Low-sintering microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic, low-firing technology, applied in the field of microwave dielectric materials, can solve the problems of high cost and large process energy consumption, and achieve the effect of good low-temperature sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

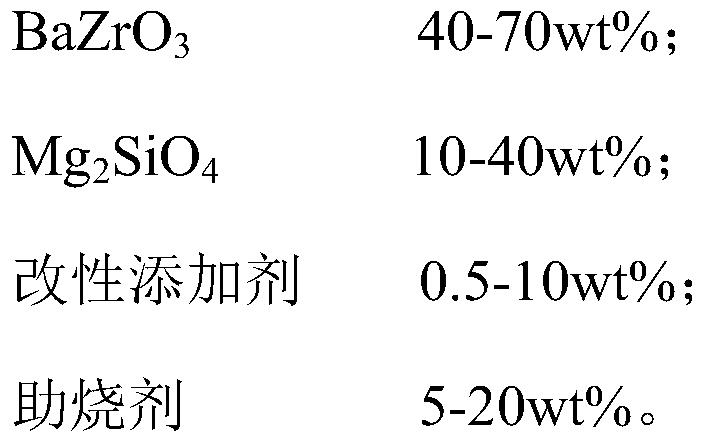

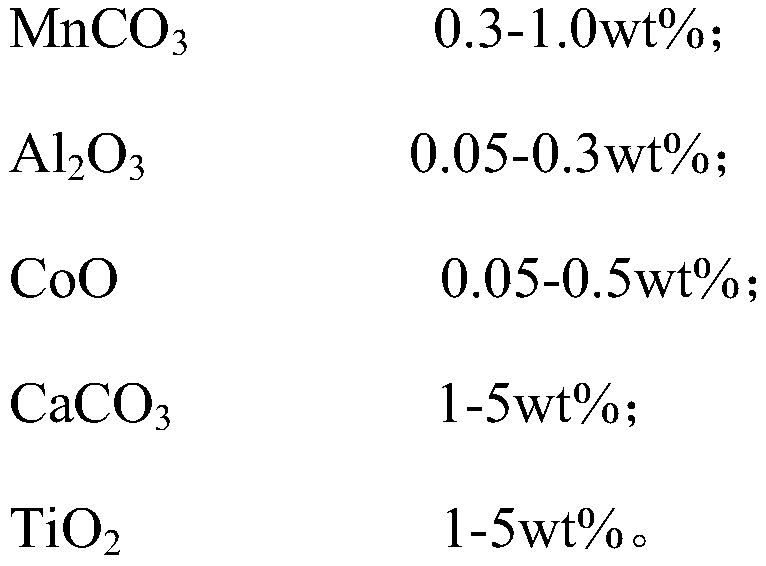

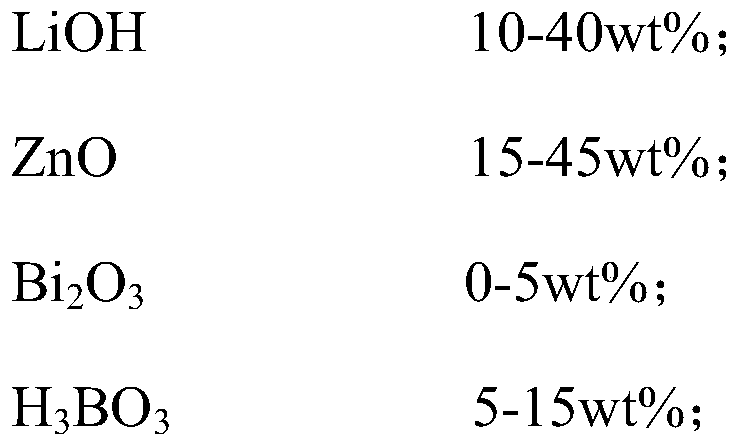

Method used

Image

Examples

experiment example

[0033] The above-mentioned granulated materials were subjected to dry pressing, and the pressed green bodies were respectively heat-preserved and calcined for 3 hours, and the sintering temperature at which the green bodies of each material could be formed was recorded.

[0034] Perform performance tests on the microwave dielectric ceramic materials prepared in the above-mentioned Examples 1-5 and Comparative Examples 1-4, specifically including the dielectric constant of the material, the f*Q value at 25°C, and the frequency temperature coefficient τf;

[0035] The dielectric constant and the f*Q value at 25°C can be obtained by methods known in the prior art;

[0036] The frequency temperature coefficient τf means that it has good temperature characteristics. It is calculated by testing the resonant frequency f at -40°C, 25°C, and 110°C respectively, and is calculated according to the following formula:

[0037] τf=[(f 110℃ -f -40℃ ) / f 25℃ ] / 150*10 6 (ppm / °C).

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com