Method for culturing oyster mushroom

A technology for oyster mushrooms and strains, which is applied in the fields of botanical equipment and methods, horticulture, and applications, can solve the problems of decreased yield, insufficient nutrient content and species, and low biotransformation rate of oyster mushrooms, so as to increase yield and alleviate problems. Harm to the environment, the effect of improving the biotransformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

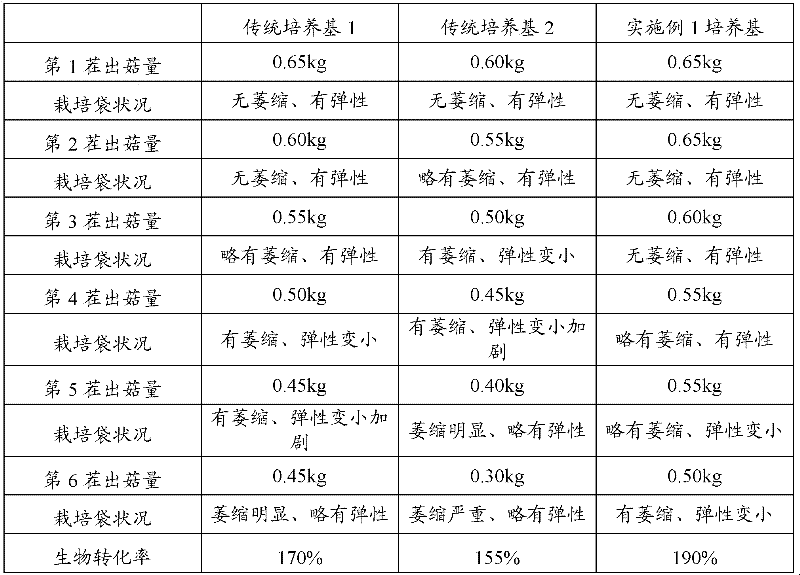

[0021] Embodiment 1: the method for cultivating flat mushroom of the present invention

[0022] The medium waste for cultivating fungus is taken from a local cultivating fungus enterprise, remove the outer plastic bag, expose it to the sun for 5-7 days, and then beat it evenly to the size of corn kernels;

[0023] In terms of mass percentage, weigh 75% culture medium waste of fungus cultivation, 14% rice husk, 9% corn flour, 1% lime and 1% carbendazim, add water and mix thoroughly, and the mass ratio of material to water is between 1:1.3 Between -1.4, adjust the pH value between 6.5-7.5, select a high-density polyethylene film tube with a width of 20-22cm, a length of 45-50cm, and a thickness of 0.02-0.025mm for bagging. Sterilize the bagged medium at high temperature, the sterilization temperature is 100°C, the sterilization time is 12 hours after the air is applied, and the inoculation operation is carried out after the temperature of the bag drops below 25°C. High-quality ...

Embodiment 2

[0026] Embodiment 2: the method for cultivating flat mushroom of the present invention

[0027] The medium waste for cultivating fungus is taken from a local cultivating fungus enterprise, remove the outer plastic bag, expose it to the sun for 5-7 days, and then beat it evenly to the size of corn kernels;

[0028] In terms of mass percentage, weigh 80% culture medium waste of fungus cultivation, 12% rice husk, 7% corn flour, 0.5% lime and 0.5% carbendazim, add water and mix thoroughly, and the mass ratio of material to water is between 1:1.3 Between -1.4, adjust the pH value between 6.5-7.5, select a high-density polyethylene film tube with a width of 20-22cm, a length of 45-50cm, and a thickness of 0.02-0.025mm for bagging. Sterilize the bagged medium at high temperature, the sterilization temperature is 100°C, the sterilization time is 12 hours after the air is applied, and the inoculation operation is carried out after the temperature of the bag drops below 25°C. High-qual...

Embodiment 3

[0031] Embodiment 3: the method for cultivating flat mushroom of the present invention

[0032] The medium waste for cultivating fungus is taken from a local cultivating fungus enterprise, remove the outer plastic bag, expose it to the sun for 5-7 days, and then beat it evenly to the size of corn kernels;

[0033]In terms of mass percentage, weigh 71% of culture medium waste for cultivating fungus, 16% of rice husk, 11% of corn flour, 1% of lime and 1% of carbendazim, add water and mix thoroughly, and the mass ratio of material to water is between 1:1.3 Between -1.4, adjust the pH value between 6.5-7.5, select a high-density polyethylene film tube with a width of 20-22cm, a length of 45-50cm, and a thickness of 0.02-0.025mm for bagging. Sterilize the bagged medium at high temperature, the sterilization temperature is 100°C, the sterilization time is 12 hours after the air is applied, and the inoculation operation is carried out after the temperature of the bag drops below 25°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com