Barium niobate system microwave dielectric ceramic material and preparation method and application thereof

A technology of microwave dielectric ceramics and barium niobate, applied in waveguide devices, resonators, circuits, etc., can solve the problems of high sintering temperature and difficulty in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

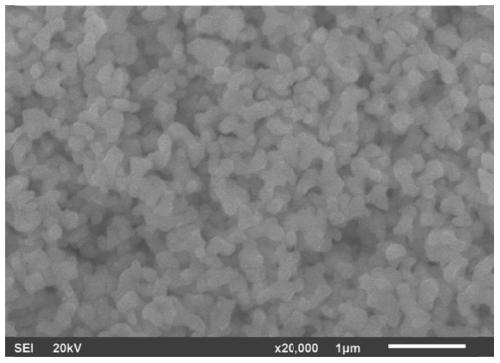

Image

Examples

Embodiment 1

[0035] The barium niobate system microwave dielectric ceramic material described in this embodiment, based on the total amount of raw materials for its preparation, includes the following components in mass content:

[0036]

[0037]

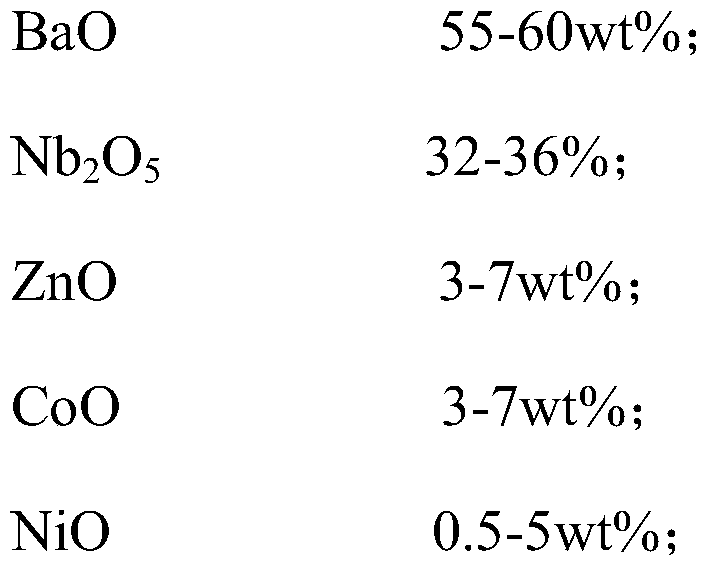

[0038] Specifically, the low-melting glass powder includes the following components by weight:

[0039]

[0040] The preparation method of the barium niobate system microwave dielectric ceramic material described in this embodiment comprises the following steps:

[0041] (1) According to the selected mass content ratio, weigh the corresponding weight of BaCO 3 , Nb 2 o 5 , ZnO, CoO, NiO, add water (material: water = 1:0.4) and ammonium acrylate dispersant (accounting for 0.6wt% of the powder amount) and mix well, use a ball mill to pre-mix for 3h, and after ball milling, Use a horizontal sand mill (the grinding medium adopts 1.5mm zirconium balls) for further dispersion to obtain a uniformly dispersed slurry;

[0042] (2) Microwave-dr...

Embodiment 2

[0049] The barium niobate system microwave dielectric ceramic material described in this embodiment, based on the total amount of raw materials for its preparation, includes the following components in mass content:

[0050]

[0051] Specifically, the low-melting glass powder includes the following components by weight:

[0052]

[0053]

[0054] The preparation method of the barium niobate system microwave dielectric ceramic material described in this embodiment comprises the following steps:

[0055] (1) According to the selected mass content ratio, weigh the corresponding weight of BaCO 3 , Nb 2 o 5 , ZnO, CoO, NiO, add water (material: water = 1:0.6) and ammonium acrylate dispersant (accounting for 0.4wt% of the powder amount) and mix well, use a ball mill to pre-mix for 3h, and after ball milling, Use a horizontal sand mill (the grinding medium adopts 1.5mm zirconium balls) for further dispersion to obtain a uniformly dispersed slurry;

[0056] (2) Use a micr...

Embodiment 3

[0063] The barium niobate system microwave dielectric ceramic material described in this embodiment, based on the total amount of raw materials for its preparation, includes the following components in mass content:

[0064]

[0065] Specifically, the low-melting glass powder includes the following components by weight:

[0066]

[0067] The preparation method of the barium niobate system microwave dielectric ceramic material described in this embodiment comprises the following steps:

[0068] (1) According to the selected mass content ratio, weigh the corresponding weight of BaCO 3 , Nb 2 o 5 , ZnO, CoO, NiO, add water (material: water = 1:0.5) and ammonium acrylate dispersant (accounting for 0.5wt% of the amount of the crystal phase mixture) and mix evenly, use a ball mill to pre-mix for 3h, and in the ball mill Finally, use a horizontal sand mill (the grinding medium adopts 1.5mm zirconium balls) to further disperse to obtain a uniformly dispersed slurry;

[0069]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com