Preparation method and applications of inorganic flocculant adopting vermiculite mineral as raw material

An inorganic flocculant and flocculant technology, applied in the field of water pollution treatment, can solve the problems of high human and biological hazards, inability to reuse the treatment process, and increased water treatment costs, and achieve low price, easy access, and low treatment costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A kind of preparation method of the inorganic flocculant taking vermiculite mineral as raw material, comprises the following steps:

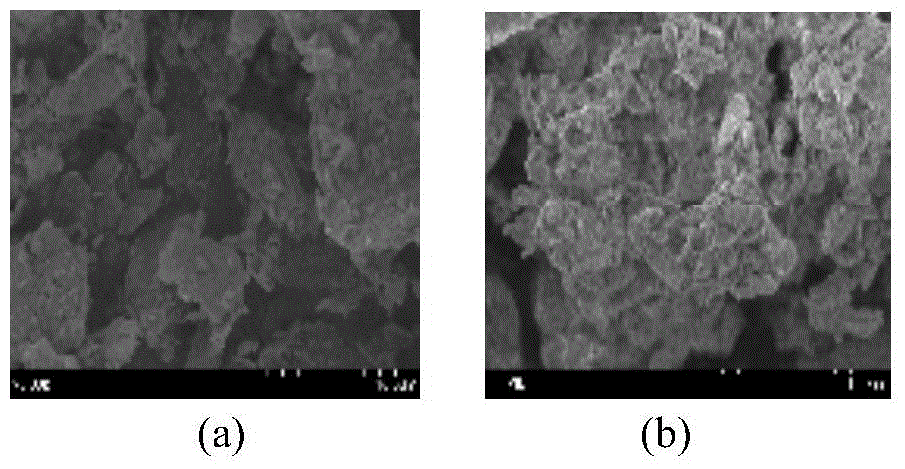

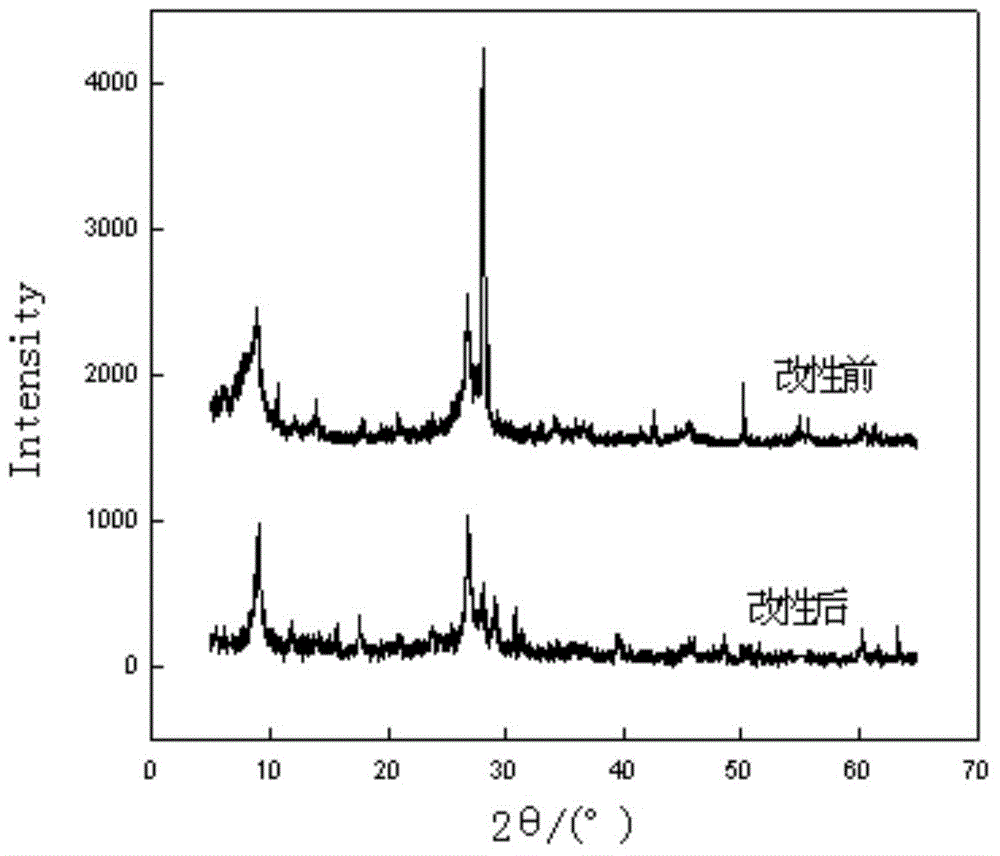

[0041] ⑴. Vermiculite is a layered structure of magnesium-containing hydroaluminosilicate secondary metamorphic minerals. It is natural, non-toxic and rich in minerals. After crushing, the specific surface area of vermiculite will increase, and the effective flocculation components such as silicon, iron, and aluminum can be released better after modification, so the raw materials should be crushed, and vermiculite with high metal iron and aluminum content should be selected. Stone, wherein the mass fraction of metal iron element is: 12-14%, the mass fraction of metal aluminum element is: 25-29%, and the vermiculite raw material is pulverized for 1-4min, so that the average particle size is 129.5-213.5μm;

[0042] (2) Mix the crushed vermiculite with an acid solution, the acid solution is sulfuric acid, hydrochloric acid or oxalic acid, ...

Embodiment 1

[0046] A kind of preparation method of the inorganic flocculant taking vermiculite mineral as raw material, comprises the following steps:

[0047] ⑴. Select vermiculite with high content of metallic iron and aluminum, wherein the mass fraction of metallic iron is 12%, and the mass fraction of metallic aluminum is 25%. Grind the vermiculite raw material for 1 min to make the average particle size 213.5 μm;

[0048] ⑵. Mix the crushed vermiculite with 10% hydrochloric acid solution, the mass ratio of vermiculite to hydrochloric acid solution is 0.7:1, stir the mixture vigorously until it becomes a paste, and heat it in a water bath at 25°C for 8 hours. Viscous slurry flocculant can be obtained.

Embodiment 2

[0050] A kind of preparation method of the inorganic flocculant taking vermiculite mineral as raw material, comprises the following steps:

[0051] ⑴. Select vermiculite with high content of metallic iron and aluminum elements, wherein the mass fraction of metallic iron is 13.6%, and the mass fraction of metallic aluminum is 27.1%. Grind the vermiculite raw material for 3 minutes to make its particle size 139.1 μm;

[0052] ⑵. Mix the crushed vermiculite with 40% sulfuric acid solution, the mass ratio of vermiculite to sulfuric acid solution is 1:1, stir the mixture vigorously until it becomes a paste, and heat it in a water bath at 75°C for 2 hours, that is Viscous slurry flocculant can be obtained;

[0053] ⑶. Add a certain quality of distilled water to the viscous slurry colloidal flocculant prepared in step ⑵. The mass ratio of colloidal flocculant to water is 1:5, then mix and filter to obtain a liquid flocculant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com