Oil-containing waste water processing and recycling method

A waste water and biochemical treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc., can solve problems such as waste water treatment system paralysis, affecting normal production of enterprises, and long system recovery period , to improve the treatment effect and impact resistance, ensure normal and stable operation, and stabilize the quality of biochemical influent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

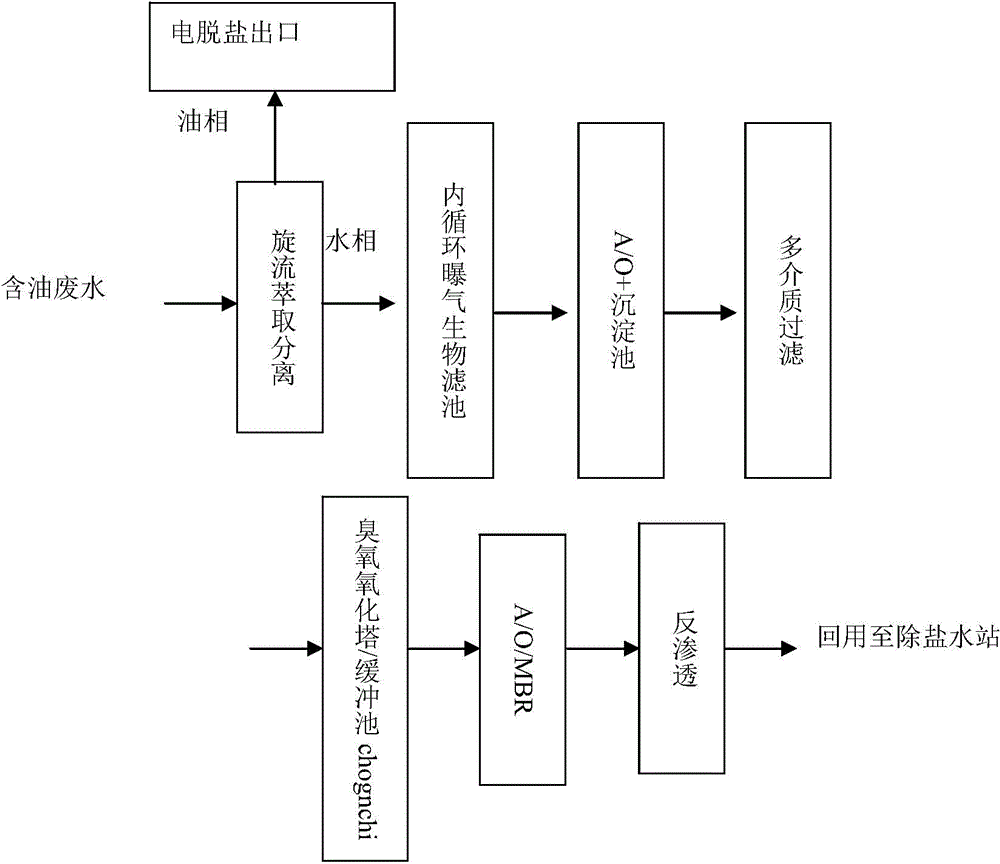

Image

Examples

Embodiment 1、2、3

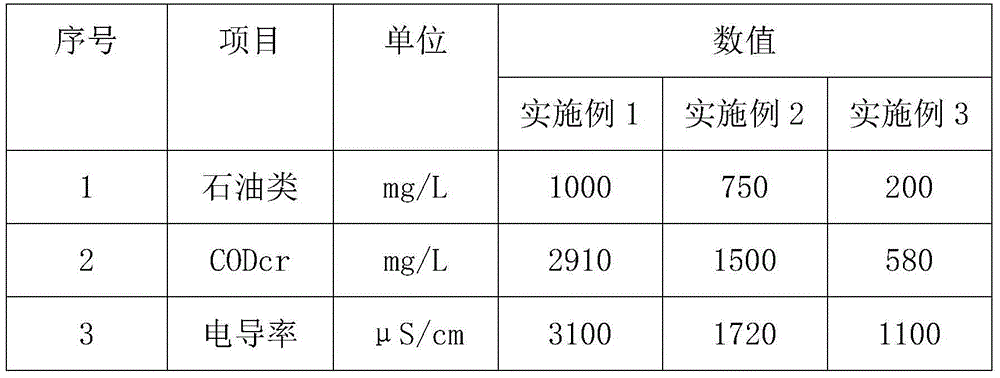

[0091] See Table 1 for the water quality of oily wastewater from a refinery

[0092] Table 1 Water quality of oily wastewater

[0093]

[0094] Adopt the method of the present invention:

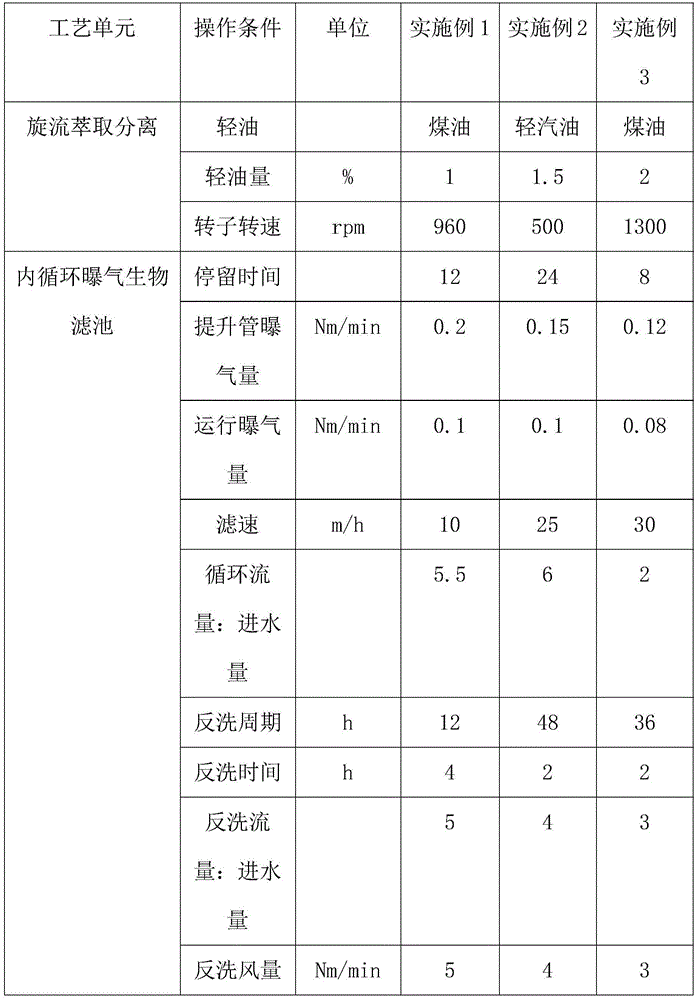

[0095] (1) The oily wastewater is pressurized into the cyclone extraction separator through the pump, and at the same time, the light oil of 0.5-5% of the treated oily wastewater is injected into the cyclone extraction separator according to the mass percentage,

[0096] Through the high-speed rotation separation of the cyclone extraction separator, the high-efficiency separation of oil and water is realized, and the oil concentration in the separated water phase is less than 100mg / L;

[0097] (2) The aqueous phase separated by cyclone extraction is filtered through the internal circulation biological aerated filter, and most of the oil and organic matter in the wastewater are further removed;

[0098] (3) The effluent of the internal circulation biological aerated filter directly enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com