Preparation and application of high-potential gradient zinc oxide piezoresistor material

A varistor, zinc oxide technology, applied in varistors, varistor cores, etc., can solve the problems of high sintering temperature and cost increase, and achieve the effects of lower sintering temperature, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

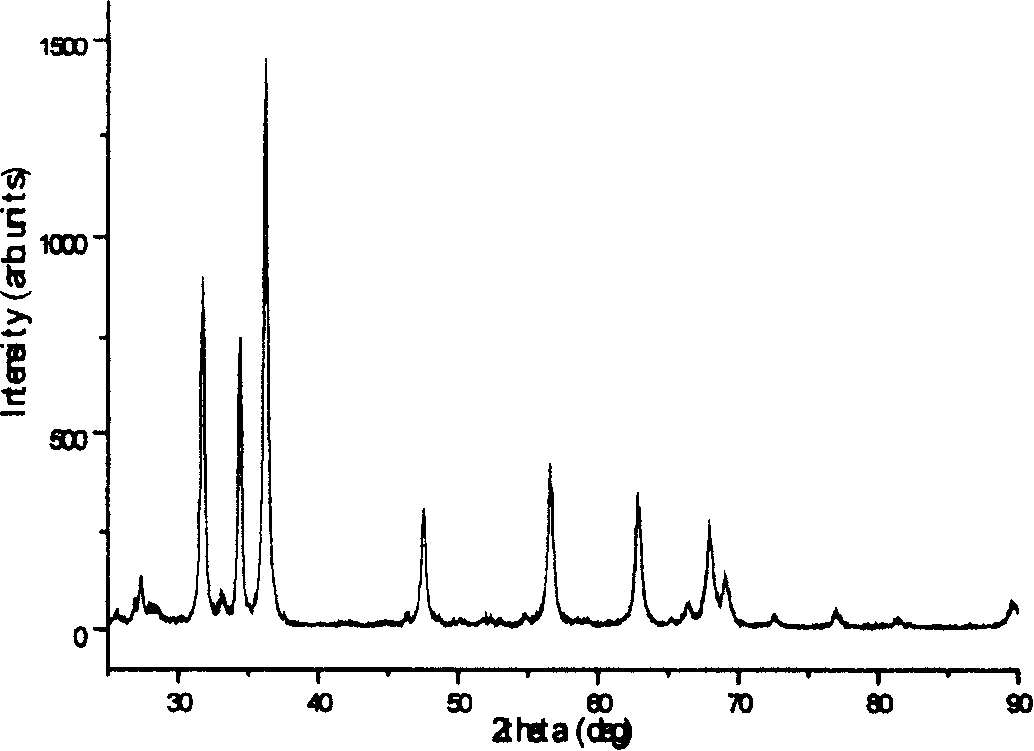

Image

Examples

Embodiment 1

[0046] (1) Preparation of high potential gradient zinc oxide varistor materials

[0047] In the first step, commercially available micron-sized zinc oxide ZnO, bismuth trioxide Bi 2 o 3 , antimony trioxide Sb 2 o 3 , Chromium trioxide Cr 2 o 3 , cobalt trioxide Co 2 o 3 and manganese dioxide MnO 2 Powder as raw material, ZnO: Bi in molar ratio 2 o 3 :Sb 2 o 3 :Cr 2 o 3 :Co 2 o 3 :MnO 2 96.5:0.7:1.0:0.5:0.8:0.5 mixed into metal oxide mixed powder. The high-energy ball mill is a planetary high-energy ball mill, which uses steel wear-resistant balls and nylon tanks. High-energy ball milling conditions: rotating speed 620rpm, ball-to-powder ratio 16:1. Wet mill in absolute ethanol for 2 hours, dry and dry mill for 0.5 hour. In the second step, a 10-ton universal hydraulic press is pressed into blocks, and sintered at a low temperature of 380°C for 1.5 hours in a resistance furnace. In the third step, the sintered mass is pulverized. High energy ball milling co...

Embodiment 2

[0052] (1) Preparation of high potential gradient zinc oxide varistor materials

[0053] In the first step, commercially available micron-sized zinc oxide ZnO, bismuth trioxide Bi 2 o 3 , antimony trioxide Sb 2 o 3 , Chromium trioxide Cr 2 o 3 , cobalt trioxide Co 2 o 3 and manganese dioxide MnO 2 Powder as raw material, ZnO: Bi in molar ratio 2 o 3 :Sb 2 o 3 :Cr 2 o 3 :Co 2 o 3 :MnO 2 96.5:0.7:1.0:0.5:0.8:0.5 mixed into metal oxide mixed powder. The high-energy ball mill is a planetary high-energy ball mill, which uses steel wear-resistant balls and nylon tanks. High-energy ball milling conditions: rotating speed 460rpm, ball-to-powder ratio 20:1. Wet mill in absolute ethanol for 2 hours, dry and dry mill for 0.5 hour. In the second step, a 15-ton universal hydraulic press is pressed into blocks, and sintered at a low temperature of 550 ° C for 2 hours in a resistance furnace. In the third step, the sintered mass is pulverized. High energy ball milling co...

Embodiment 3

[0058] (1) Preparation of high potential gradient zinc oxide varistor materials

[0059] In the first step, commercially available micron-sized zinc oxide ZnO, bismuth trioxide Bi 2 o 3 , antimony trioxide Sb 2 o 3 , Chromium trioxide Cr 2 o 3 , cobalt trioxide Co 2 o 3 and manganese dioxide MnO 2 Powder as raw material, ZnO: Bi in molar ratio 2 o 3 :Sb 2 o 3 :Cr 2 o 3 :Co 2 o 3 :MnO 2 96.5:0.7:1.0:0.5:0.8:0.5 mixed into metal oxide mixed powder. The high-energy ball mill is a planetary high-energy ball mill, which uses steel wear-resistant balls and nylon tanks. High-energy ball milling conditions: rotating speed 320rpm, ball-to-powder ratio 40:1. Wet grinding in absolute ethanol for 8 hours, drying, and dry grinding for 0.5 hours. In the second step, a 25-ton universal hydraulic press is pressed into blocks, and sintered at a low temperature of 630°C for 2.5 hours in a resistance furnace. In the third step, the sintered mass is pulverized. High energy ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com