Preparation method for full carbon fibre composite paper

A technology of carbon fiber and composite paper, which is applied in special paper, synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, etc., can solve problems such as moisture resistance limitations, reduce surface tension, enhance binding force, improve The effect of the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Cotton fibers are beaten to a beating degree of 40 ° SR with a PFI mill;

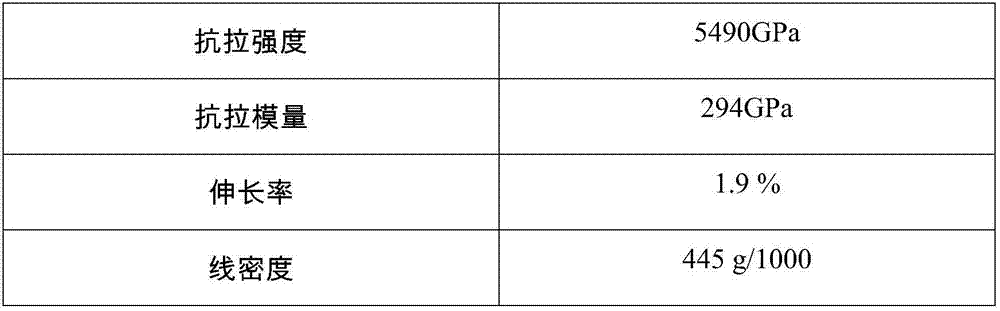

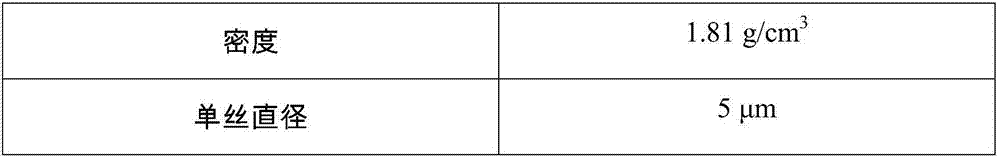

[0041] (2) The polyacrylonitrile-based carbon fiber with a length of 5 mm and a diameter of 5 μm was impregnated with acetone for 40 min;

[0042] (3) Soak the carbon fiber through the above-mentioned treatment with concentrated nitric acid for 40min and wash it for later use;

[0043] (4) ultrasonically treat the carbon fiber after the above treatment with coupling agent KH-550 for 1 h, and the mass fraction of the KH-550 solution is 10%; ..

[0044] (5) Soak the cotton fibers after the beating treatment in step (1) with coupling agent KH-550 for 1h, and the mass fraction of the KH-550 solution is 10%;

[0045] (6) above-mentioned carbon fiber and cotton fiber are placed in deflagging machine together and add water and decompose, the mass fraction ratio of carbon fiber and plant fiber is 40% and 60%;

[0046] (7) Polyethylene oxide (PEO) is added in the deflagging machine and deflagrated t...

Embodiment 2

[0051] (1) Cotton fibers are beaten to a beating degree of 45 ° SR with a PFI mill;

[0052] (2) The polyacrylonitrile-based carbon fiber with a length of 6 mm and a diameter of 5 μm was impregnated with acetone for 50 min;

[0053] (3) soak the carbon fiber through the above-mentioned treatment with concentrated sulfuric acid for 50min and wash it for later use;

[0054] (4) ultrasonically treat the carbon fiber after the above treatment with coupling agent KH-560 for 1 h, and the mass fraction of the KH-560 solution is 10%;

[0055] (5) Soak the cotton fibers after the beating treatment in step (1) with coupling agent KH-550 for 1h, and the mass fraction of the KH-550 solution is 10%;

[0056] (6) above-mentioned carbon fiber and cotton fiber are placed in deflagging machine together and add water and decompose, the mass fraction ratio of carbon fiber and plant fiber is 45% and 55%;

[0057] (7) Add anionic polyacrylamide (APAM) into the deflagging machine and decompose to...

Embodiment 3

[0062] (1) beating the cotton fiber with a PFI mill until the degree of beating is 50 ° SR;

[0063] (2) The polyacrylonitrile-based carbon fiber with a length of 4 mm and a diameter of 5 μm was impregnated with acetone for 35 minutes;

[0064] (3) Soak the above-mentioned carbon fiber with concentrated sodium hydroxide solution for 45 minutes and wash it for later use;

[0065] (4) ultrasonically treat the above-mentioned treated carbon fibers with coupling agent KH-550 for 1.5 h, and the mass fraction of the KH-550 solution is 10%;

[0066] (5) Soak the cotton fibers after the beating treatment in step (1) with coupling agent KH-550 for 1h, and the mass fraction of the KH-550 solution is 10%;

[0067] (6) above-mentioned carbon fiber and cotton fiber are placed in deflagging machine together and add water and decompose, the mass fraction ratio of carbon fiber and plant fiber is 50% and 50%;

[0068] (7) polyvinyl alcohol (PVA) is added in the disintegrating machine to disi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com