Coil element of winding inductor and manufacturing method thereof

A technology of coil components and wire-wound inductors, which is applied in the field of inductors, can solve problems such as increasing product installation space, increasing product costs, and cumbersome manufacturing processes, and achieves improved impact resistance, increased mechanical reliability of products, and improved inductance. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

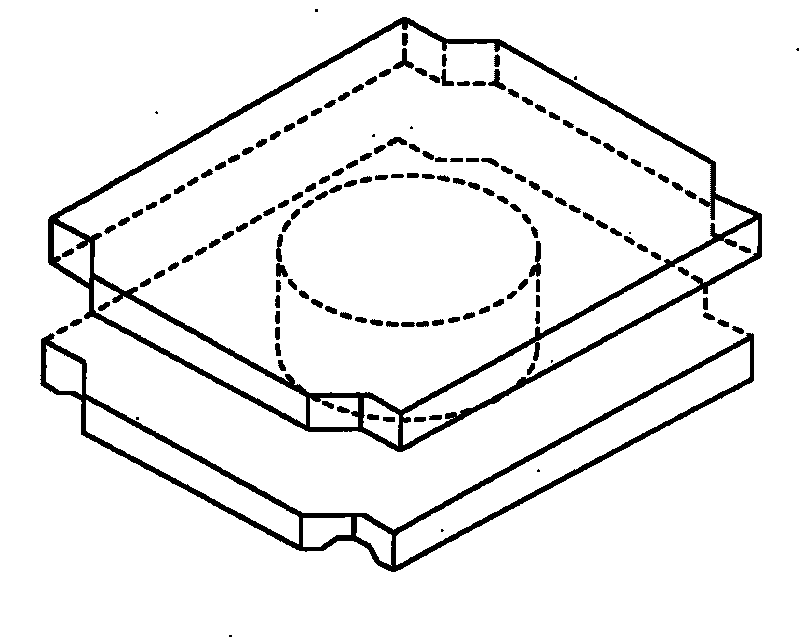

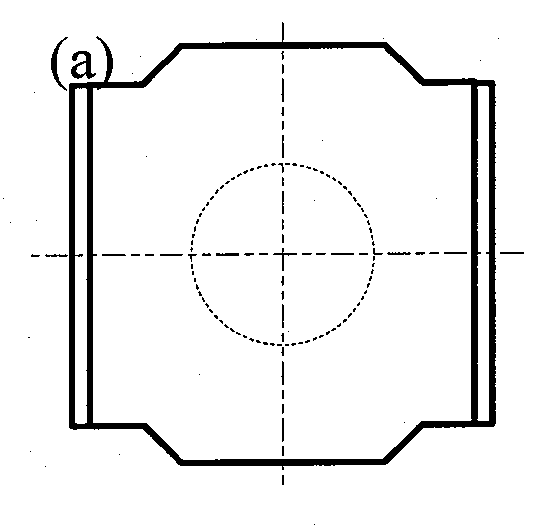

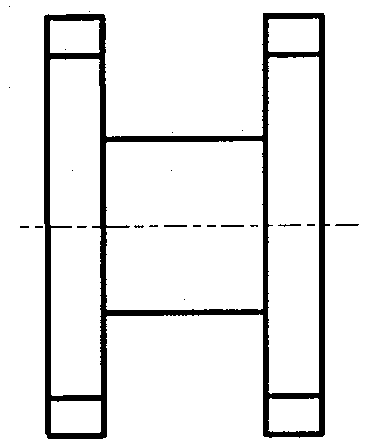

[0034] Such as Figure 1 to Figure 5 As shown, one embodiment of a wirewound inductor assembly includes a ferrite drum core and a wirewound coil. The drum-shaped magnetic core has an upper magnetic core blade 11, a lower magnetic core blade 12 and a cylindrical winding core portion 13 connecting the upper and lower magnetic core blades, and the winding coil 31 is wound on the winding core portion 13, and its two ends are electrically connected. Connected to the external connection electrode 22 on the lower core blade 12 . The wound inductance coil component also has a magnetic mixed material mixed with magnetic powder and glue. After the magnetic mixed material is cured, a glue curing part 4 between the upper and lower magnetic core blades is formed, which covers the upper and lower magnetic core blades. The winding coil is filled in the space between the upper and lower magnetic core blades 11, 12. Wherein, the weight ratio of magnetic powder to glue is not lower than 10:8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com