Flame-retardant sheath material for extra-high-voltage cable and preparation method of flame-retardant sheath material

A flame-retardant sheathing, ultra-high voltage technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of decreased mechanical properties of sheathing materials, poor interface compatibility, deterioration of mechanical properties of products, etc., to avoid rapid The effect of growth, improvement of flame retardant performance, and improvement of interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

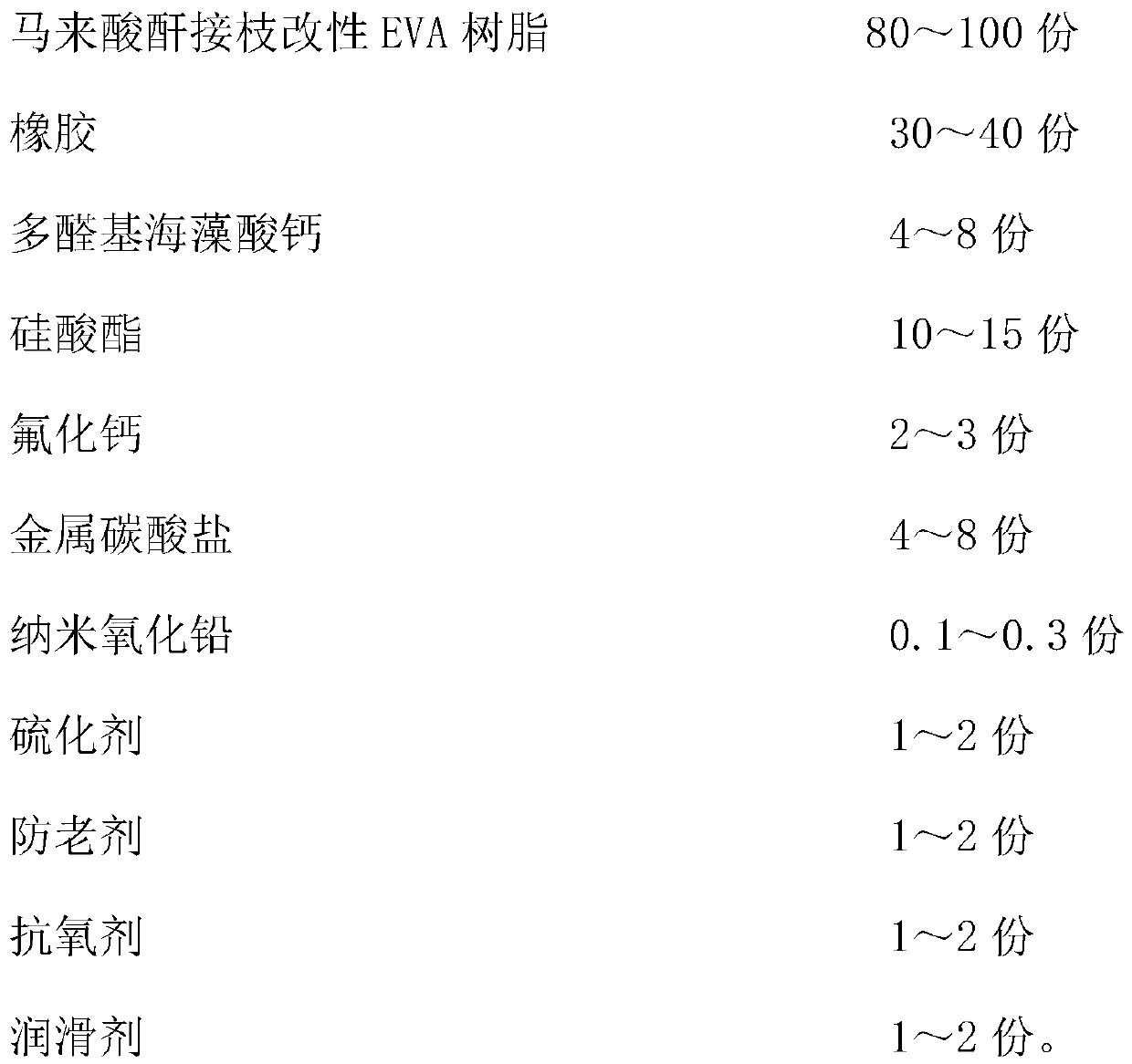

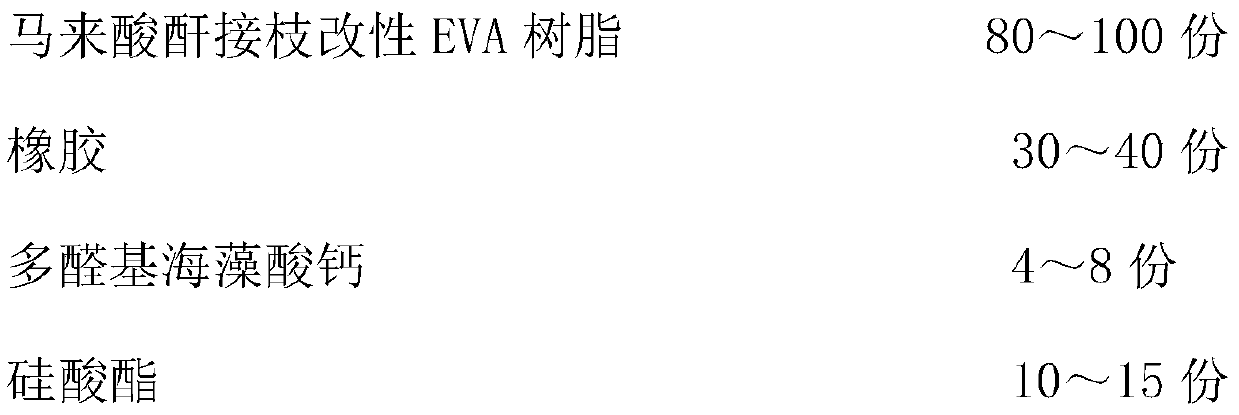

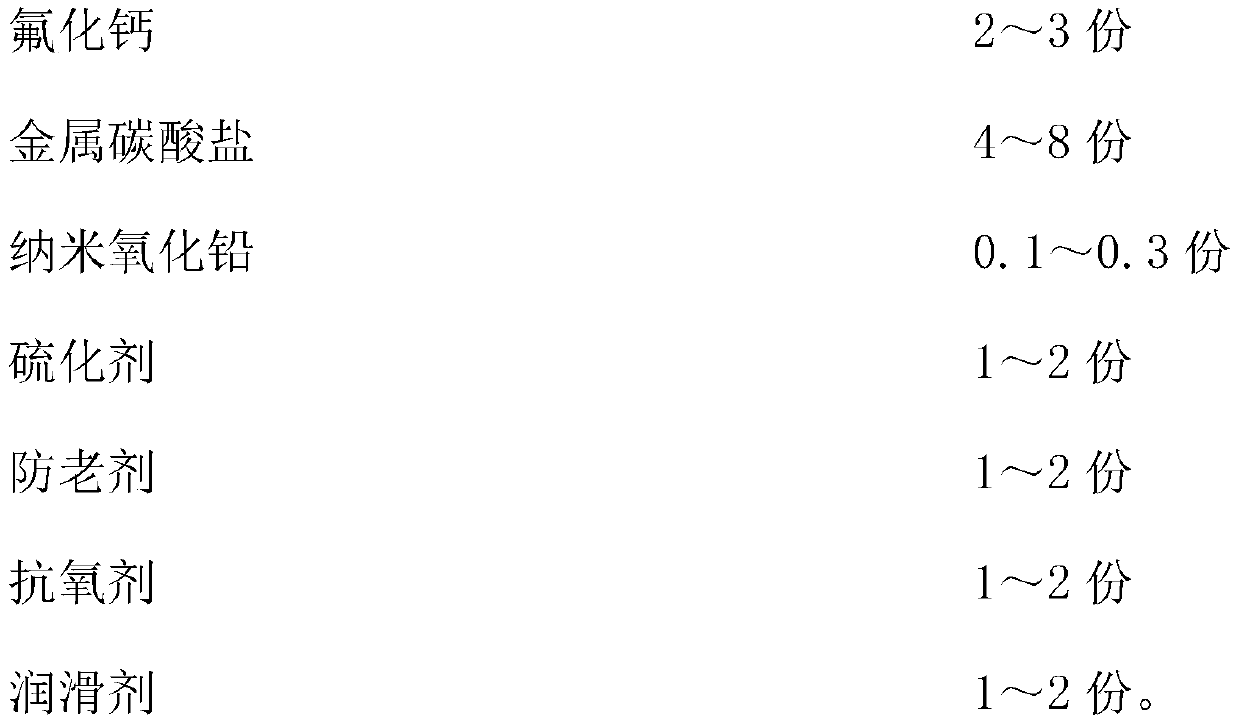

Method used

Image

Examples

Embodiment 1

[0032] Polyaldehyde Calcium Alginate:

[0033] Mix sodium alginate and water at a mass ratio of 1:20, then add sodium periodate that is 0.3 times the mass of sodium alginate, and then heat and stir for 3 hours at a temperature of 65°C and a stirring speed of 200r / min. , after the reaction is completed, under the conditions of temperature 75°C and pressure 400mmHg, concentrate under reduced pressure to 1 / 2 of the original volume of the material to obtain a concentrate, and then transfer the obtained concentrate to a vacuum drying oven, and store it at a temperature of 105°C , vacuum-dried to a constant weight under the condition of 60 Pa to obtain a dried material, and then impregnated the obtained dried material in a calcium chloride solution with a mass fraction of 3%, and then filtered it for 10 minutes under the condition of an ultrasonic frequency of 55 kHz. filter cake, and wash the filter cake with deionized water for 3 times, then transfer the washed filter cake to a va...

Embodiment 2

[0043] Polyaldehyde Calcium Alginate:

[0044]Mix sodium alginate and water at a mass ratio of 1:30, then add sodium periodate that is 0.3 times the mass of sodium alginate, and then heat and stir for 4 hours at a temperature of 70°C and a stirring speed of 300r / min. , after the reaction is completed, under the conditions of temperature 80°C and pressure 410mmHg, concentrate under reduced pressure to 1 / 2 of the original volume of the material to obtain a concentrate, and then transfer the obtained concentrate to a vacuum drying oven, and store it at a temperature of 108°C , vacuum-dried to a constant weight under the condition of 70 Pa to obtain a dry material, and then impregnated the obtained dry material in a calcium chloride solution with a mass fraction of 5%, and then filtered it for 50 minutes under the condition of an ultrasonic frequency of 70 kHz to obtain filter cake, and wash the filter cake with deionized water 4 times, then transfer the washed filter cake to a va...

Embodiment 3

[0054] Polyaldehyde Calcium Alginate:

[0055] Mix sodium alginate and water at a mass ratio of 1:50, then add sodium periodate that is 0.4 times the mass of sodium alginate, and then heat and stir for 5 hours at a temperature of 75°C and a stirring speed of 500r / min. , after the reaction is completed, under the conditions of temperature 85°C and pressure 420mmHg, concentrate under reduced pressure to 1 / 2 of the original volume of the material to obtain a concentrate, and then transfer the obtained concentrate to a vacuum drying oven, and store it at a temperature of 110°C , vacuum-dried to a constant weight under the condition of 80 Pa to obtain a dried material, and then impregnated the obtained dried material in a calcium chloride solution with a mass fraction of 8%, and then filtered it for 100 min under the condition of an ultrasonic frequency of 80 kHz to obtain filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com