Method for producing zirconia denture through rapid prototype of gel-casting

A technology of gel injection molding and zirconia, which is applied in medical science, dentistry, dental prosthesis, etc., can solve the problems of high processing cost, low manufacturing efficiency, and large material waste, and achieve low manufacturing cost, high manufacturing efficiency, The effect of high green body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

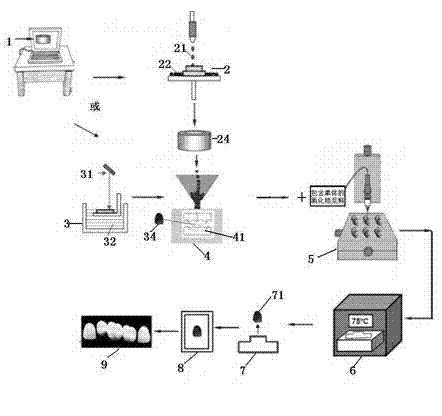

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the method provided by the present invention for preparing dentures by gel-casting zirconia rapid prototyping comprises the following steps:

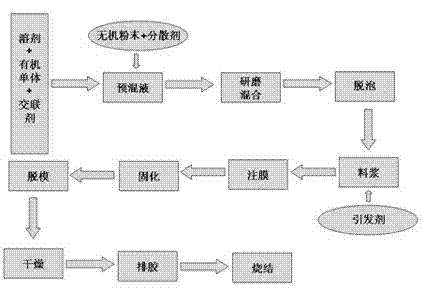

[0025] Step 1, collect the 3D data of the oral cavity through the computer, and generate the 3D CAD virtual model 1 of the required denture; Step 2, prepare the male model of the required denture according to the 3D CAD virtual model 1 of Step 1; Prepare the female mold 41 of the required denture from the positive mold; step 4, perform injection 5 through the gel injection molding process, that is, inject the colloidal slurry containing zirconia into the female mold 41 of step 3, and then add triggering agent and heat to induce polymerization reaction 6, so that the colloidal slurry containing zirconia is solidified; step 5, the cured zirconia is demolded and dried 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com