Method for recycling industrial waste salt

An industrial waste salt and resource recycling technology, which is applied in chemical instruments and methods, solid waste removal, inorganic chemistry, etc. The problem of high cost can reduce corrosion and environmental pollution, reduce energy consumption, and reduce corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

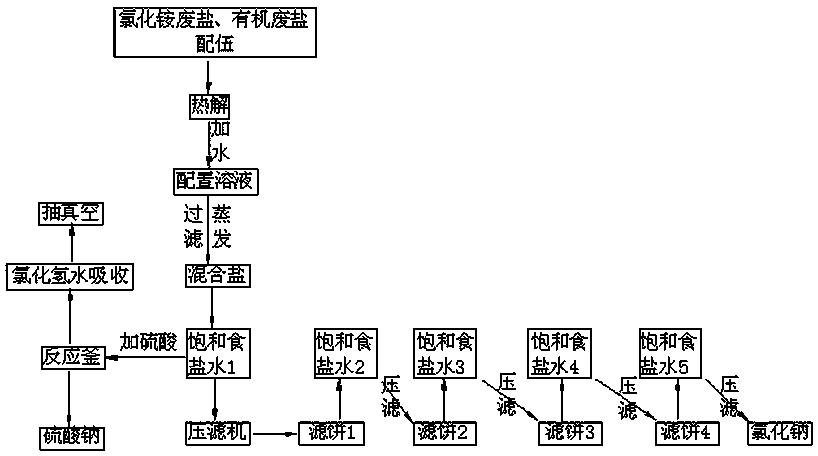

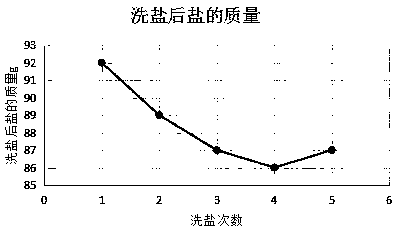

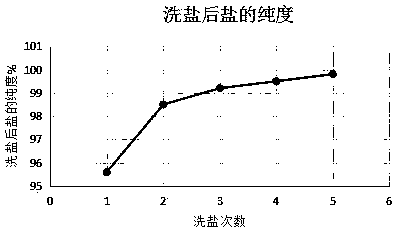

[0016] Embodiments of the present invention: as figure 1 As shown, a method for resource recovery of industrial waste salt includes the following steps: (1) Take waste salt containing high ammonium chloride and organic waste salt for compatibility, and the ratio of the two is determined by pyrolysis test, so that The pyrolysis temperature is 300-350°C, and the ratio of ammonium chloride waste salt to organic waste salt in this example is 3:2; (2), take 300KG ammonium chloride waste salt and 200KG organic waste salt and mix them into In an incinerator, pyrolyze at 350°C for 2 hours to remove organic matter; (3), cool down, weigh 300KG of the waste salt after pyrolysis, add 1200L of water and stir to dissolve to prepare a solution; (4), filter the solution , to obtain the clear liquid, evaporate to obtain 270KG of mixed salt solid; (5), prepare 5 cans of 500L saturated sodium chloride solution, the serial numbers are 1, 2, 3, 4, 5 in sequence, weigh the same batch of mixed salt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com