Gas-liquid two-phase sulfonated alkaline pulping waste lye to prepare coal-water slurry additive

A technology of waste lye and sulfonated alkali is applied in the field of resource utilization and environmental protection, which can solve the problems of waste of resources and pollute the environment, and achieve the effect of improving product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

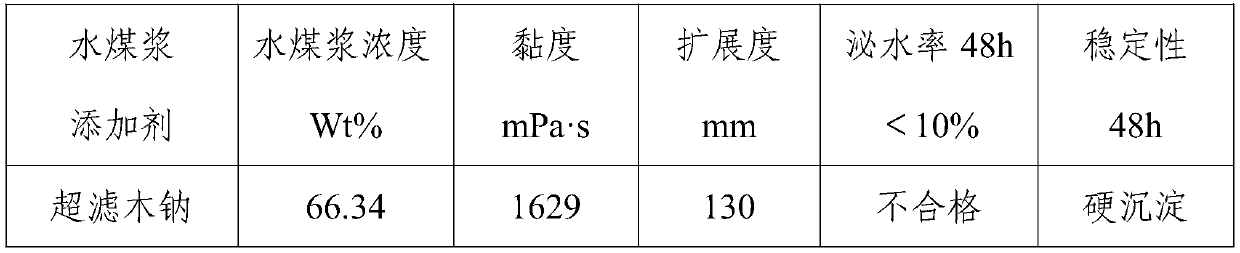

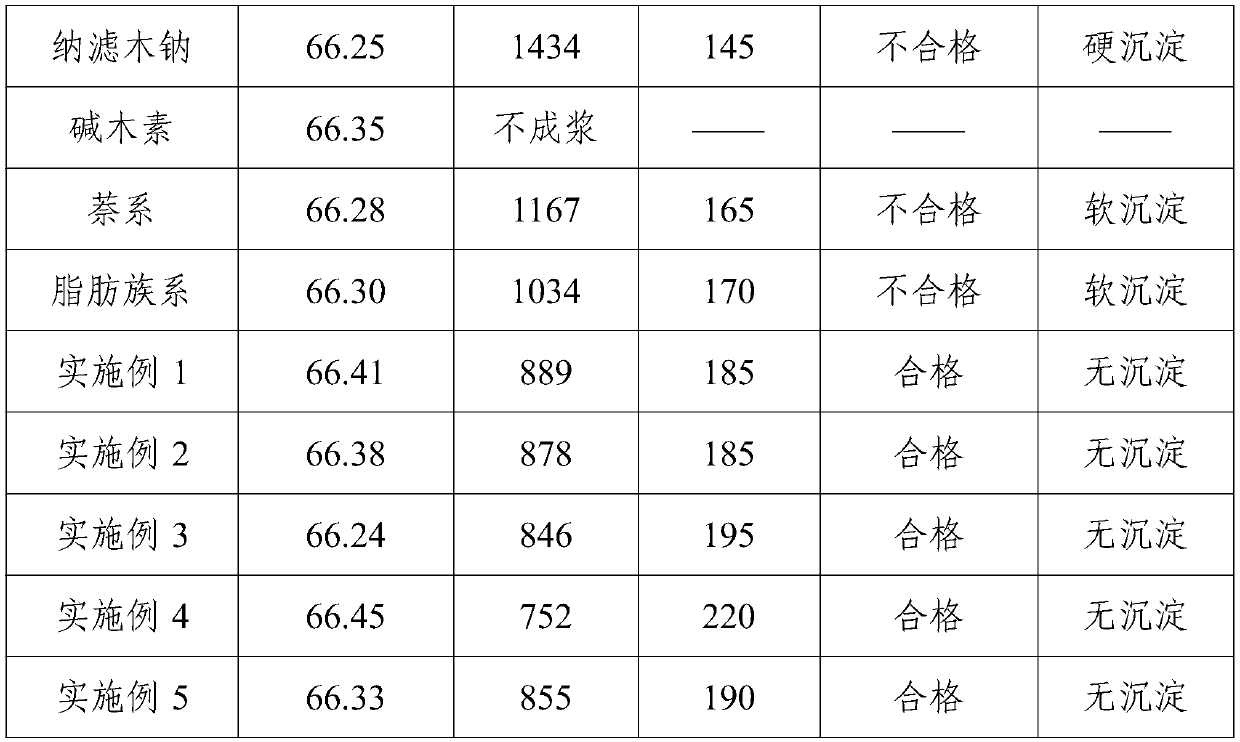

Examples

Embodiment 1

[0024] A gas-liquid two-phase sulfonated alkali pulping waste lye additive for preparing coal-water slurry, which is made of the following raw materials in parts by weight: 85 parts of waste lye, 40 parts of sulfur dioxide, 66 parts of phenolic waste water, and 6.5 parts of hydrogen peroxide Parts, 45 parts of formaldehyde, 10 parts of liquid caustic soda.

[0025] The above gas-liquid two-phase sulfonated alkali pulping waste caustic liquor preparation method for preparing coal-water slurry additives comprises the following steps:

[0026] (1) Add spent lye to the reaction kettle, heat to 55°C, and slowly feed sulfur dioxide while stirring for 25 minutes until the feeding is completed;

[0027] (2) Add phenolic waste water and hydrogen peroxide to the reactor, raise the temperature to 75°C, keep warm for 1.5h, continue to add formaldehyde dropwise to the reactor for 25min, after the dropwise addition, keep warm for 2.5h, and use liquid caustic soda Adjust the pH to 10 to obt...

Embodiment 2

[0029] A gas-liquid two-phase sulfonated alkali pulping waste lye additive for preparing coal-water slurry, which is made of the following raw materials in parts by weight: 80 parts of waste lye, 45 parts of sulfur dioxide, 85 parts of phenolic waste water, and 8.0 parts of hydrogen peroxide Parts, 26 parts of formaldehyde, 12 parts of liquid caustic soda.

[0030] The above gas-liquid two-phase sulfonated alkali pulping waste caustic liquor preparation method for preparing coal-water slurry additives comprises the following steps:

[0031] (1) Add the spent lye to the reaction kettle, heat to 50°C, and slowly feed in sulfur dioxide while stirring, and the feeding time is 20 minutes until the feeding is completed;

[0032] (2) Add phenolic waste water and hydrogen peroxide to the reactor, raise the temperature to 70°C, keep it warm for 1 hour, continue to add formaldehyde dropwise to the reactor for 20 minutes, after the dropwise addition, keep it warm for 2 hours, and adjust ...

Embodiment 3

[0034] A gas-liquid two-phase sulfonated alkali pulping waste lye additive for preparing coal-water slurry, which is made of the following raw materials in parts by weight: 85 parts of waste lye, 35 parts of sulfur dioxide, 80 parts of phenolic waste water, and 7.5 parts of hydrogen peroxide Parts, 34 parts of formaldehyde, 15 parts of liquid caustic soda.

[0035] The above gas-liquid two-phase sulfonated alkali pulping waste caustic liquor preparation method for preparing coal-water slurry additives comprises the following steps:

[0036] (1) Add spent lye to the reaction kettle, heat to 60°C, and slowly feed sulfur dioxide while stirring for 30 minutes until the feeding is completed;

[0037] (2) Add phenolic waste water and hydrogen peroxide to the reactor, raise the temperature to 80°C, keep it warm for 2 hours, continue to add formaldehyde dropwise to the reactor for 30 minutes, after the dropwise addition, keep it warm for 3 hours, and adjust the pH with liquid alkali ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com