Integrated solid waste treatment system and use method thereof

A technology of treatment system and power system, applied in the field of integrated solid waste treatment system, can solve the problems of insufficient solid waste treatment and disposal facilities, low heat recovery efficiency, and difficult separation and treatment, so as to ensure the quality of solid waste treatment and reduce the amount of waste. The effect of chemical treatment is remarkable, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

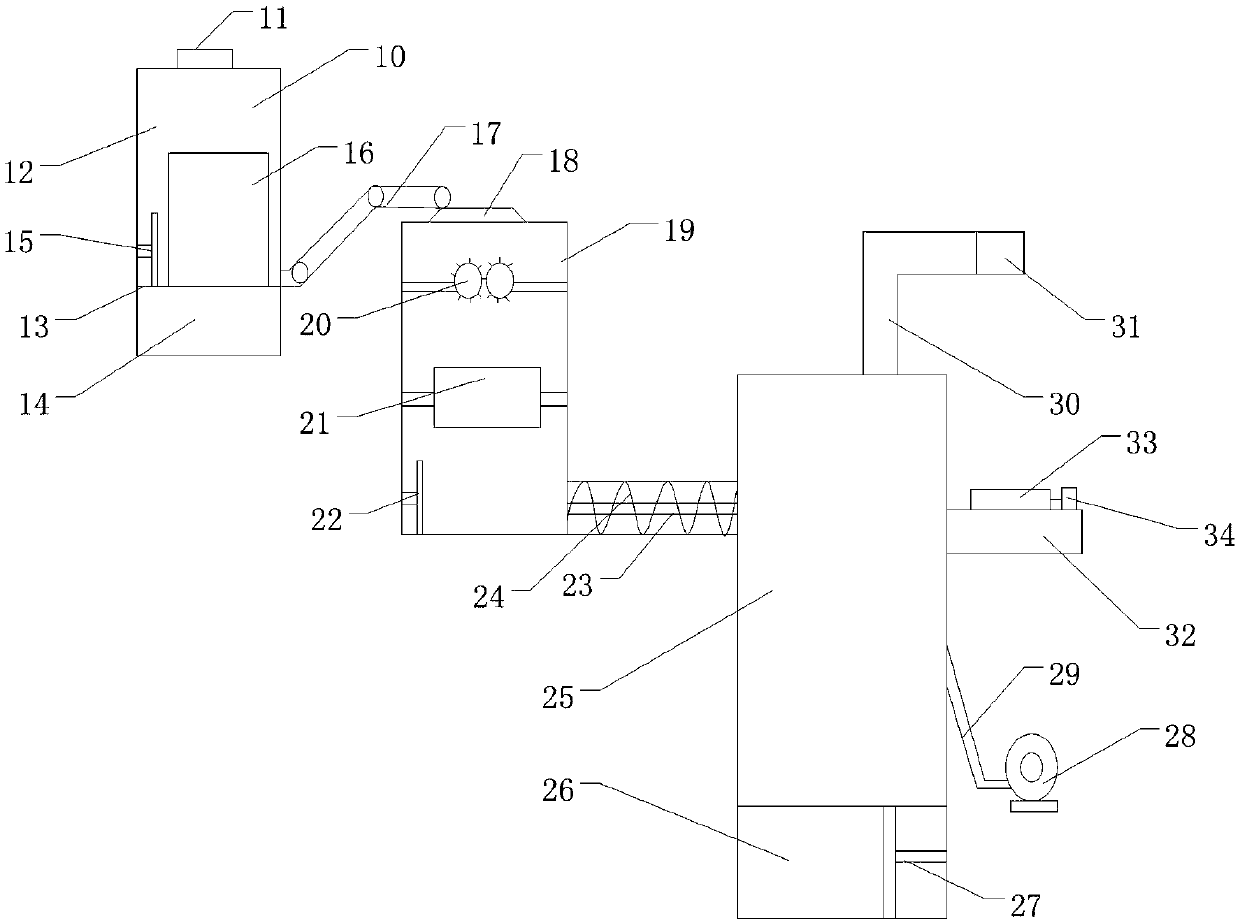

[0063] 1. Put the solid-liquid mixed waste into the first box 10 through the first inlet 11 of the first box 10, the solid-liquid waste falls on the filter screen 13, and the first gravity sensor senses the gravity of the waste The signal is transmitted to the first power system and the second power system, the first power system drives the extruding device 16 to squeeze the waste 2-3 times, and the first pushing device 15 pushes the waste to the conveyor belt 17; The power system drives the conveyor belt 17, the shearing crusher 20 and the magnetic drum 21 to start rotating.

[0064] 2. The conveyor belt transports the waste to the second box 19, and the shearing crusher 20 crushes the waste. The crushed waste is dropped by the shearing crusher 20, and the metal substances in the waste are crushed. The magnetic roller 21 absorbs, and the non-metallic substance falls to the bottom of the second box 19 .

[0065] 3. After the second gravity sensor senses the gravity of the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com