Fully-prealloyed powder and preparation method thereof

A pre-alloying and powder technology, applied in the field of fully pre-alloyed powder and its preparation, can solve the problems of increased rejection rate, poor formability, limited use ratio, etc., and achieve good low-temperature sinterability, excellent weldability, and excellent resistance. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention also discloses a method for preparing the fully pre-alloyed powder, which includes the following process steps,

[0041] A. Separate a part of Cu from the raw material of the fully pre-alloyed powder as the cladding layer raw material, and the remaining part is the parent core raw material.

[0042] Specifically, the separated Cu as the raw material of the cladding layer accounts for 10-25% by weight of the fully pre-alloyed powder, and the Cu as the raw material of the cladding layer is added in the form of copper oxide.

[0043] B. Using the high-pressure water atomization pulverization method to prepare the matrix core core raw material in step A into matrix core core powder.

[0044]Specifically, the specific process and process conditions of the high-pressure water atomization powder making method are: batching is carried out according to the weight percentage of each component in the parent core raw material, preferably block, rod or sheet raw materi...

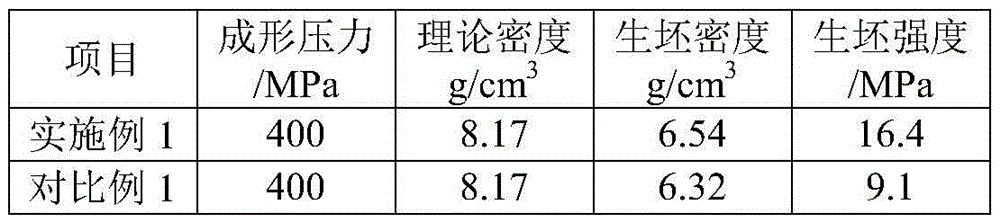

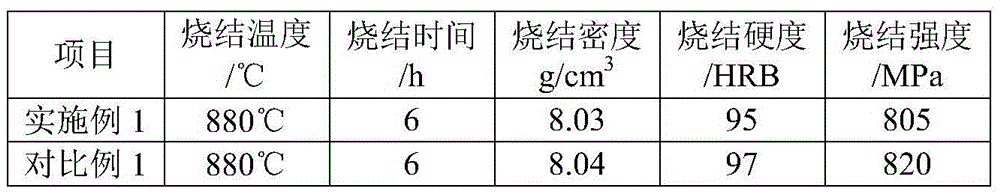

Embodiment 1

[0054] The composition and weight percentage of the fully pre-alloyed powder prepared in this embodiment are predetermined as: Fe62%, Cu20%, Sn4%, Ni8%, Co6%. That is, 100 kg of fully pre-alloyed powder is prepared in this embodiment, Fe accounts for 62 kg, Cu accounts for 20 kg, Sn accounts for 4 kg, Ni accounts for 8 kg, and Co accounts for 6 kg.

[0055] The preparation method of the fully pre-alloyed powder of this embodiment includes the following process steps,

[0056] A. Separate a part of Cu from the raw material of the fully pre-alloyed powder as the cladding layer raw material, and the remaining part is the parent core raw material.

[0057] In this embodiment, Cu used as the raw material of the cladding layer accounts for 15% by weight of the fully pre-alloyed powder. That is, in this embodiment, the cladding layer raw material contains 15 kg of Cu, and the parent core raw material is composed of 62 kg of Fe, 5 kg of Cu, 4 kg of Sn, 8 kg of Ni, and 6 kg of Co.

...

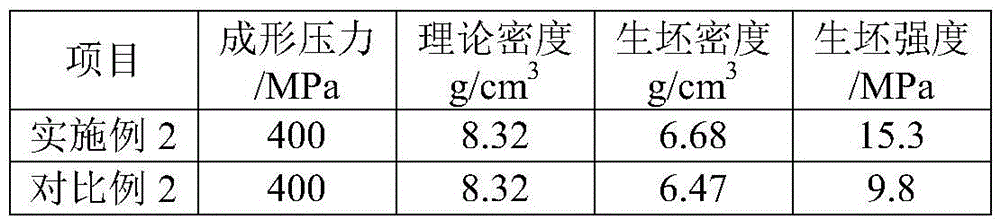

Embodiment 2

[0078] The composition and weight percentage of the fully pre-alloyed powder prepared in this embodiment are predetermined as: Fe38%, Cu40%, Sn10%, Ni8%, Co4%. That is, 100 kg of fully pre-alloyed powder is prepared in this embodiment, Fe accounts for 38 kg, Cu accounts for 40 kg, Sn accounts for 10 kg, Ni accounts for 8 kg, and Co accounts for 4 kg.

[0079] The preparation method of the fully pre-alloyed powder of this embodiment includes the following process steps,

[0080] A. Separate a part of Cu from the raw material of the fully pre-alloyed powder as the cladding layer raw material, and the remaining part is the parent core raw material.

[0081] In this embodiment, Cu used as the raw material of the cladding layer accounts for 25% by weight of the fully pre-alloyed powder. That is, in this embodiment, the cladding layer raw material contains 25 kg of Cu, and the parent core raw material is composed of 38 kg of Fe, 15 kg of Cu, 10 kg of Sn, 8 kg of Ni, and 4 kg of Co....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com