Process for recovering iron and rare earth in baotite low-intensity magnetic separation tailings

A weak magnetic separation, Baotou ore technology, applied in flotation, magnetic separation, chemical instruments and methods, etc., can solve the problems of unrecovered and difficult secondary recovery of iron minerals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with specific examples.

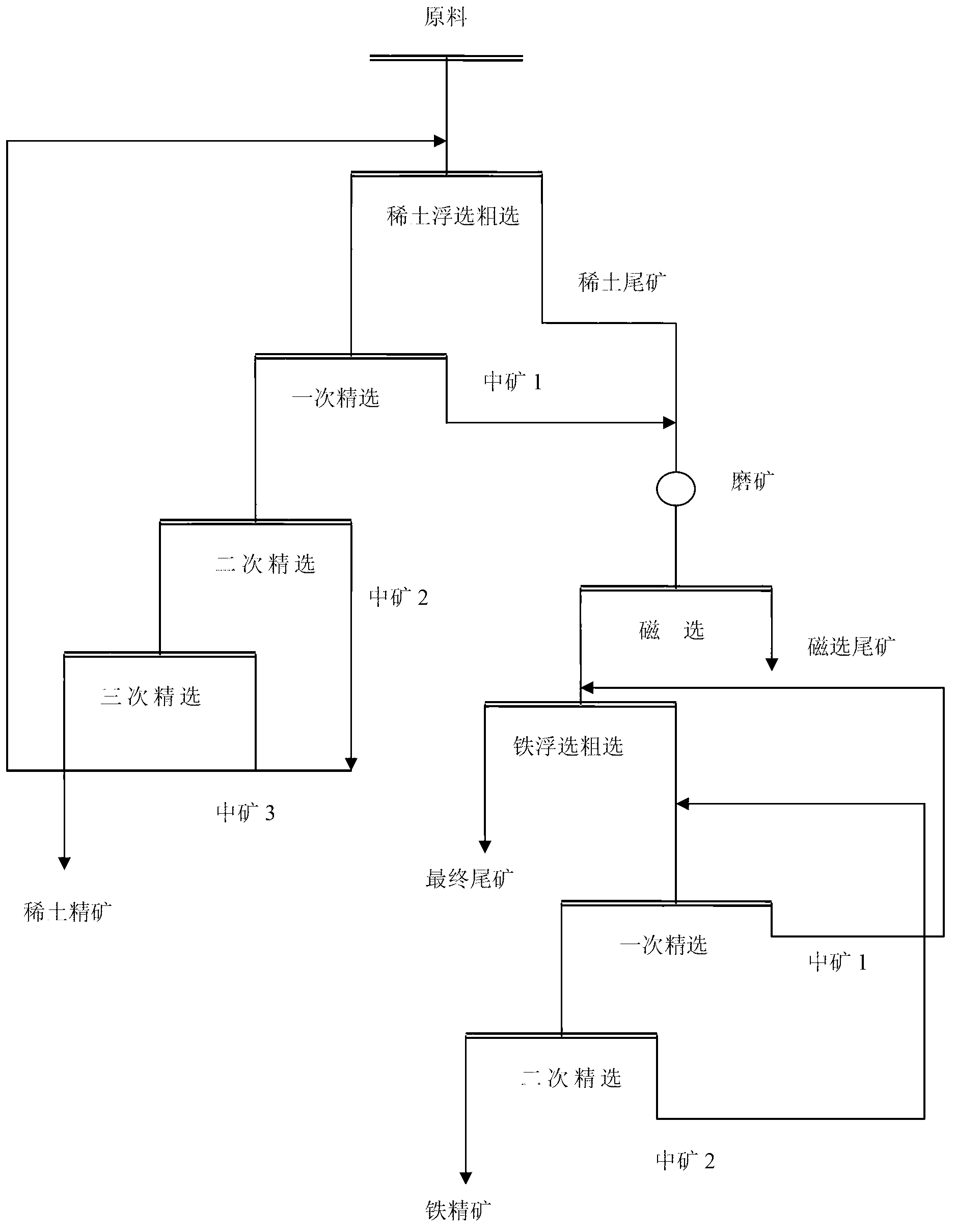

[0014] A recovery process for iron and rare earths in weak magnetic separation tailings of Baotou Mine, which mainly includes the following parts:

[0015] 1. The weak magnetic separation tailings in the current process are naturally dried, crushed and mixed evenly.

[0016] 2. Use the above raw materials as raw materials for rare earth flotation. First, control the temperature of the pulp at 44-46°C, then add 5.0kg / t of water glass, adjust the pH value to 9-9.5, and then add salicylhydroxime at a mass ratio of 7.5:1 Acid and alkylhydroxamic acid compound collector 3.5kg / t, under the better flotation conditions, rare earth rough separation is carried out to obtain rare earth rough concentrate and rare earth tailings; adjust the slurry temperature of rare earth rough concentrate to 44-46°C, then add water glass 1.1kg / t, adjust the pH value to 9-9.5, and then add 0.7kg / t compound collector of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com