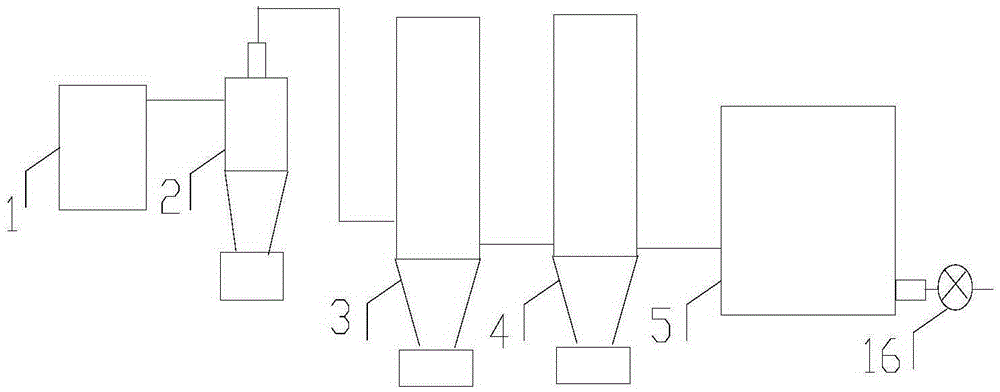

Device and method for improving tar yield by pyrolysis of low-rank coal

A technology of tar yield and low-rank coal, which is applied in the field of devices to increase the yield of low-rank coal pyrolysis tar, can solve the problems of low cost, low tar yield, incomplete recovery of coal pyrolysis tar, etc., and achieve an increase in production efficiency, reducing coal pyrolysis temperature, and reducing the possibility of secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

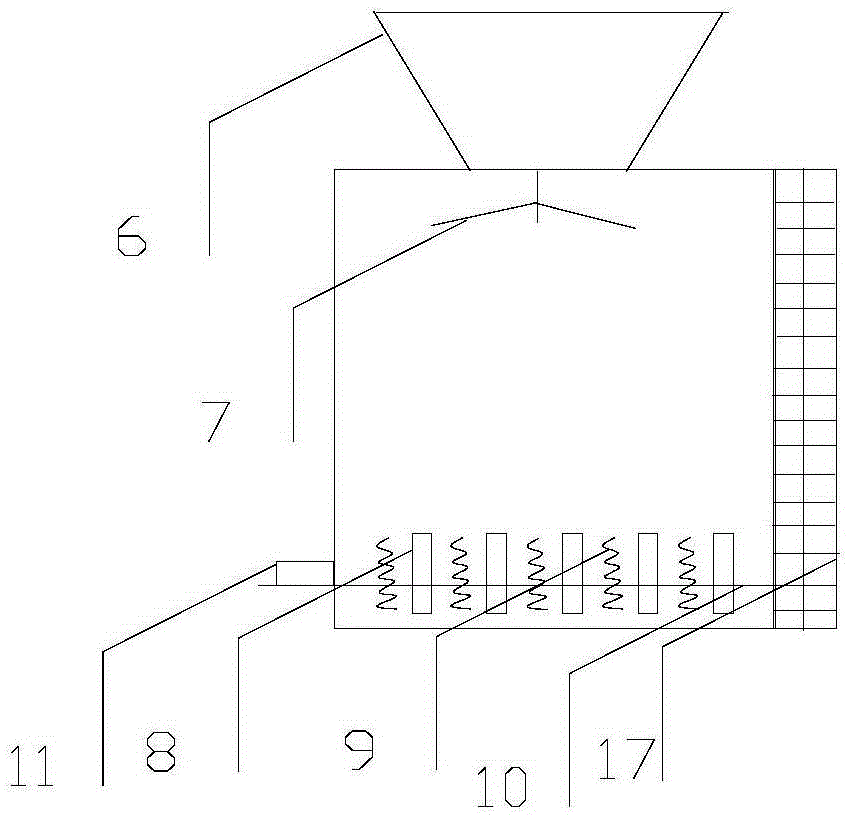

Method used

Image

Examples

Embodiment 1

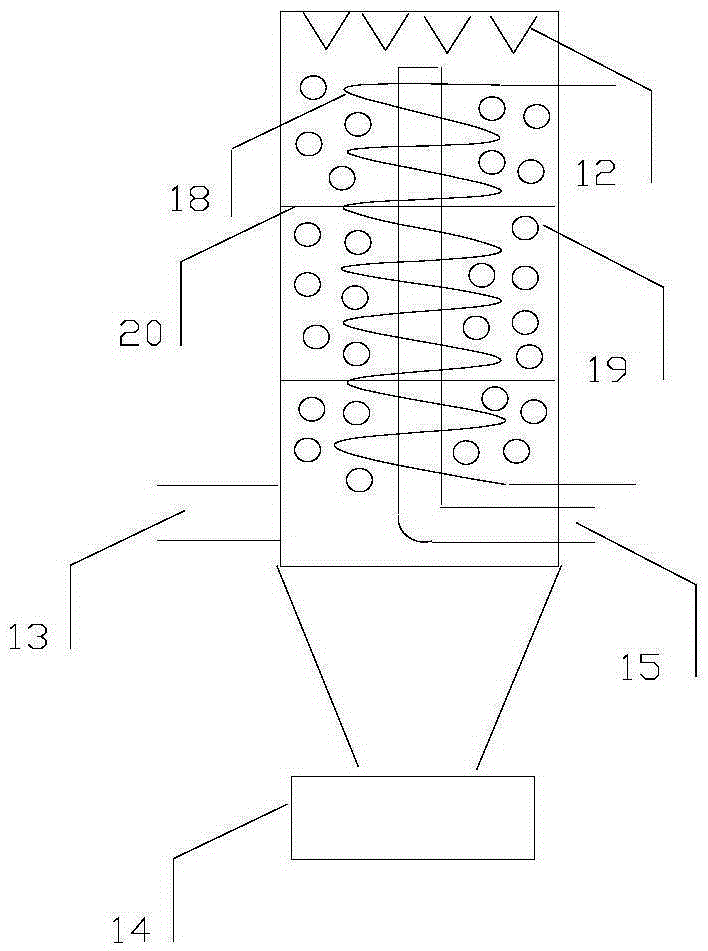

[0053] Put 0-0.2mm pulverized coal into the external heating type pyrolysis furnace (electric heating), raise the temperature to 600°C at a certain heating rate at room temperature (a certain amount of nitrogen gas is introduced into the gas distributor at the bottom of the heating furnace), and maintain a certain Time: While adding pulverized coal, feed circulating cooling water into the snake pipes in the first tar condensation tower and the second tar condensation tower, do not open the vacuum pump, and the pressure in the process is normal pressure. When the reaction is finished, measure and calculate the yield of pyrolysis semi-coke, tar, pyrolysis water and pyrolysis gas (see Figure 5 ). The tar that test obtains carries out gas chromatography-mass spectrometry analysis (results see Figure 6 and Figure 7 ).

Embodiment 2

[0055] The present invention provides a method for increasing the yield of low-rank coal pyrolysis coal tar. According to the same process as that of Example 1, the pyrolysis test and tar recovery are carried out on the coal of the same raw material. The difference is that the vacuum needs to be turned on, and the pressure is controlled to 80kPa, 60kPa, 40kPa and 20kPa respectively, and 4 tests are carried out respectively. After the test, the yields of pyrolysis semi-coke, tar, pyrolysis water and pyrolysis gas were measured and calculated (see Figure 5 ). The tar that test obtains carries out gas chromatography-mass spectrometry analysis (results see Figure 6 and Figure 7 ).

[0056] Depend on Figure 5 It can be seen that with the reduction of the pressure in the pyrolysis process and under the pyrolysis conditions with the presence of purge gas, the pyrolysis tar yield gradually increased. % tar yield increased more. Depend on Figure 6 and Figure 7 It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com