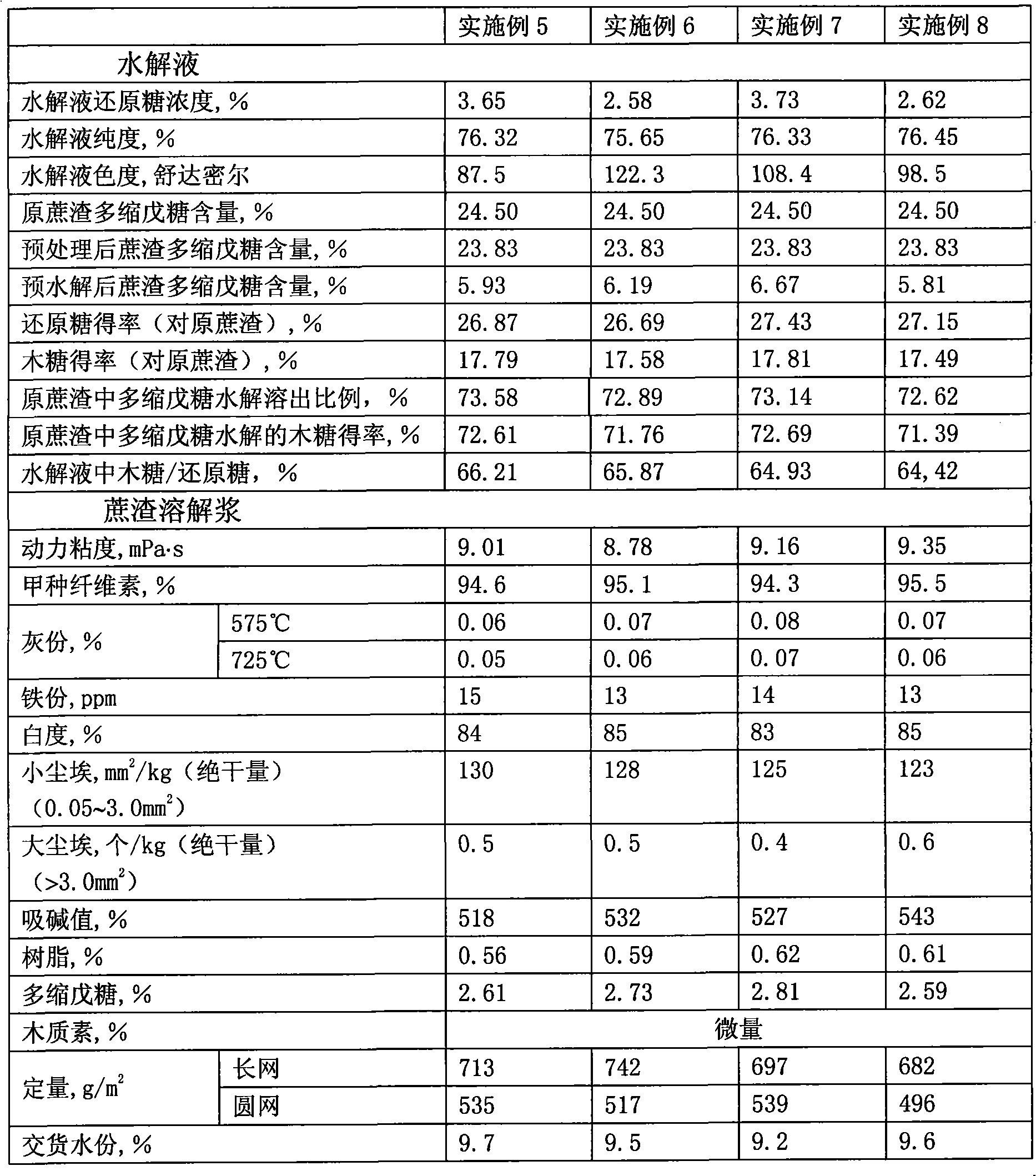

Examples

Embodiment 1

[0060] Provide a kind of method of making bagasse dissolving pulp by improved prehydrolysis alkali method, comprise the steps:

[0061] (1) Bagasse material preparation: adopt the bagasse that removes most of the colloids through natural storage and fermentation, and carry out wet depitting and washing to the bagasse;

[0062] (2) Pre-hydrolysis: carried out in a hydrolysis pot, the hydrolysis catalyst is sulfuric acid, and the process conditions are: the concentration of sulfuric acid is 0.7wt%, the temperature is 110°C, the liquid ratio is 1:7, and the hydrolysis time is 300 minutes. Finally, collect the hydrolyzate and wash the material;

[0063] (3) Alkaline pulping: including the following steps:

[0064] A, cooking: carry out in the digester, the cooking condition is: for absolute dry pulp amount, the total alkali consumption is 18~26% with NaOH, liquid ratio: 1: 2.0~3.6; Heating total time: 150~240 minutes, Small steam release times ≥ 2, the first holding temperature:...

Embodiment 2

[0075] Provide another kind of improved prehydrolysis alkali method to manufacture the method for bagasse dissolving pulp, comprise the steps:

[0076] (1) bagasse material preparation: with embodiment 1, adopt the bagasse that removes most of colloids through natural storage fermentation, and bagasse is carried out wet depitting and washing;

[0077] (2) Pre-hydrolysis: carried out in a hydrolysis pot, the hydrolysis catalyst is sulfuric acid, the process conditions are: the concentration of sulfuric acid is 1.5wt%, the temperature is 125 ° C, the liquid ratio is 1: 10, and the hydrolysis time is 130 minutes. Finally, collect the hydrolyzate and wash the material;

[0078] (3) Alkaline pulping: with embodiment 1.

Embodiment 3

[0080] Another improved prehydrolysis alkali method is provided to manufacture bagasse dissolving pulp, comprising the steps of:

[0081] (1) bagasse material preparation: with embodiment 1, adopt the bagasse that removes most of colloids through natural storage fermentation, and bagasse is carried out wet depitting and washing;

[0082] (2) pre-hydrolysis: with embodiment 1, carry out in hydrolysis pot, treatment agent is sulfuric acid, and processing condition is: sulfuric acid concentration is 0.7wt%, and temperature is 110 ℃, and liquid ratio is 1: 7, and hydrolysis time is 300 minutes, Use steam to heat, collect the hydrolyzate after hydrolysis, and wash the material;

[0083] (3) Alkaline pulping: including the following steps:

[0084]A. Cooking: Carried out in a digester, the cooking conditions are: for the absolute dry pulp, the total alkali dosage is 18-26% in terms of NaOH, the degree of sulfidation: 15-25%, the liquid ratio: 1: 2.0-3.6; Total time: 150-240 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com