Building prefabricated wall and production technology

A prefabricated assembly and production process technology, applied in construction, manufacturing tools, building types, etc., can solve problems such as inability to recycle, cannot meet shading at the same time, cumbersome on-site workload, etc., to achieve uncomplicated production process and combination The structure is simple and reliable, and the effect of improving the installation speed and construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, objectives, and effects of the invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

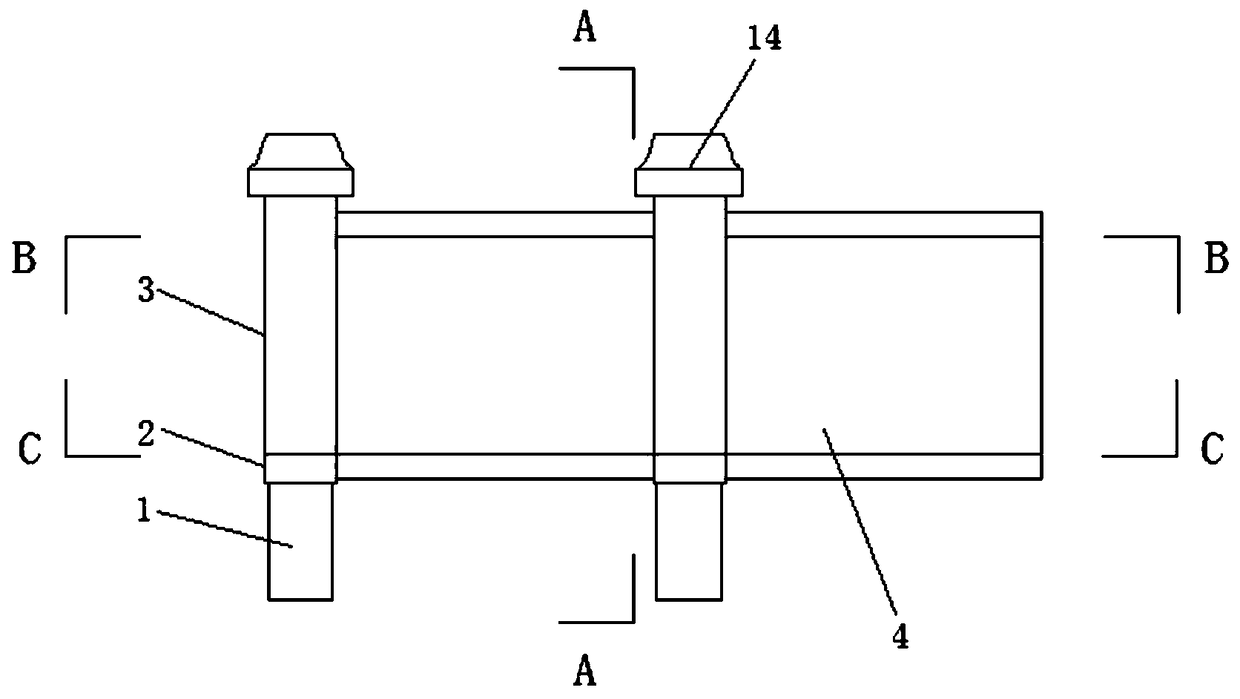

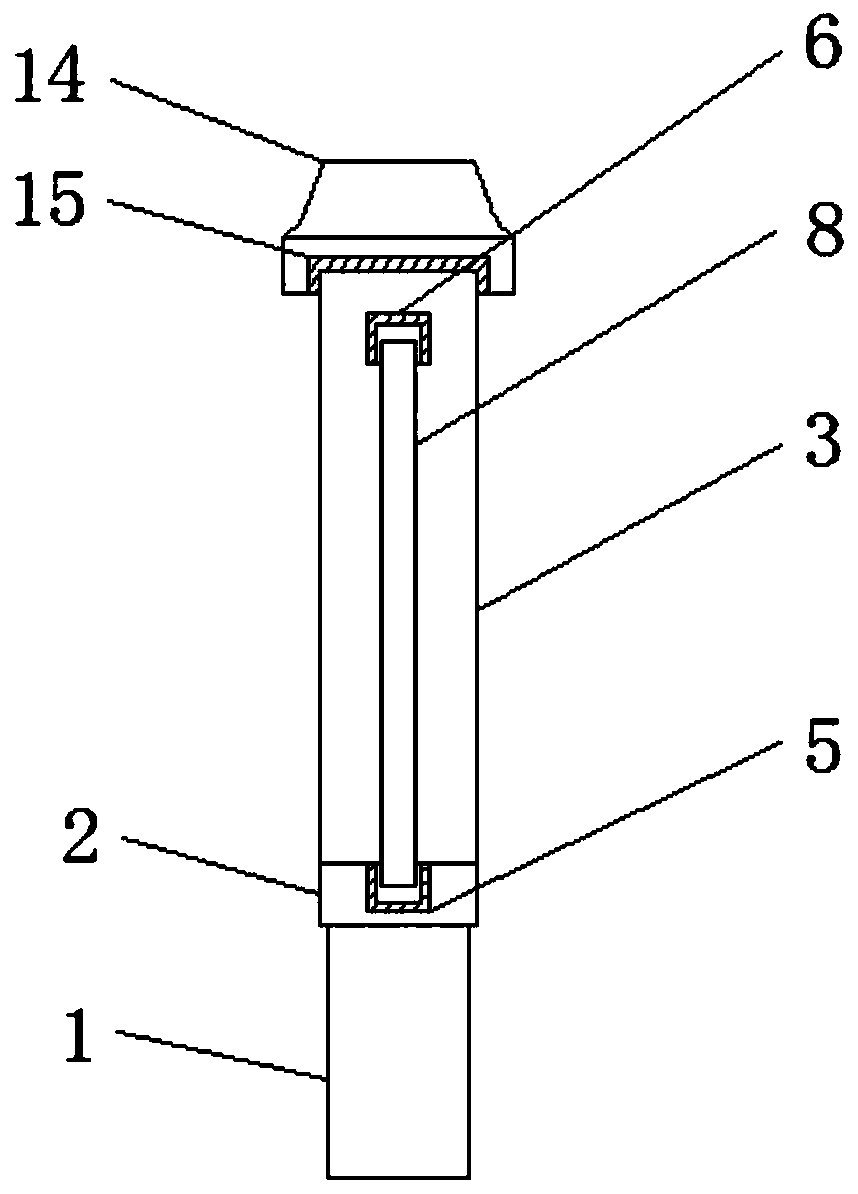

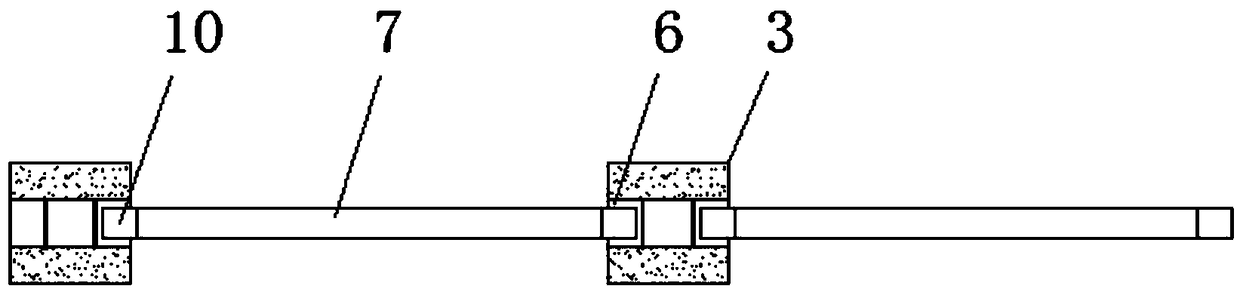

[0032] A building prefabricated enclosure, including a base column 1 and a connecting plate 2 arranged on the top of the base column 1, above the connecting plate 2 is provided with a wind-resistant column 3 through fixing bolts, adjacent to the wind-resistant column 3 A combined wall 4 is arranged between them, positioning vertical grooves 5 are arranged above both sides of the connecting plate 2, and insertion vertical grooves 6 are arranged above both sides of the wind-resistant column 3, and the combined wall 4 includes a positioning Upper plate 7, wall plate 8 and positioning lower plate 9, adjacent to the vertical slot 6 is provided with a positioning upper plate 7, the bottom of the positioning upper plate 7 is provided with a wall plate 8, the wall plate 8 The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com