Sodium ion battery electrode and preparation method thereof

A sodium-ion battery and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor rate performance, cycle performance, and poor electrochemical performance, and achieve excellent electrochemical performance, low equipment requirements, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for a sodium ion battery electrode, comprising the steps of:

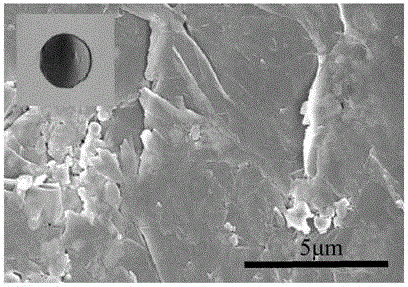

[0032] (1) 0.3g graphene, 0.7g P2-Na 2 / 3 Ni 1 / 3 mn 2 / 3 o 2 The active material was mixed with 100mL ethanol, ultrasonically dispersed for 30 minutes, and the dispersion liquid was obtained;

[0033] (2) Under the pressure of -1atm, pass the dispersed material liquid through a microporous filter membrane with a pore size of 100nm, and suction filter for 12 hours to obtain a composite material;

[0034] (3) Vacuum-dry the composite material at 120°C for 24 hours, slice it, and obtain it.

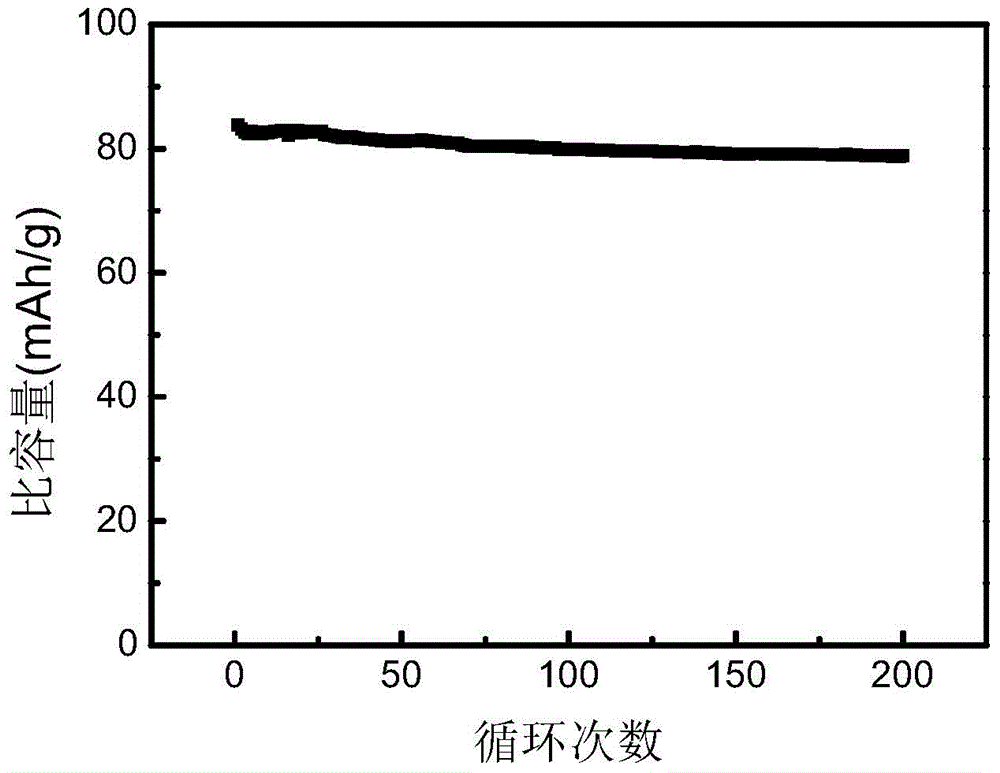

[0035] The prepared sodium ion battery electrode is used as a working electrode, and the metal sodium sheet is used as a counter electrode, containing 1mol / L NaClO 4 The EC:PC (1:1) organic solution is used as the electrolyte, and it is assembled into a button battery in a glove box filled with argon atmosphere for electrochemical performance testing. The charge and discharge cut-off voltage is 2V-4...

Embodiment 2

[0037] A preparation method for a sodium ion battery electrode, comprising the steps of:

[0038] (1) 0.1g graphene, 0.9g Na 3 V 2 (PO 4 ) 3 The active material was mixed with 300mL ethanol, and ultrasonically dispersed for 20 minutes to obtain a dispersion liquid;

[0039] (2) Under the pressure of -0.8atm, pass the dispersed material liquid through a microporous membrane with a pore size of 200nm, and filter it for 10 hours to obtain a composite material;

[0040] (3) Vacuum-dry the composite material at 100°C for 20 hours, slice it, and obtain it.

[0041] The obtained sodium ion battery electrode is used as the working electrode, and the button battery assembly and test are the same as in Example 1. It is measured that the reversible capacity is 91mAhg under the charging and discharging conditions of 2.6V-3.7V and 1C. -1 ; The 10C charge and discharge performance test shows that its 10C / 1C rate performance is 58%.

Embodiment 3

[0043] A preparation method for a sodium ion battery electrode, comprising the steps of:

[0044] (1) Mix 0.5g of graphene, 0.5g of hard carbon active material and 200mL of ethanol, and ultrasonically disperse for 60 minutes to obtain a dispersion liquid;

[0045] (2) Under the pressure of -0.9atm, pass the dispersed material liquid through a microporous membrane with a pore size of 300nm, and filter it for 20 hours to obtain a composite material;

[0046] (3) Vacuum dry the composite material at 120°C for 48 hours, slice it, and obtain it.

[0047] The obtained sodium ion battery electrode is used as a working electrode, and the assembled button battery is the same as in Example 1. It is measured that under the charging and discharging conditions of 2V-0.1V, 1C, its reversible capacity is 273mAhg -1 ; The 10C charge and discharge performance test shows that its 10C / 1C rate performance is 79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com