Dust removal equipment for melting furnace

A technology for dust removal equipment and furnaces, applied in lighting and heating equipment, furnaces, charge materials, etc., can solve the problems of wasting energy, polluting the environment, and insufficient recycling of steel slag, and achieve the effect of avoiding safety accidents and preventing sparks from being ejected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

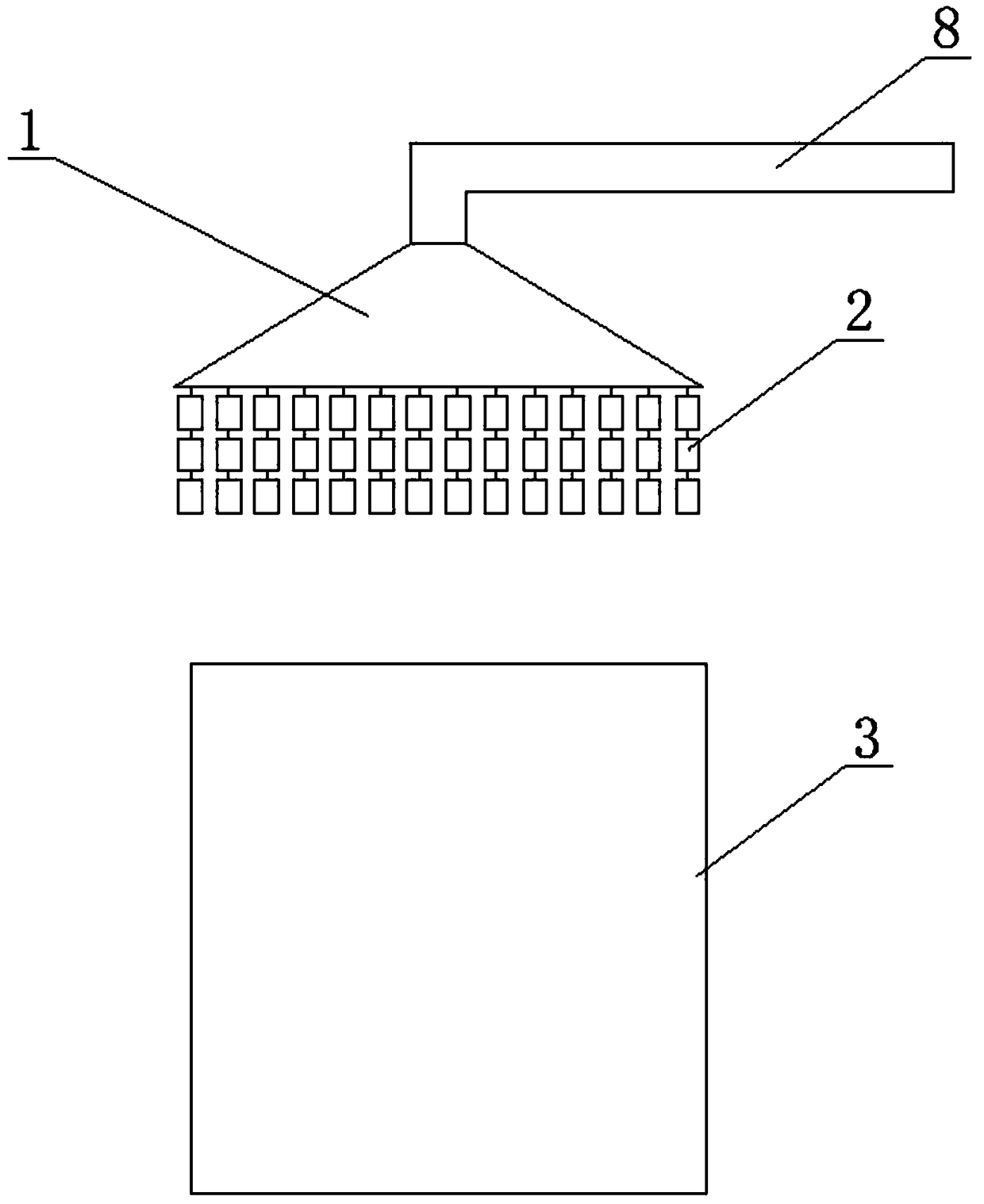

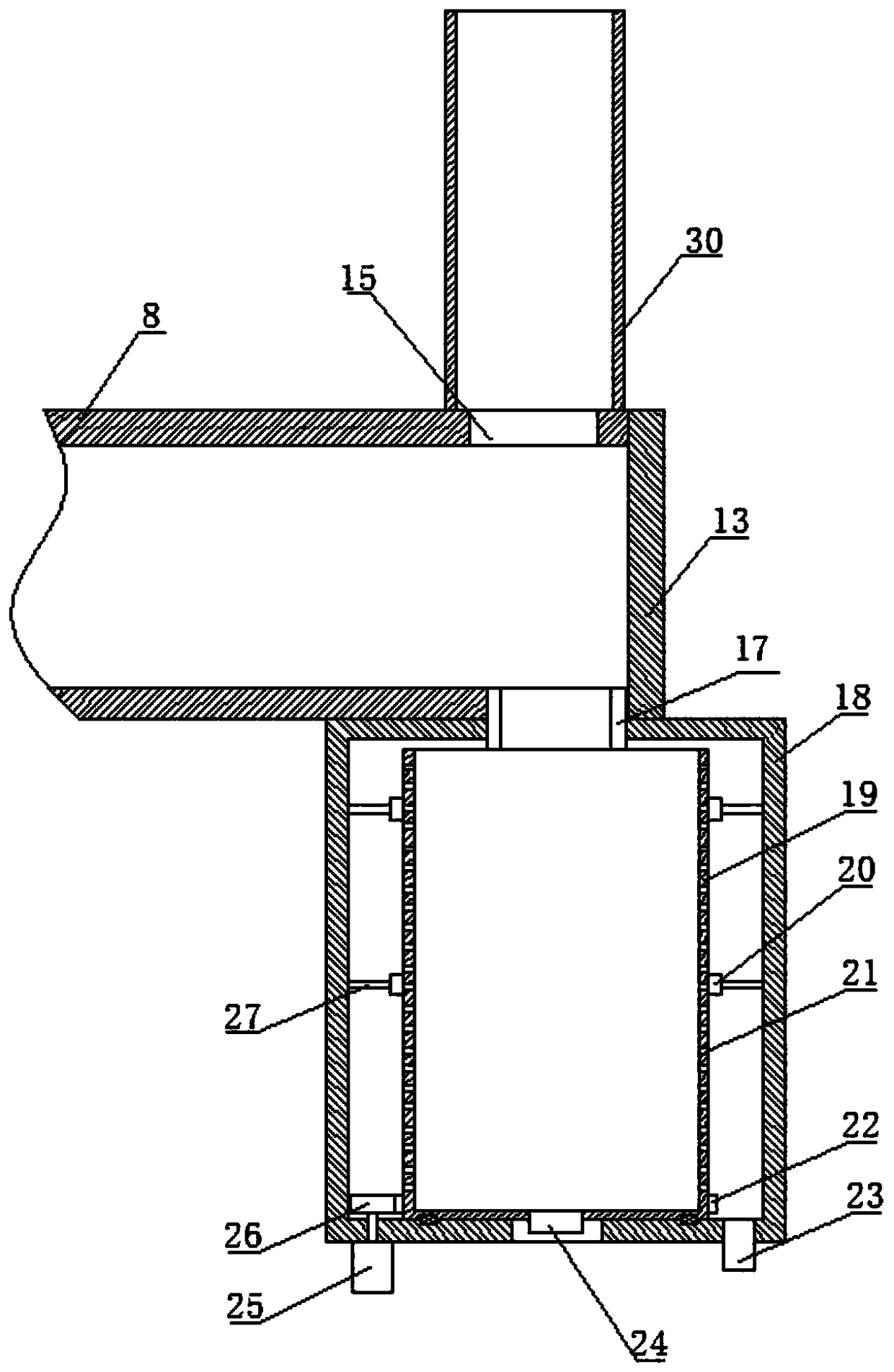

[0021] Figure 1-2 It shows a kind of furnace dust removal equipment provided by the present invention, which includes a dust removal cover body 1, and a plurality of baffle plate groups 2 are arranged on the lower end of the dust removal cover body 1, and each baffle plate group 2 includes a top-to-bottom A plurality of baffles arranged at intervals, and two adjacent baffles are connected by iron chains; the upper end of the dust removal hood body 1 is provided with a transverse flue 8, and the smoke outlet end of the transverse flue 8 is provided with a cover plate 13, The upper end of the horizontal flue 8 is provided with a smoke outlet 15, and the lower end is provided with a slag outlet; the smoke outlet 15 is arranged correspondingly to the upper and lower sides of the slag outlet; the horizontal flue 8 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com