Fluidization heat accumulation type sludge low-temperature catalytic pyrolysis method and device thereof

A technology of catalytic pyrolysis and low-temperature catalysis, which is used in the pyrolysis treatment of sludge, waste heat treatment, vaporization of by-products, etc., can solve the problems of increasing the cost of sewage treatment plants, low degree of automation of equipment, and difficult to deal with odorous gases. Simple, reduce safety hazards and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

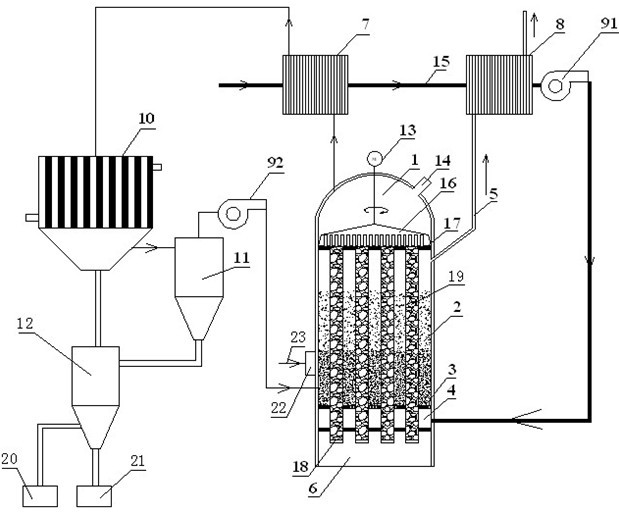

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Fluidized regenerative sludge low-temperature catalytic pyrolysis method, in this method can be used such as figure 1 The shown device, the method comprises the steps of:

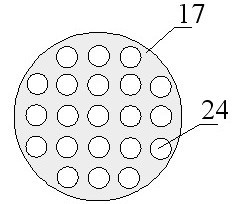

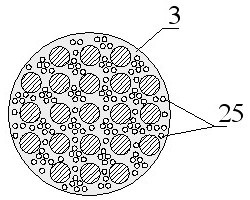

[0033] A. Sludge pyrolysis gas production: Add sludge into the preheating drying chamber 1, and the sludge is evenly distributed on the sieve plate 17 under the rotation of the homogenizing blade 16 set in the preheating drying chamber 1 above, enter the sludge catalytic pyrolysis reaction chamber 19 through the sieve holes 24 on the sieve plate 17, and the Na on the inner wall surface of the sludge catalytic pyrolysis reaction chamber 19 2 CO 3 or K 2 CO 3 A low-temperature pyrolysis reaction occurs under the action of the pyrolysis catalyst, and the sludge after the pyrolysis reaction forms a pyrolysis product, and the pyrolysis product enters the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com