Method for low temperature preparation of basic magnesium carbonate crystal with assistance of absolute ethanol

An anhydrous ethanol, magnesium carbonate technology, applied in magnesium carbonate, crystal growth, chemical instruments and methods, etc., can solve the problems of reduction of high-quality mineral resources, waste of resources, etc., and achieve the effects of reducing preparation cost, simple operation and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

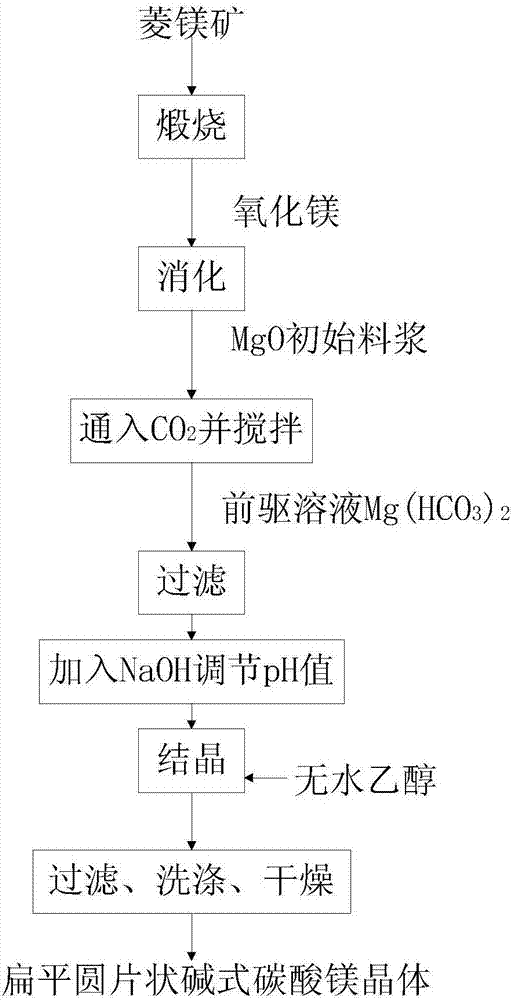

[0054] A method for preparing basic magnesium carbonate crystals at low temperature with the assistance of absolute ethanol, the process flow diagram is shown in figure 1 , including the following steps:

[0055] (1) Calcined magnesite

[0056] The magnesite was calcined at 750°C for 3.0 hours, so that the decomposition rate of magnesite reached 99%, and active magnesium oxide was obtained. The activity was detected by the citric acid method, and the discoloration time was 30s;

[0057] Grinding the activated magnesium oxide to -74 μm to obtain activated magnesium oxide powder;

[0058] (2) Digest and prepare Mg(OH) 2 suspension

[0059] Using the obtained activated magnesia powder as raw material, add deionized water at 90°C, fully stir to prepare MgO initial slurry; wherein, according to the mass ratio, activated magnesia powder: deionized water = 1:40;

[0060] Put the initial slurry of MgO in a constant temperature water bath at 60°C, stir for 3.5 hours, and air-cool t...

Embodiment 2

[0068] A method for preparing basic magnesium carbonate crystals at low temperature under the assistance of dehydrated alcohol, comprising the steps of:

[0069] (1) Calcined magnesite

[0070] The magnesite was calcined at 700°C for 3.0 hours, so that the decomposition rate of magnesite was 98%, and active magnesium oxide was obtained. The activity was detected by the citric acid method, and the discoloration time was 28s;

[0071] The activated magnesium oxide is pulverized into activated magnesium oxide powder with a particle size of -72 μm;

[0072] (2) Digest and prepare Mg(OH) 2 suspension

[0073] Using the obtained activated magnesia powder as raw material, add deionized water at 70°C, fully stir to prepare MgO initial slurry; wherein, according to the mass ratio, activated magnesia powder: deionized water = 1:50;

[0074] Put the initial MgO slurry in a constant temperature water bath at 55°C, stir for 5.0 h, and air cool to room temperature to obtain Mg(OH) 2 sus...

Embodiment 3

[0081] A method for preparing basic magnesium carbonate crystals at low temperature under the assistance of dehydrated alcohol, comprising the steps of:

[0082] (1) Calcined magnesite

[0083] The magnesite was calcined at 800°C for 1.0h, so that the decomposition rate of magnesite was 99%, and active magnesium oxide was obtained. The activity was detected by the citric acid method, and the discoloration time was 30s;

[0084] Grinding activated magnesium oxide to activated magnesium oxide powder with a particle size of -70 μm;

[0085] (2) Digest and prepare Mg(OH) 2 suspension

[0086] Using the obtained activated magnesia powder as raw material, add deionized water at 100°C, fully stir to prepare MgO initial slurry; wherein, according to the mass ratio, activated magnesia powder: deionized water = 1:12;

[0087] Put the initial MgO slurry in a constant temperature water bath at 65°C, stir for 1.0 h, and air cool to room temperature to obtain Mg(OH) 2 suspension;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com