System and method for recovering waste heat of coke-oven crude gas

A waste heat recovery system and waste gas technology, which are applied in the steam generation method using heat carrier and other directions, can solve problems such as water leakage of the riser water jacket, difficulty in opening the cover of the riser, waste heat recovery of waste gas, etc., and achieve the recovery calorific value The effect of sufficient, strong promotion value and high heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

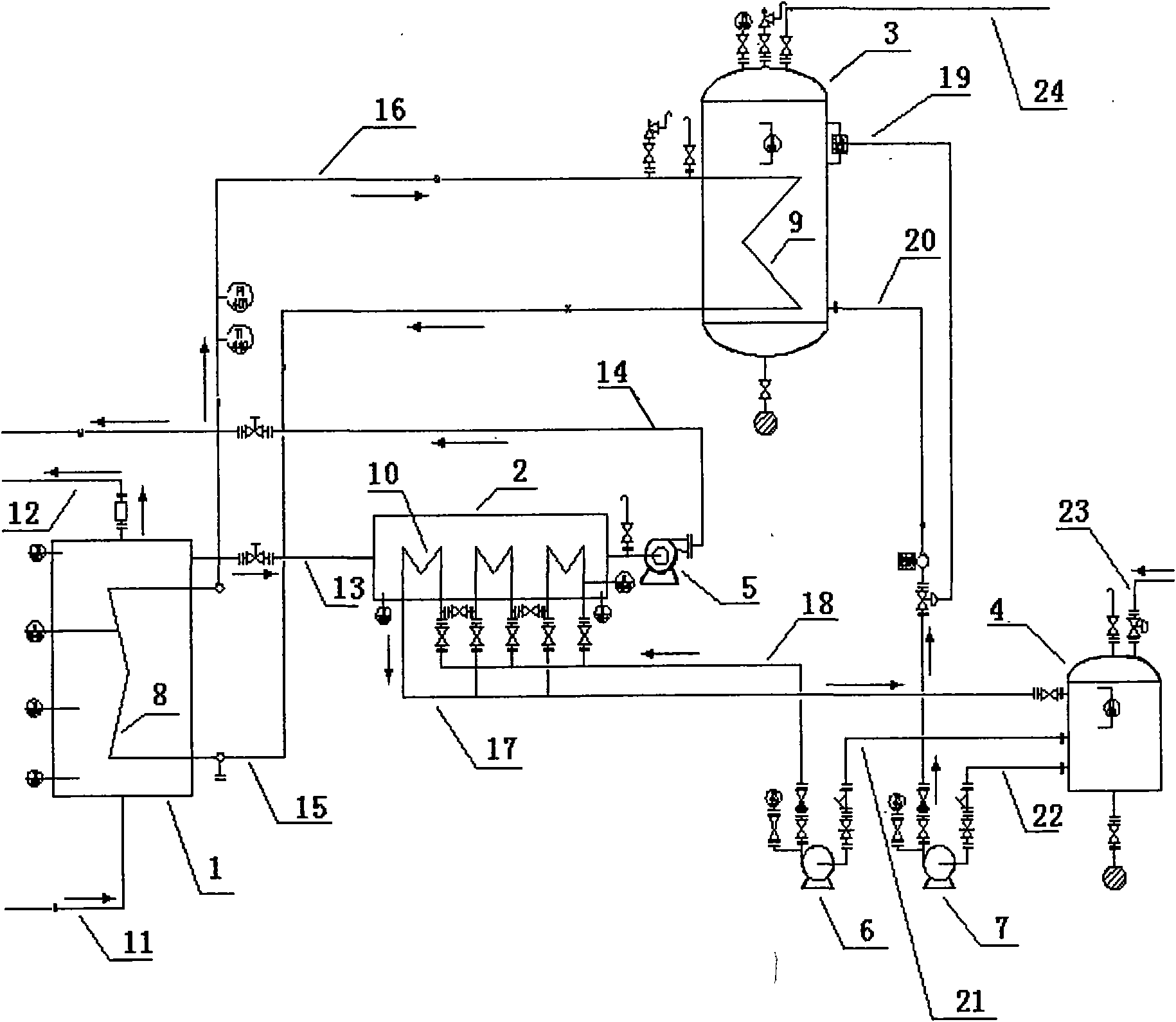

[0018] refer to figure 1 , Coke oven raw gas waste heat recovery system, mainly composed of high-end heat energy (800 ℃ ~ 500 ℃) low-end heat energy (500 ℃ ~ 280 ℃) secondary absorption device and water supply system. The structure of the recovery system is connected to the water storage tank 4 by the water pipe 23, which is used as a supplementary fresh water channel entering the system from the outside, and then through the water storage tank 4, the water supply pipe I 22 and the water supply pipe II 21 are respectively connected to the high-end and low-end secondary heat-absorbing devices Perform heat exchange, and finally the steam generated in the steam drum 3 is exported through the steam output pipe 24 .

[0019] The high-end heat energy absorption device is mainly composed of a riser pipe and a separate heat pipe 8 fixed on the inner wall of the raw gas waste heat recovery device 1, which is connected to the heat release end heat pipe 9 in the steam drum 3 through a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com