A system for producing basic magnesium carbonate by pyrolyzing heavy magnesium water

A technology of heavy magnesium water and magnesium carbonate, which is applied in the direction of magnesium carbonate, can solve the problems of production input and overall operating benefits that have not been greatly changed, high comprehensive costs, and low thermal efficiency, so as to achieve good industrial application prospects and solve Easy to scale and block, high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

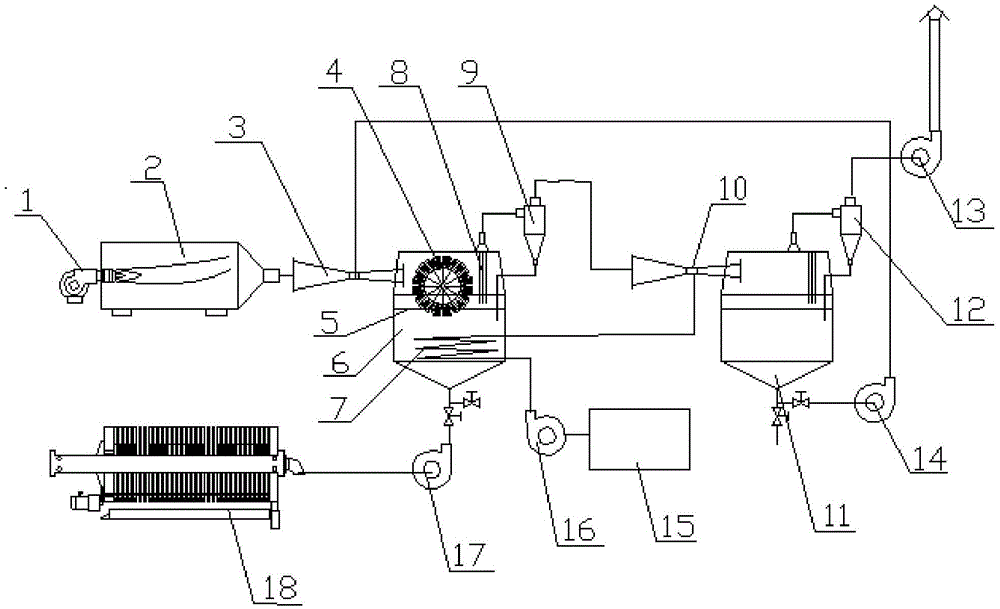

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0022] Such as figure 1 As shown, a system for producing basic magnesium carbonate by pyrolyzing heavy magnesium water mainly includes a burner 1, a hot blast stove 2, and a pyrolysis tank 6. The burner 1 is connected with the hot blast stove 2, and the hot blast stove 2 is connected with a venturi- The first-level atomizer 3 is connected by a pipeline, and the Venturi first-level atomizer 3 is connected with the pyrolysis tank 6, and the top of the pyrolysis tank 6 is connected by a pipeline near the top of the cyclone separator 9, and the The bottom of the pyrolysis tank 6 is connected to the filter press pump 17 through a pipeline, and the filter press pump 17 is connected to the filter press 18 through a pipeline. The inside of the pyrolysis tank 6 is provided with a preheating coil 7, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com