A kind of daily-use ceramic product with good thermal insulation performance and preparation method thereof

A technology for thermal insulation performance and ceramic products, applied in the field of ceramic products, can solve the problems of inability to meet the use needs of thermal insulation daily ceramic products, poor mechanical properties such as strength, poor comprehensive use performance, etc., and achieves energy saving for sintering and high flexural strength. , the effect of small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

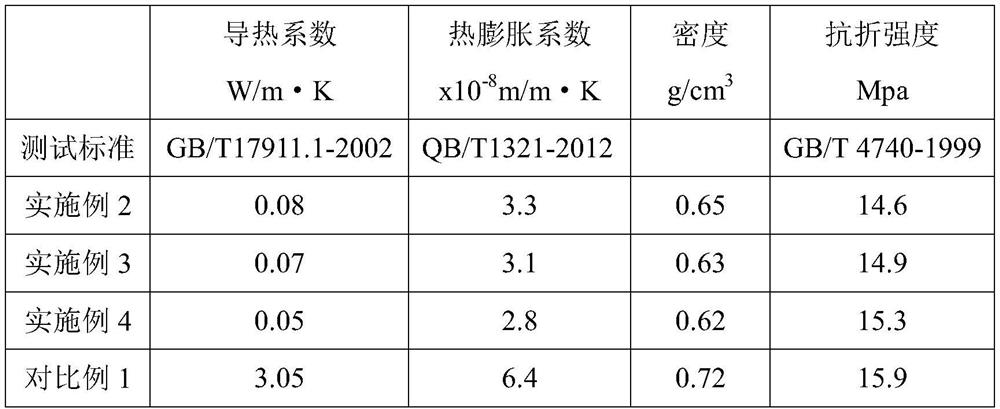

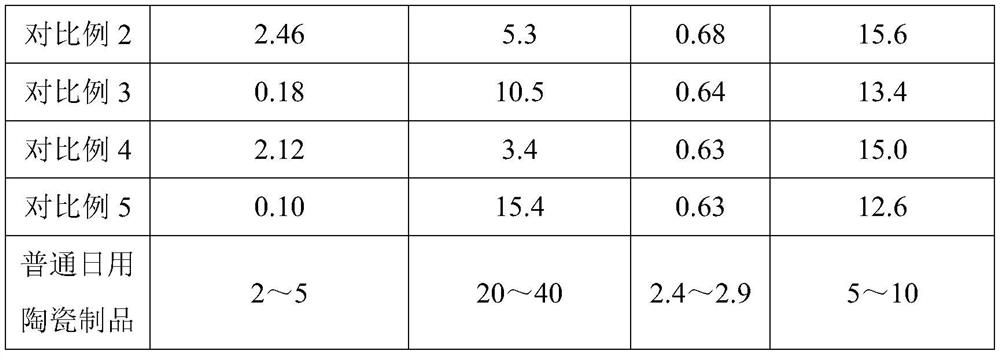

Examples

Embodiment 1

[0047] A daily-use ceramic product with good thermal insulation performance is made from the following raw materials by weight:

[0048] 20-26 parts of albite,

[0049] 15-19 parts of anorthite,

[0050] 30-40 parts of calcite,

[0051] 25-32 parts of attapulgite clay,

[0052] 10-14 parts of sodium bentonite,

[0053] 5 to 7 parts of monetite,

[0054] Quartz 10 to 14 parts,

[0055] 8-11 parts of aluminum silicate fiber tube,

[0056] 4 to 5.5 parts of sodium silicate,

[0057] 2.2 to 3 parts of foaming agent,

[0058] Foam stabilizer 0.9 to 1.3 parts,

[0059] Water reducing agent 0.8 to 1.1 parts.

[0060] In this embodiment, the household ceramic product with good thermal insulation performance is preferably made from the following raw materials by weight:

[0061] 23 parts of albite, 17 parts of anorthite, 35 parts of calcite, 29 parts of attapulgite, 12 parts of sodium bentonite, 6 parts of monetite, 12 parts of quartz, 9.5 parts of aluminum silicate fiber tub...

Embodiment 2

[0072] A daily-use ceramic product with good thermal insulation performance is made from the following raw materials by weight:

[0073] 20 parts of albite,

[0074] 15 parts of anorthite,

[0075] 30 parts of calcite,

[0076] Attapulgite clay 25 parts,

[0077] 10 parts of sodium bentonite,

[0078] 5 parts of monetite,

[0079] 10 pieces of quartz,

[0080] 8 parts of aluminum silicate fiber tube,

[0081] 4 parts of sodium silicate,

[0082] 2.2 parts of foaming agent,

[0083] 0.9 part of foam stabilizer,

[0084] Water reducing agent 0.8 parts.

[0085] In this embodiment, the foaming agent is sodium dodecylbenzenesulfonate.

[0086] In this embodiment, the water-reducing agent is FDN-II retarding and high-efficiency water-reducing agent.

[0087] In this embodiment, the foam stabilizer is a mixture of polydimethylsiloxane and stearamidopropyl polydimethylsiloxane.

[0088] In this embodiment, the mass ratio of the polydimethylsiloxane and the stearamidopropy...

Embodiment 3

[0095] A daily-use ceramic product with good thermal insulation performance is made from the following raw materials by weight:

[0096] 26 parts of albite,

[0097] 19 parts of anorthite,

[0098] 40 parts of calcite,

[0099] Attapulgite clay 32 parts,

[0100] 14 parts of sodium bentonite,

[0101] 7 parts of monetite,

[0102] 14 pieces of quartz,

[0103] 11 parts of aluminum silicate fiber tube,

[0104] 5.5 parts of sodium silicate,

[0105] 3 parts of foaming agent,

[0106] 1.3 parts of foam stabilizer,

[0107] Water reducing agent 1.1 parts.

[0108] In this embodiment, the foaming agent is sodium dodecylbenzenesulfonate.

[0109] In this embodiment, the water-reducing agent is FDN-II retarding and high-efficiency water-reducing agent.

[0110] In this embodiment, the foam stabilizer is a mixture of polydimethylsiloxane and stearamidopropyl polydimethylsiloxane.

[0111] In this embodiment, the mass ratio of the polydimethylsiloxane and the stearamidopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com