Efficient and energy-saving heavy-magnesium water pyrolysis method

A high-efficiency and energy-saving technology for heavy magnesium hydrolysis, applied in magnesium carbonate and other directions, can solve the problems of failure to achieve large changes in production input and overall operating benefits, large thermal energy consumption, and low thermal efficiency, and achieve good industrial application prospects. , energy saving and emission reduction benefits, the effect of high thermal energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

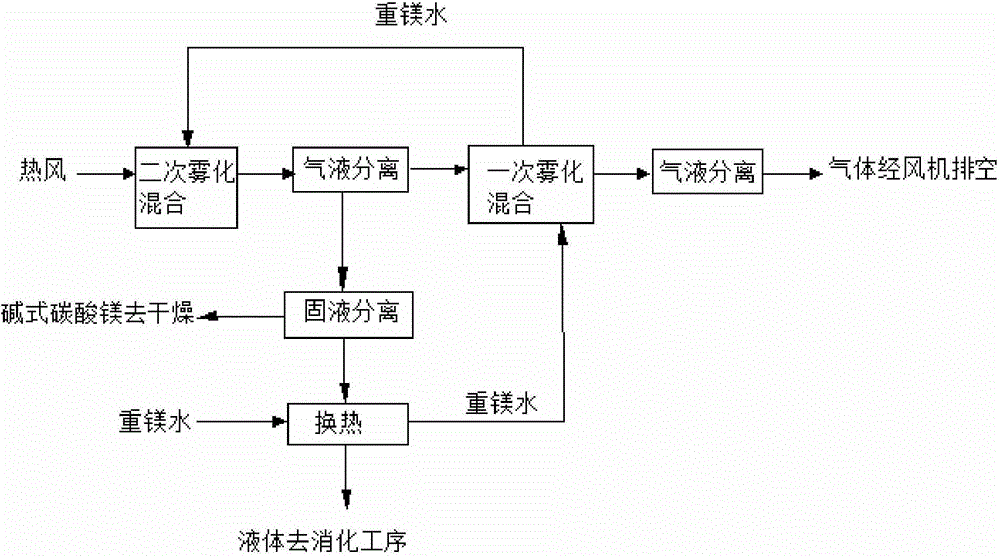

[0024] Such as figure 1 Shown, a kind of efficient and energy-saving heavy magnesium hydrolysis method specifically comprises the following steps:

[0025] (1) Indirect preheating of heavy magnesium water: replace the carbonized heavy magnesium water with a temperature of 20-25°C and a mass concentration of 8-15g / L (calculated as MgO) with the pyrolyzed 60°C pyrolysis solution. Indirect heat exchange of the heater, the first preheating, the temperature of the heavy magnesium water rises from 20-25°C to 30-35°C;

[0026] (2) Heavy magnesium water atomization preheating: The heavy magnesium water after indirect preheating is atomized in the primary atomization device, and the atomized particle size is controlled to 0.1-0.6 mm, and the hot moisture separated from the secondary atomization device Dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com