Efficient and energy-saving type biological fermentation tank and matched pipe network system thereof

A technology of biological fermenter and supporting pipe, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-processing, etc., can solve the problem of long distribution distance of control valve and low oxygen utilization rate , low production efficiency and other problems, to achieve the effect of optimizing quality, scientific pipe network layout, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

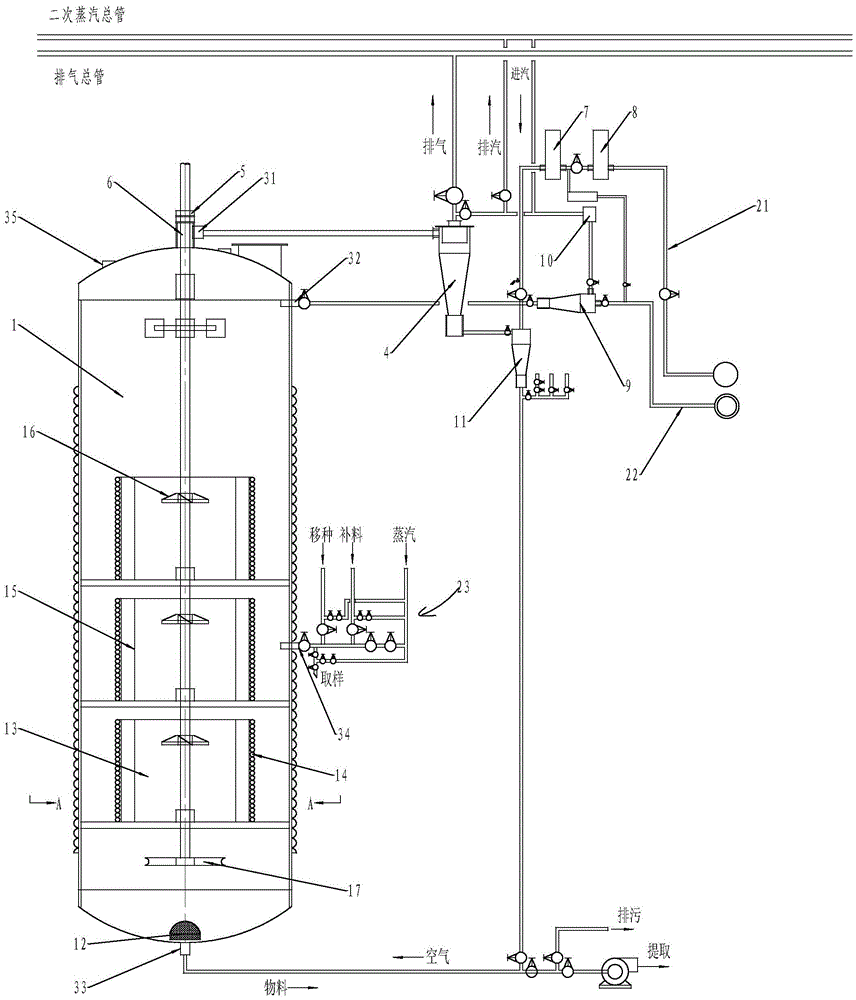

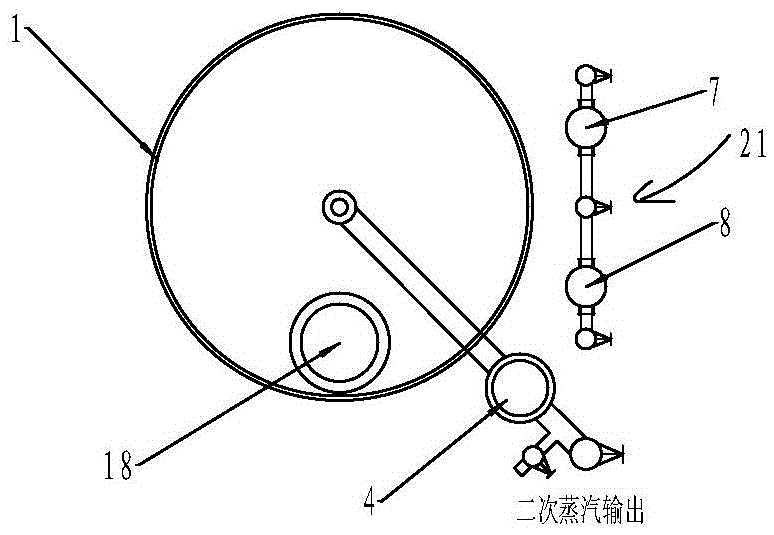

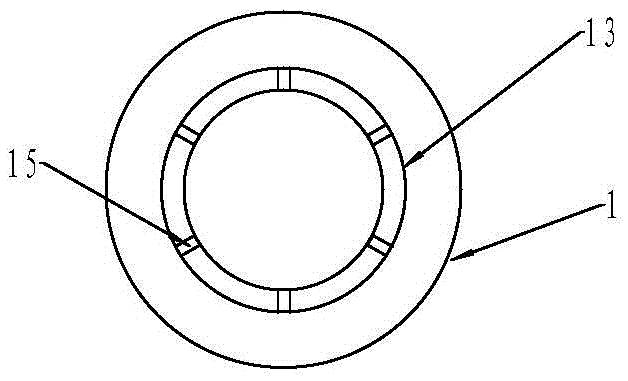

[0031] Such as figure 1 The new high-efficiency and energy-saving biological fermentation tank with its supporting pipe network system includes a biological fermentation tank 1 and a process pipe network composed of an air pipe network system 21 connected to the tank body, a sterile material pipe network system 23, and a steam pipe network system 22 . A central exhaust pipe port 31 is opened in the center of the top of the tank. The central exhaust pipe port 31 is connected to the cyclone separator collector 4 to collect and recover the escaped. A set of three-way pipe fittings 6 is added to the cyclone separator collector 4 under the mechanical sealer 5. The pressure material air nozzle 32 is located on the upper side of the tank. The air main pipe is equipped with an air pre-filter 8, a fine filter 7, and a secondary steam mixer 9; the steam main pipe is equipped with a secondary steam recovery booster pump 10 and a The secondary air mixer 11; the inlet air outlet material no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com