Glass paste

A technology of glass paste and methyl, which is applied in the field of glass paste, and can solve the problems of adhesive resin component compatibility, adhesion, insufficient sandblasting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

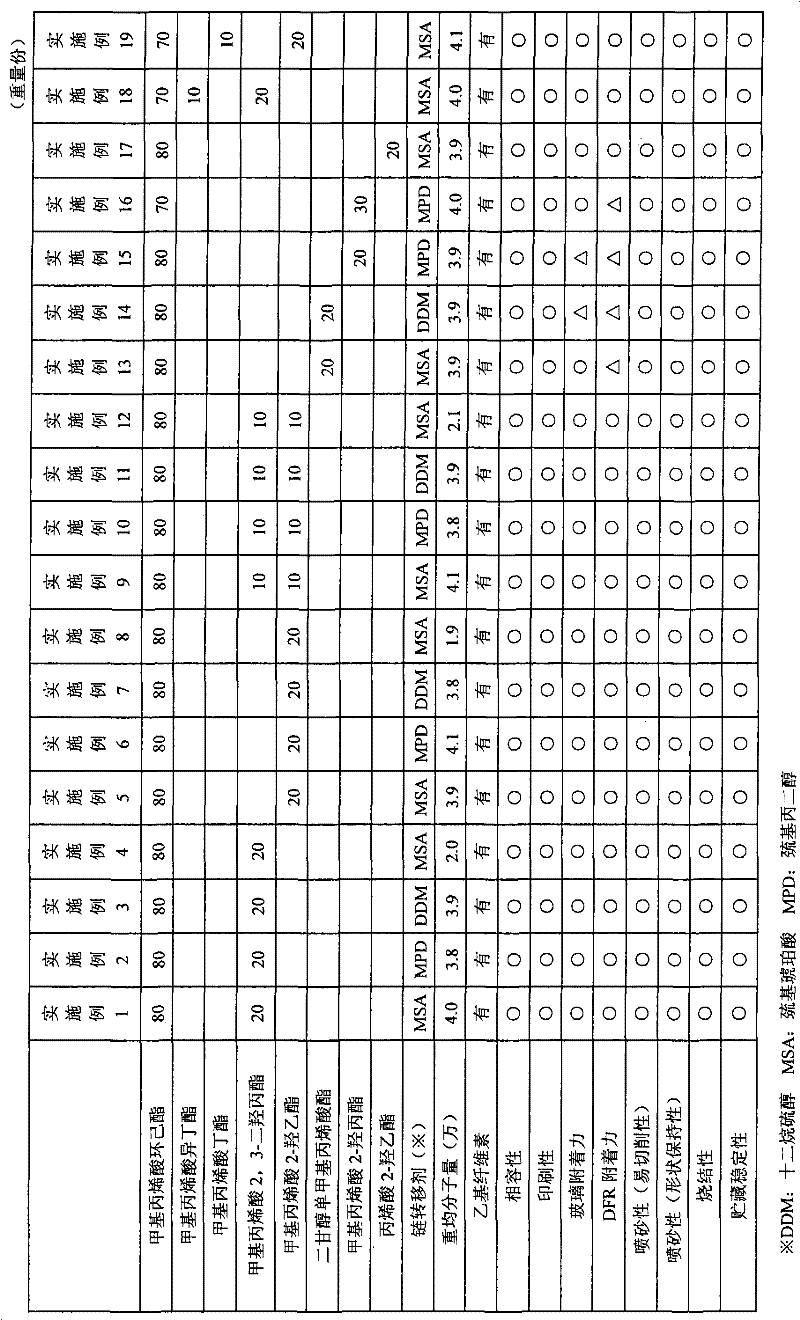

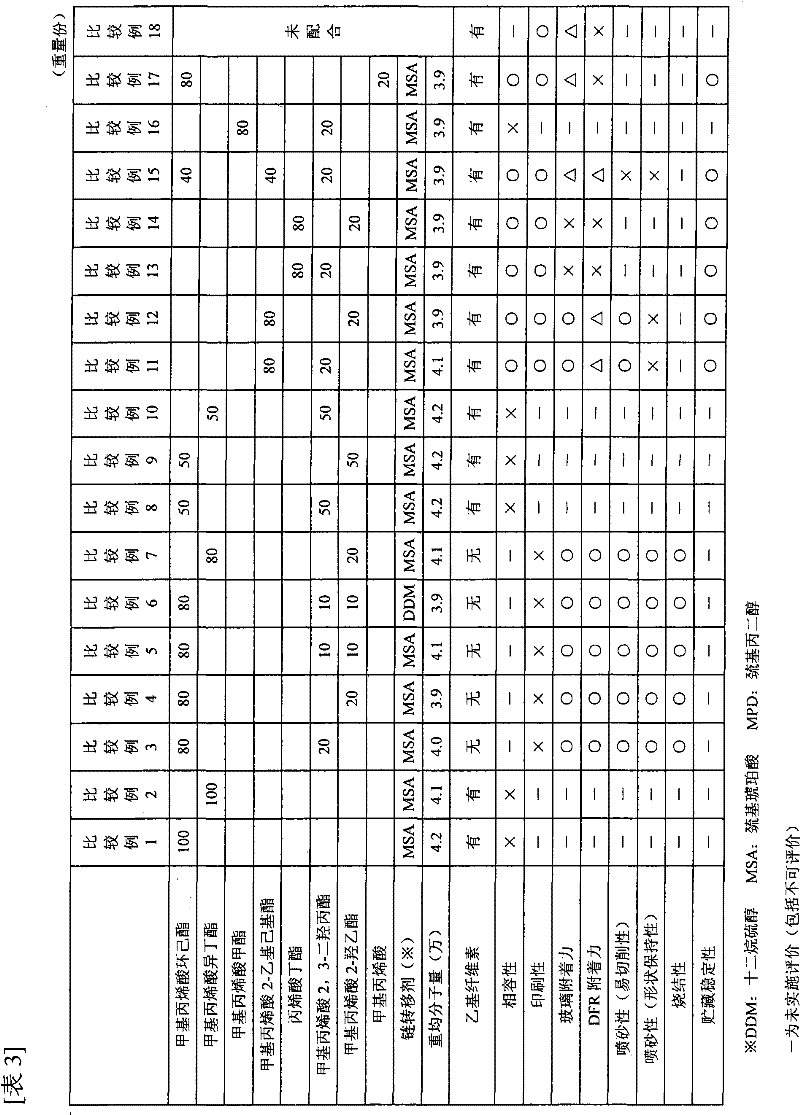

Examples

Embodiment 1

[0057] In a 2L separable flask equipped with a stirrer, a cooler, a thermometer, a hot water bath, and a nitrogen inlet, 80 parts by weight of cyclohexyl methacrylate (manufactured by NOF Corporation: BLEMMER CHMA), 2,3 - 20 parts by weight of dihydroxypropyl ester (manufactured by NOF Corporation: BLEMMERGLM), mercaptosuccinic acid (manufactured by Wako Pure Chemical Industries, Ltd.) as a chain transfer agent, 100 parts by weight of ethyl acetate (manufactured by Wako Pure Chemical Industries, Ltd.) as an organic solvent , to obtain a monomer mixture.

[0058] Dissolved oxygen was removed by bubbling the obtained monomer mixture with nitrogen for 20 minutes, and then the inside of the separable flask system was replaced with nitrogen, and the temperature was raised while stirring until the hot water bath boiled. A solution obtained by diluting the polymerization initiator with ethyl acetate was added. In addition, the polymerization initiator was added several times during ...

Embodiment 2

[0063] A glass paste was prepared in the same manner as in Example 1 except that the chain transfer agent used was changed to mercaptopropylene glycol (manufactured by Wako Pure Chemical Industries, Ltd.) and the weight average molecular weight was changed to the value described in Table 1.

Embodiment 3

[0065] The chain transfer agent used was changed to dodecyl mercaptan (manufactured by Wako Pure Chemical Industries, Ltd.), and the weight average molecular weight was changed to the value recorded in Table 1, except that it was carried out in the same manner as in Example 1 to prepare a glass paste .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com