Silver fine particles, production process therefor, conductive paste, conductive membrane and electronic device, containing said silver fine particles

A manufacturing method and technology of silver particles, applied in the field of conductive paste, can solve problems such as being difficult to oxidize, and achieve the effects of reducing carbon content, excellent low-temperature sinterability, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0084]

[0085] After adding 5.16 kg of silver nitrate, 25.8 L of methanol, and 4.89 kg of n-butylamine into a 50 L container, they were mixed and stirred while cooling to below 15° C. to prepare liquid A. Separately, 27.8 L of water and 8.03 kg of erythorbic acid were weighed in a 50 L container, stirred and dissolved, then 3.78 g of sodium chloride was added, and mixed and stirred while cooling to below 15° C., to prepare B liquid.

[0086] Next, while mixing liquid A and liquid B using a static mixer, add them to a 7 L container containing water, cool the reaction system to below 25°C, and stir for 5 hours, then let stand for 30 minutes to make the solid content settlement. After removing the supernatant by decantation, suction filtration was performed using filter paper, followed by washing and filtration with methanol and pure water.

[0087] A part of the solid content of the obtained silver fine particles was dried in a drier at 40° C. for 6 hours, and then pulverize...

Embodiment 2-1

[0089]

[0090] With respect to 100 parts by weight of silver particles in Example 1-1, 11.0 parts by weight of polyester resin and 1.4 parts by weight of curing agent were added, and diethylene glycol monoethyl ether was added so that the content of silver particles in the conductive paste was 70 wt%. After pre-mixing by a rotary mixer "Awatori Rentaro ARE-310" (manufactured by THINKY Co., Ltd., registered trademark), uniform kneading and dispersion were performed using a three-roll mill to obtain a conductive paste.

[0091] The conductive paste obtained above was coated on a polyimide film having a film thickness of 50 μm, and heated at 120° C., 210° C., and 300° C. for 30 minutes, respectively, to obtain conductive coating films.

[0092] The resistivity when the obtained conductive coating film was heat-treated at 120° C. for 30 minutes was 9.5×10 -6 Ω·cm, the resistivity when heat-treated at 210°C for 30 minutes is 4.1×10 -6 Ω·cm, the resistivity is 2.6×10 when heat t...

Embodiment 1-2~1-3

[0094] Examples 1-2 to 1-3 and Comparative Examples 1-1 to 1-2:

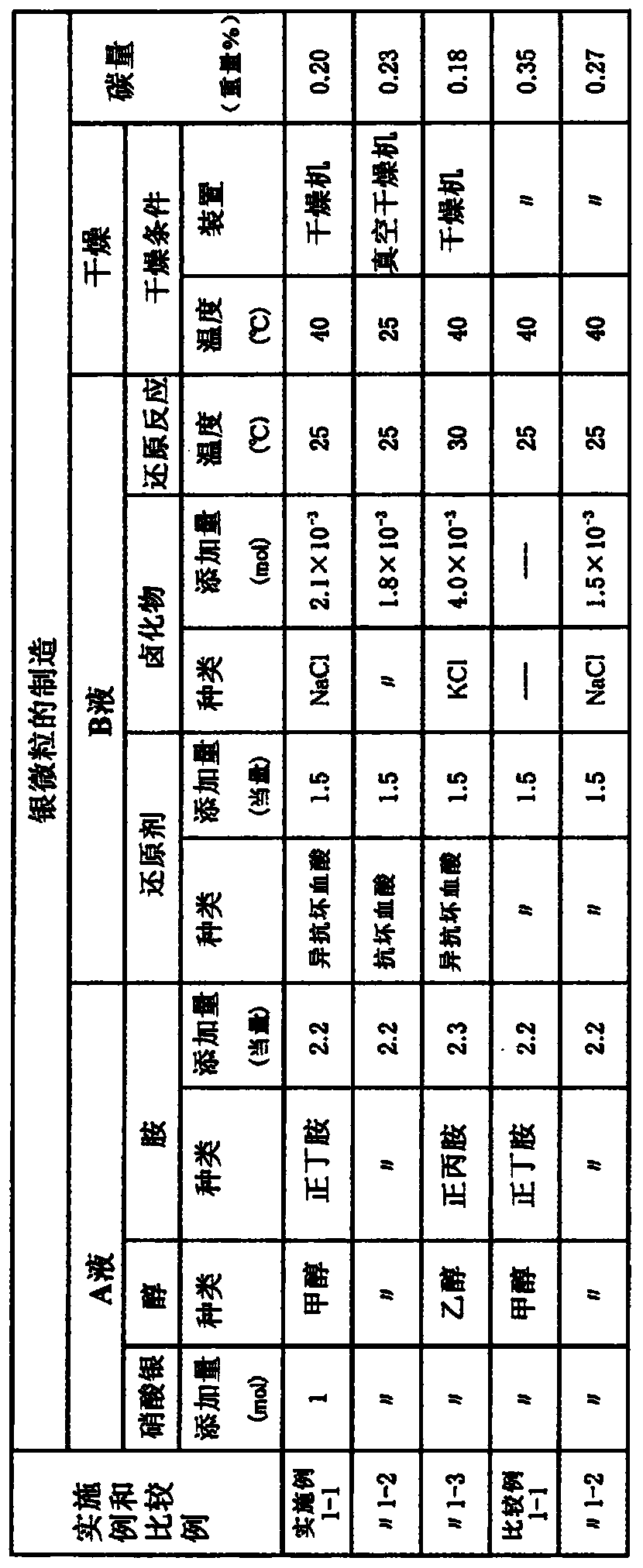

[0095] Silver fine particles were obtained by variously changing the production conditions of silver fine particles.

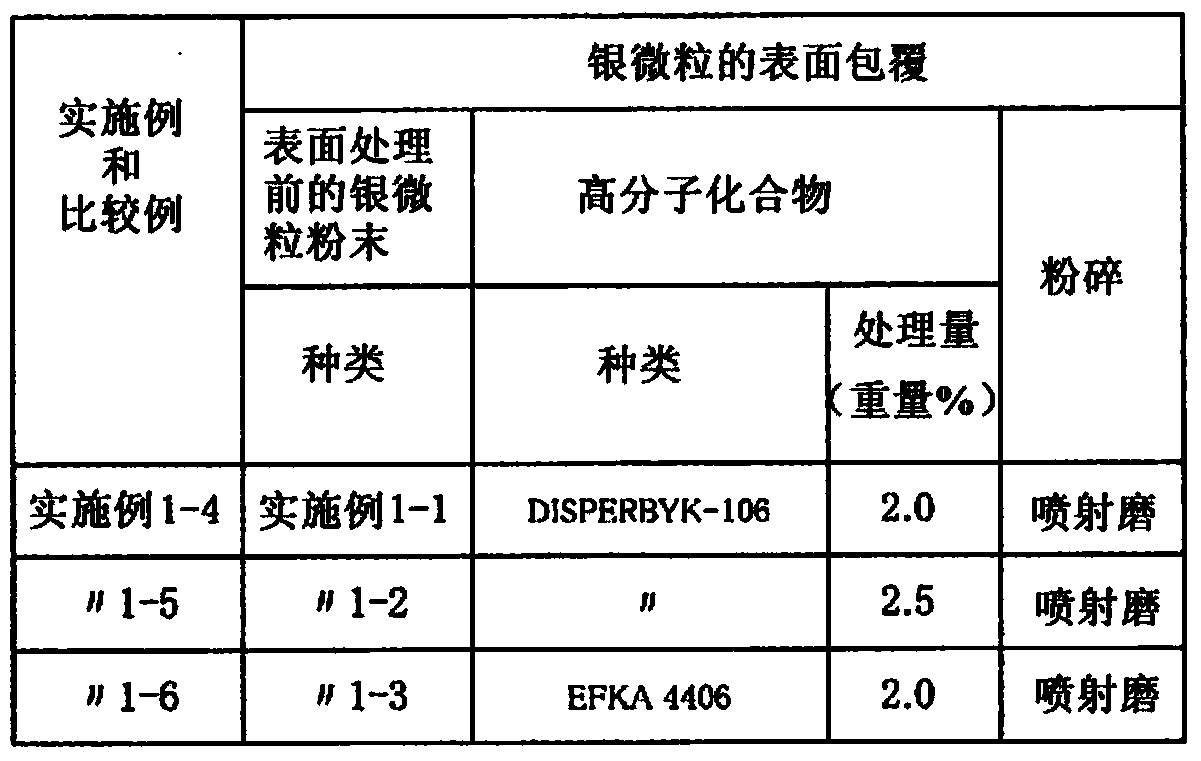

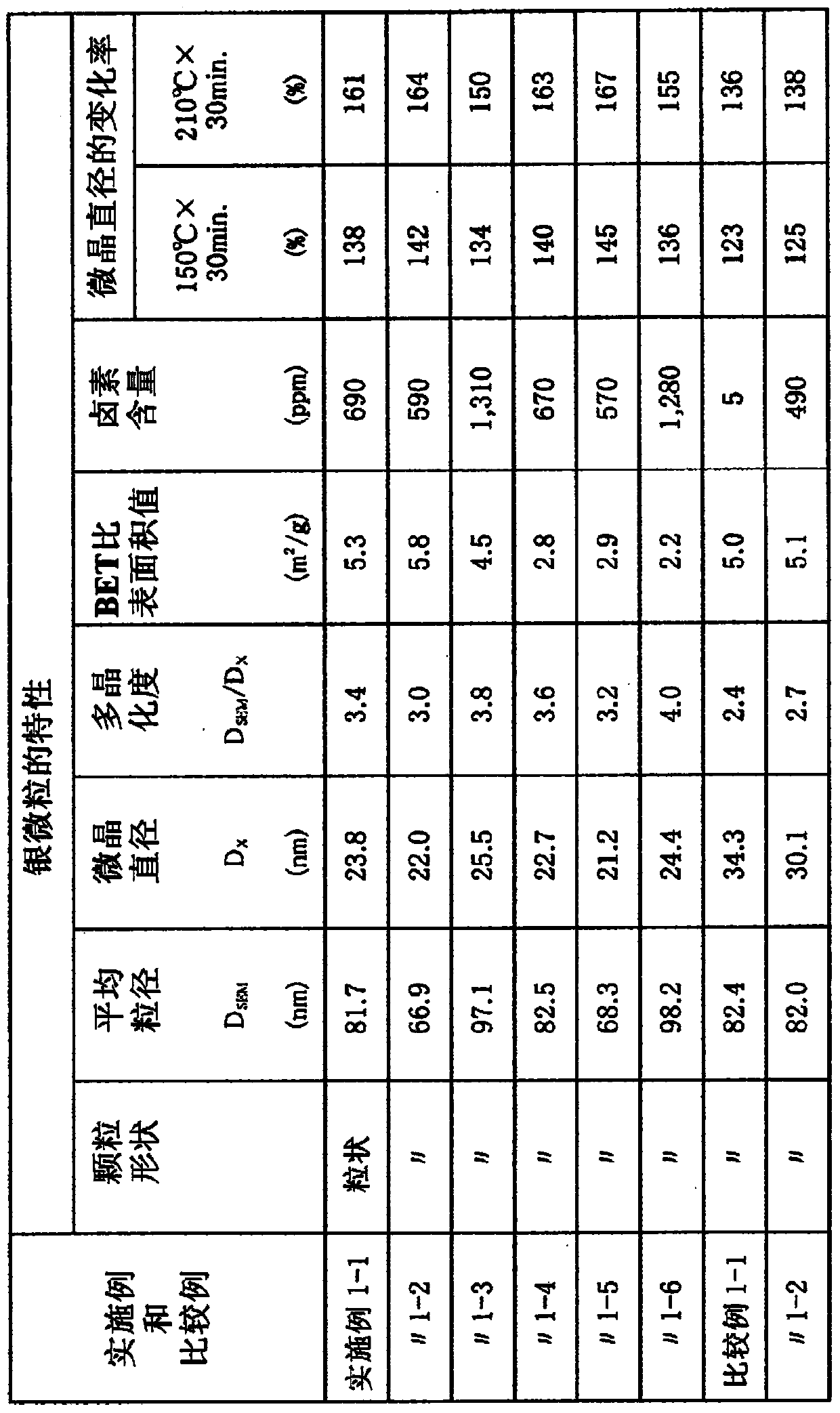

[0096] Table 1 shows the production conditions at this time, and Table 3 shows various characteristics of the obtained silver fine particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Crystallite diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com