Patents

Literature

38results about How to "Raise the pyrolysis temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosetting resin composition and use

InactiveCN101481490AImprove heat resistanceExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsGlass fiberTetrabromobisphenol A

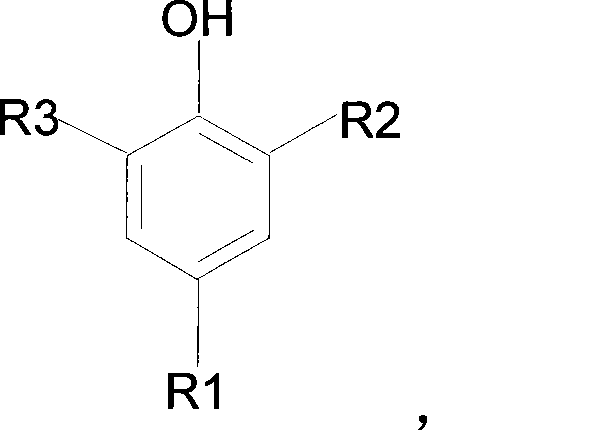

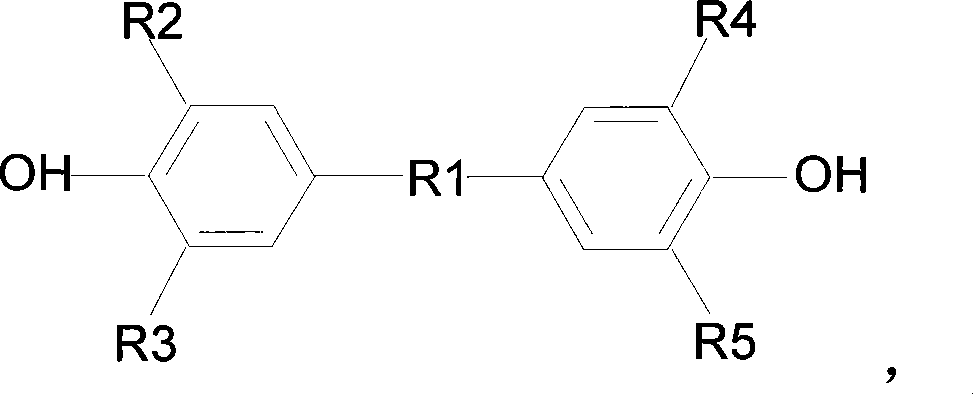

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

Thermosetting resin composition and application

The invention discloses a thermosetting resin composition, which comprises the following components: bifunctional or multifunctional epoxy resin, styrene-maleic anhydride copolymer SMA as a curing agent with styrene / maleic anhydride molar ratio of 5-12:1, low-bromine or high-bromine BPA type epoxy resin or tetrabromo bisphenol A as a fire retardant, an accelerator and a solvent. The resin composition after curing has quite low dielectric property, higher heat reliability and better toughness, has quite low dielectric constant and dielectric loss coefficient, high Td, better toughness and excellent PCB processability with a copper-clad plate made of glass fiber cloth and other reinforcing materials, is suitable for manufacturing a copper-clad plate and a semi-cured plate for PCB, and can also be used in common application of the epoxy resin, such as molding resin, composite materials for buildings, automobiles and aviation, and the like.

Owner:ITEQ DONGGUAN

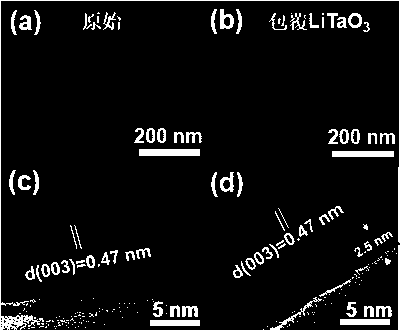

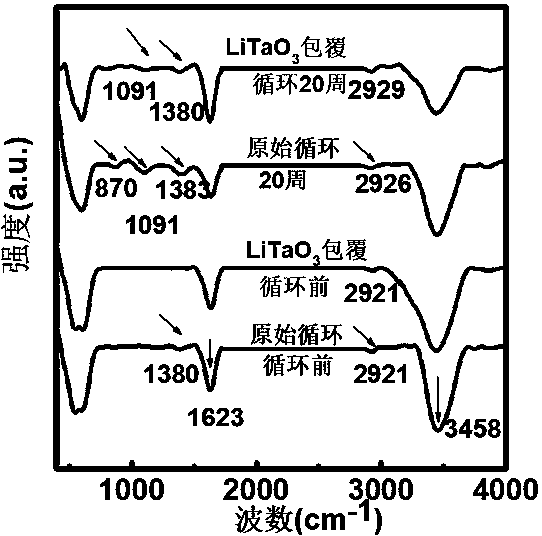

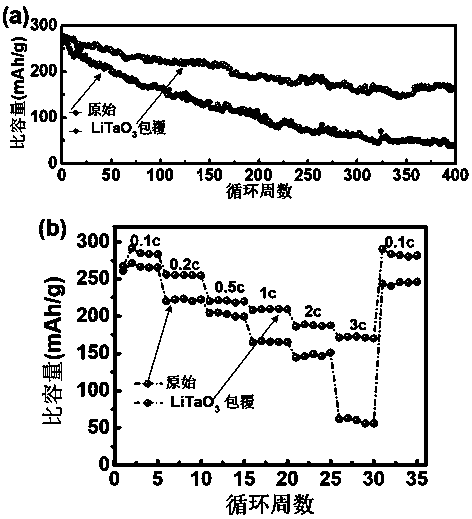

Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

PendingCN109921000AEasy to operateGood repeatabilityCell electrodesSecondary cellsBarium titanatePotassium

The invention provides a lithium ion battery anode material coated with piezoelectric material on the surface and a preparation method thereof. The surface of the battery anode material is coated witha layer of piezoelectric material with piezoelectric effect; the piezoelectric material comprises any one or more of barium titanate, lithium niobate, sodium niobate, lithium tantalite, sodium-potassium metaniobate and barium-strontium metaniobate with piezoelectric effect. The piezoelectric characteristic of the piezoelectric material is utilized to realize a coating modification function for the anode active materials so as to ensure that the volume phase structures of the anode active materials are not influenced and damaged, the growth of solid-electrolyte interface membranes is suppressed, and the diffusion speeds of active material-coating layer interface lithium ions are improved, thereby effectively improving the structure stability and electrochemical cycle performance of the lithium ion battery anode material, improving the pyrolysis temperature of the anode material and then enhancing the safety performance of the lithium ion batteries in the using process.

Owner:HENAN UNIVERSITY

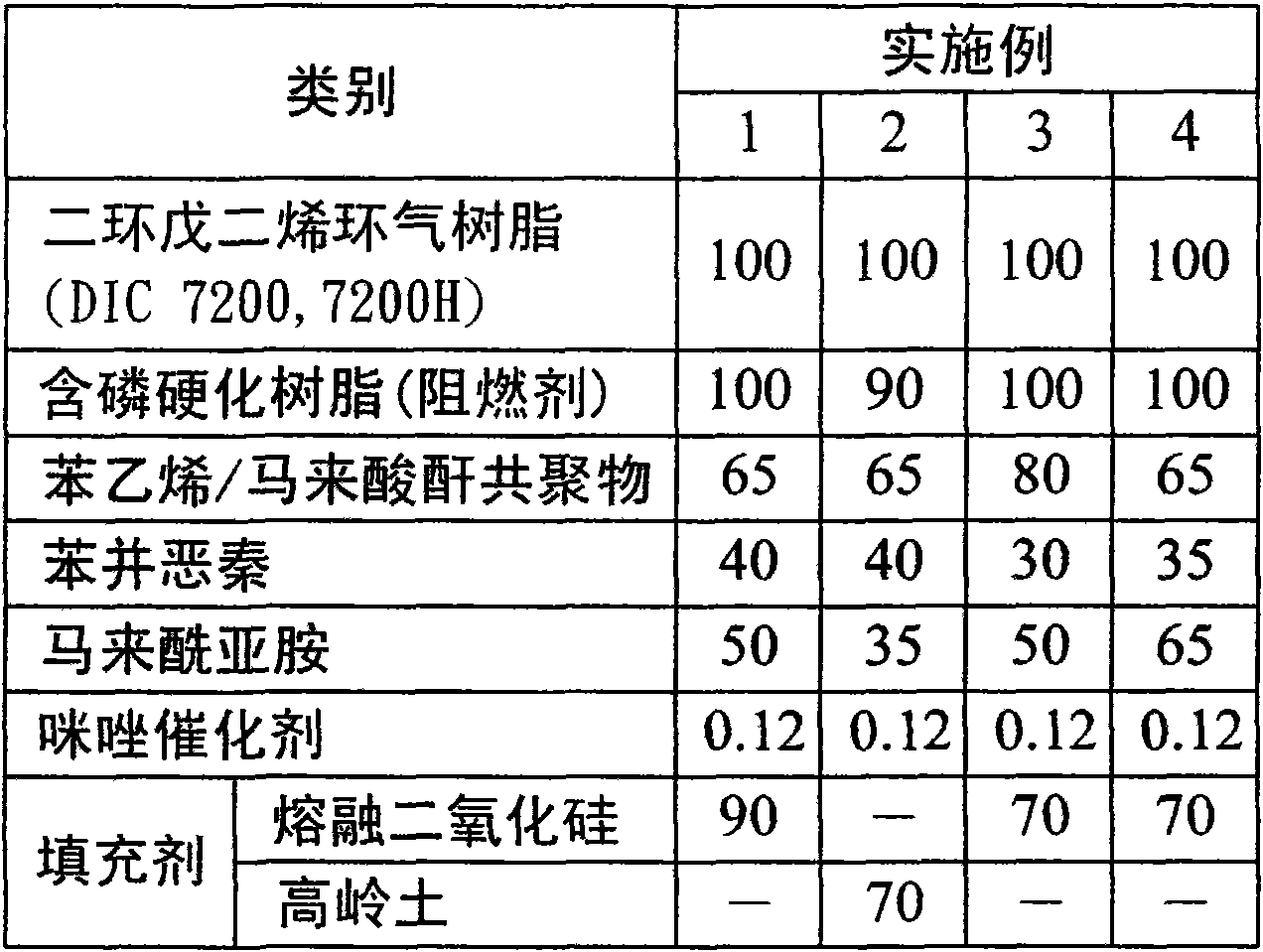

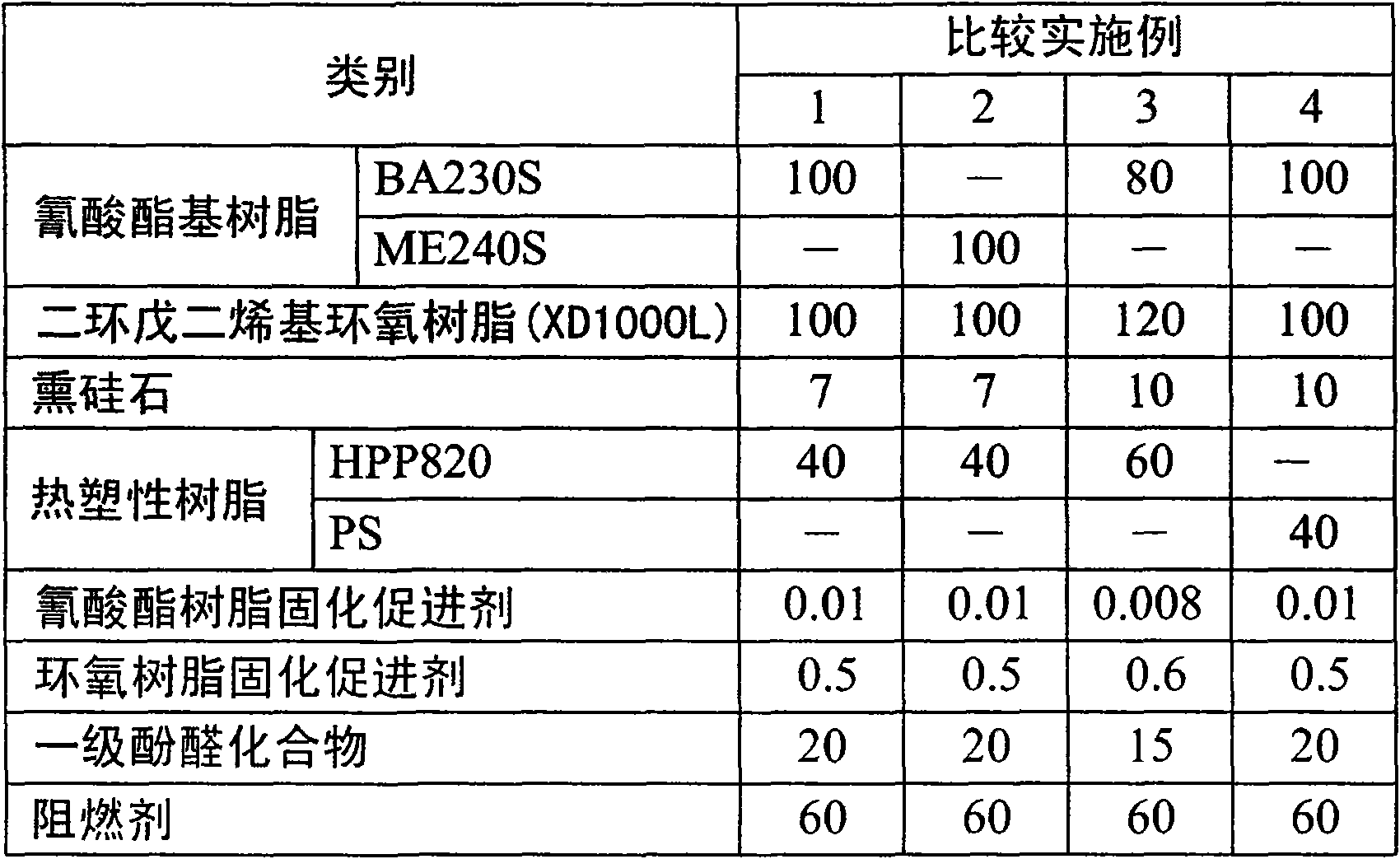

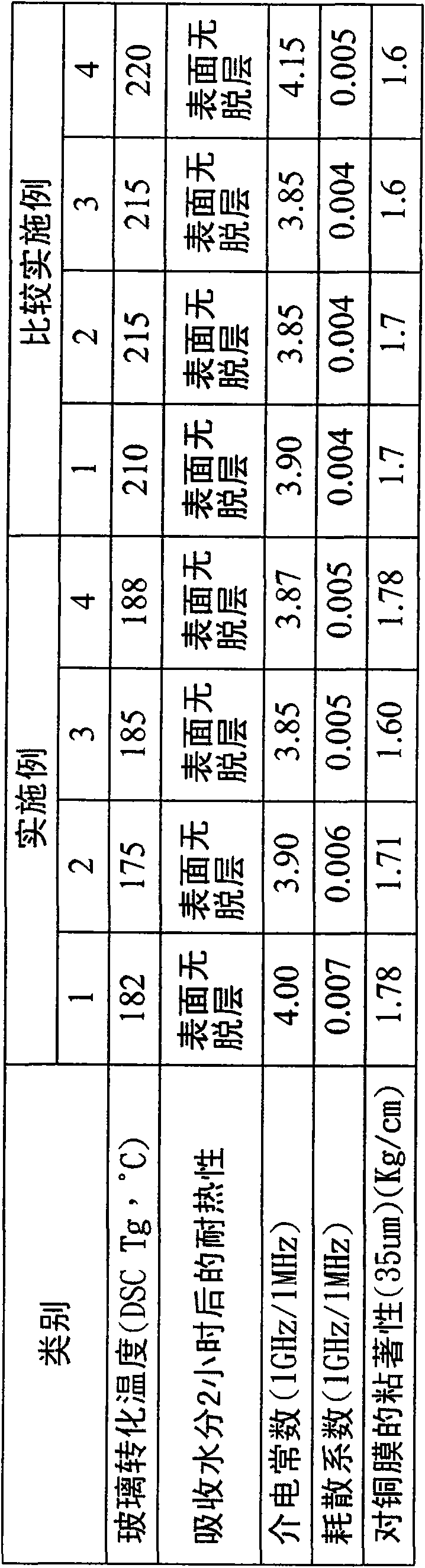

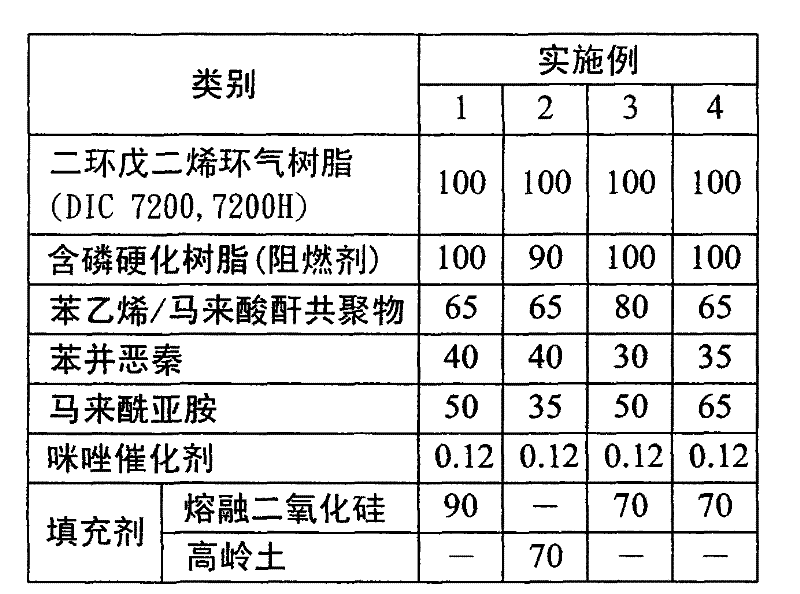

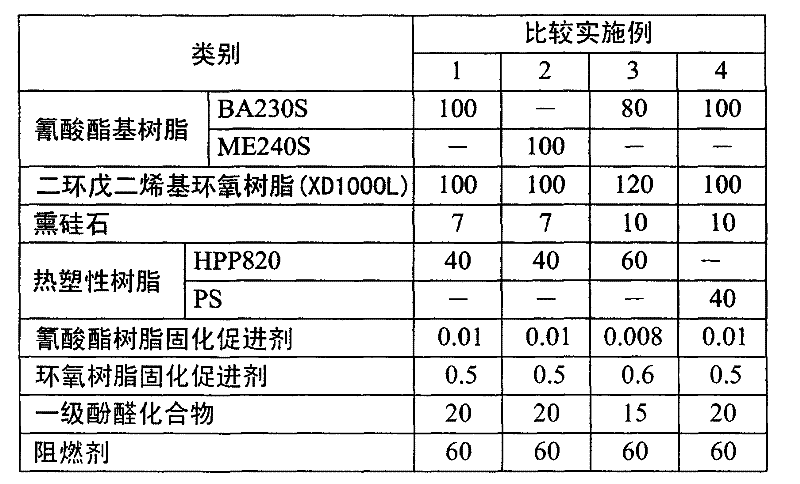

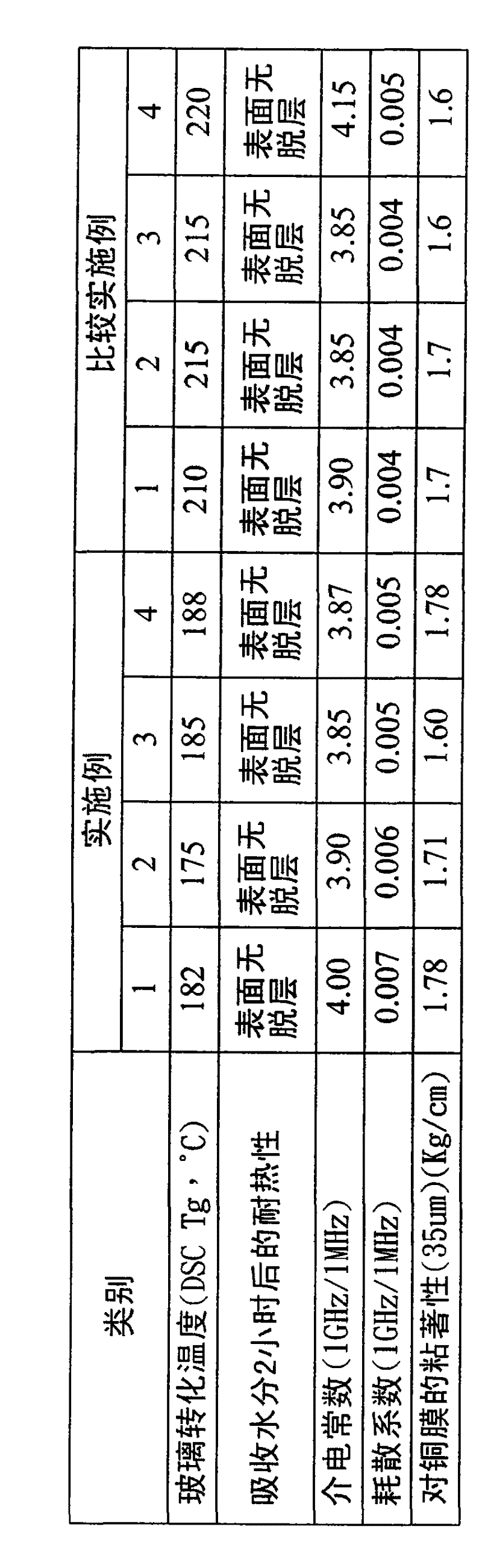

Composition of thermosetting resin and copper foil laminated plate

ActiveCN101942178ASufficient flame resistanceRaise the pyrolysis temperatureMetal layered productsHalogenMaleic anhydride

The invention relates to composition of a thermosetting resin. The thermosetting resin comprises dicyclopentadiene epoxy resin, benzoxazine, maleimide, styrene / maleic anhydride copolymer, filler, flame retardant and imidazole accelerant. The thermosetting resin is used for a high-speed transmission copper foil laminated plate, has the dielectric properties of low dielectric constant and low dissipation factor, and can be used for a high-speed signal transmission copper foil laminated plate. In addition, the thermosetting resin does not contain halogens, thereby having the advantage of environmental protection.

Owner:ELITE MATERIAL

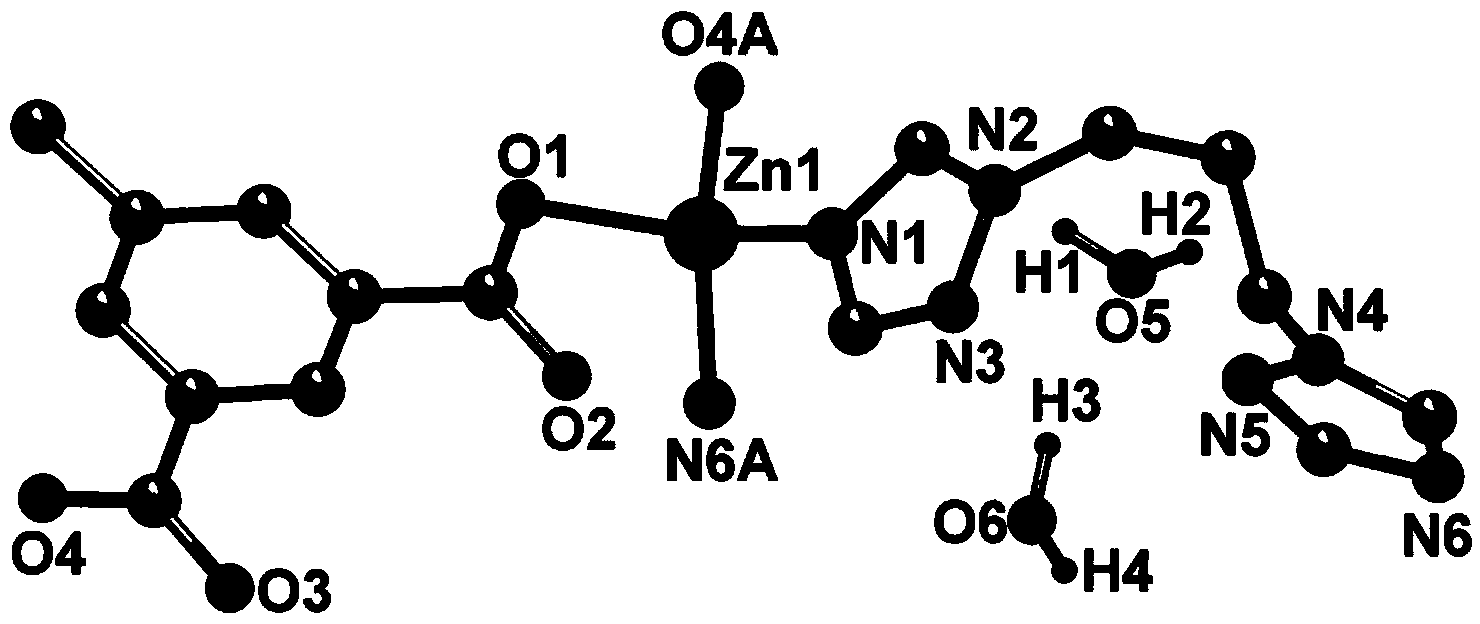

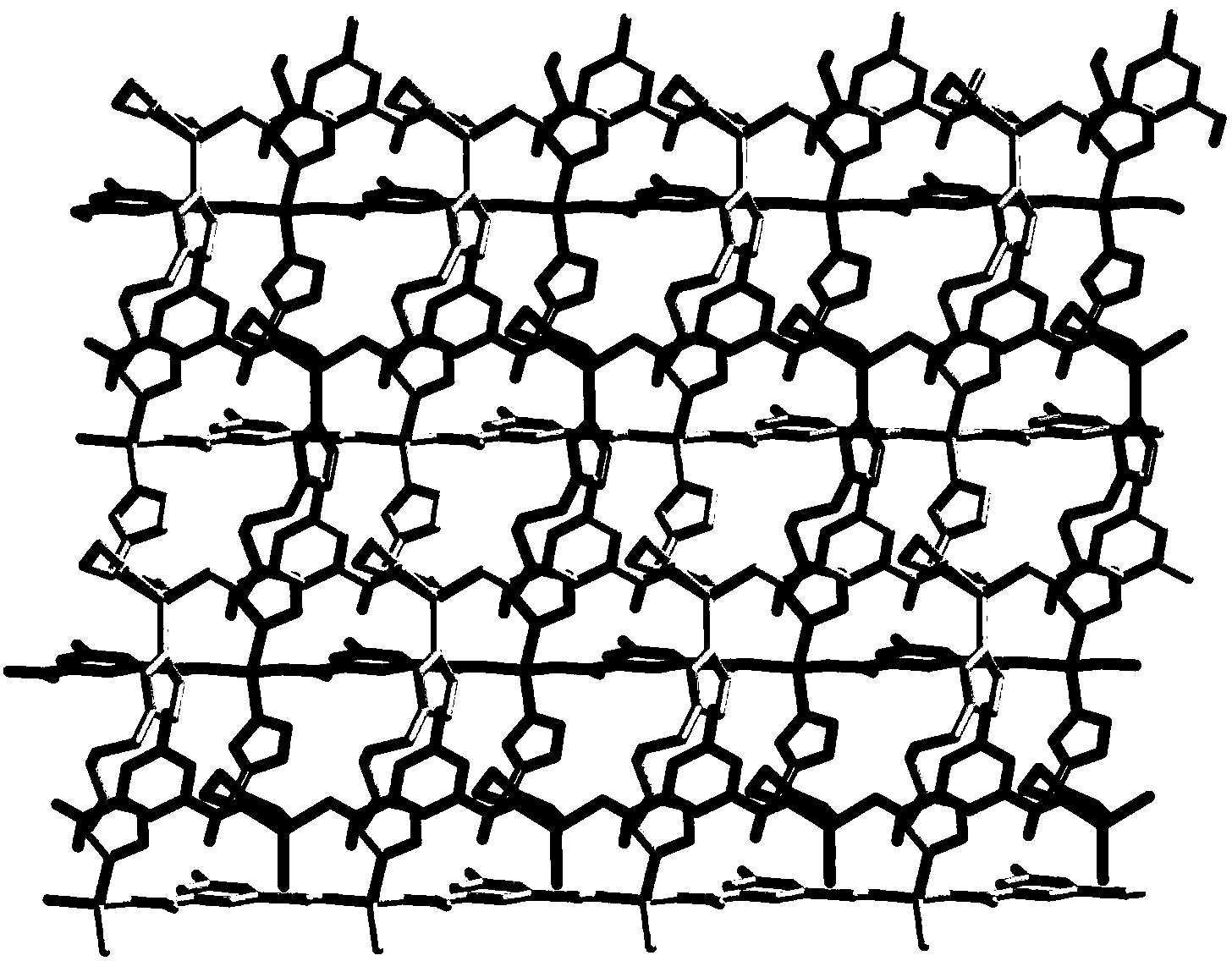

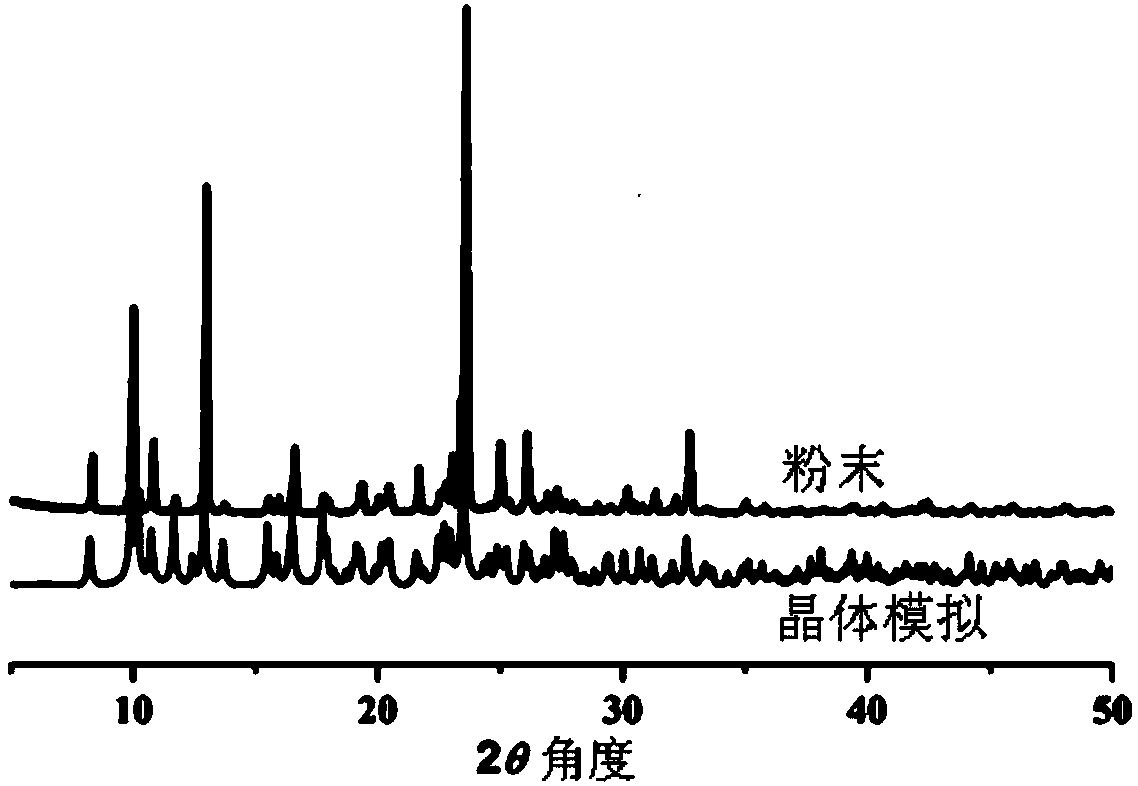

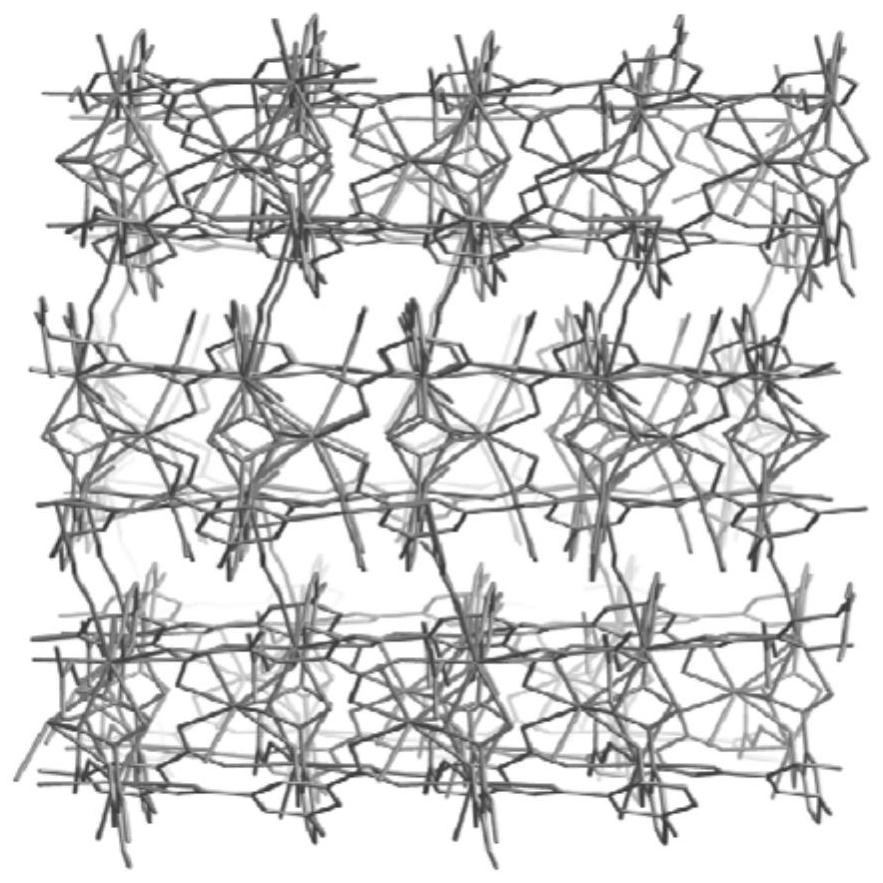

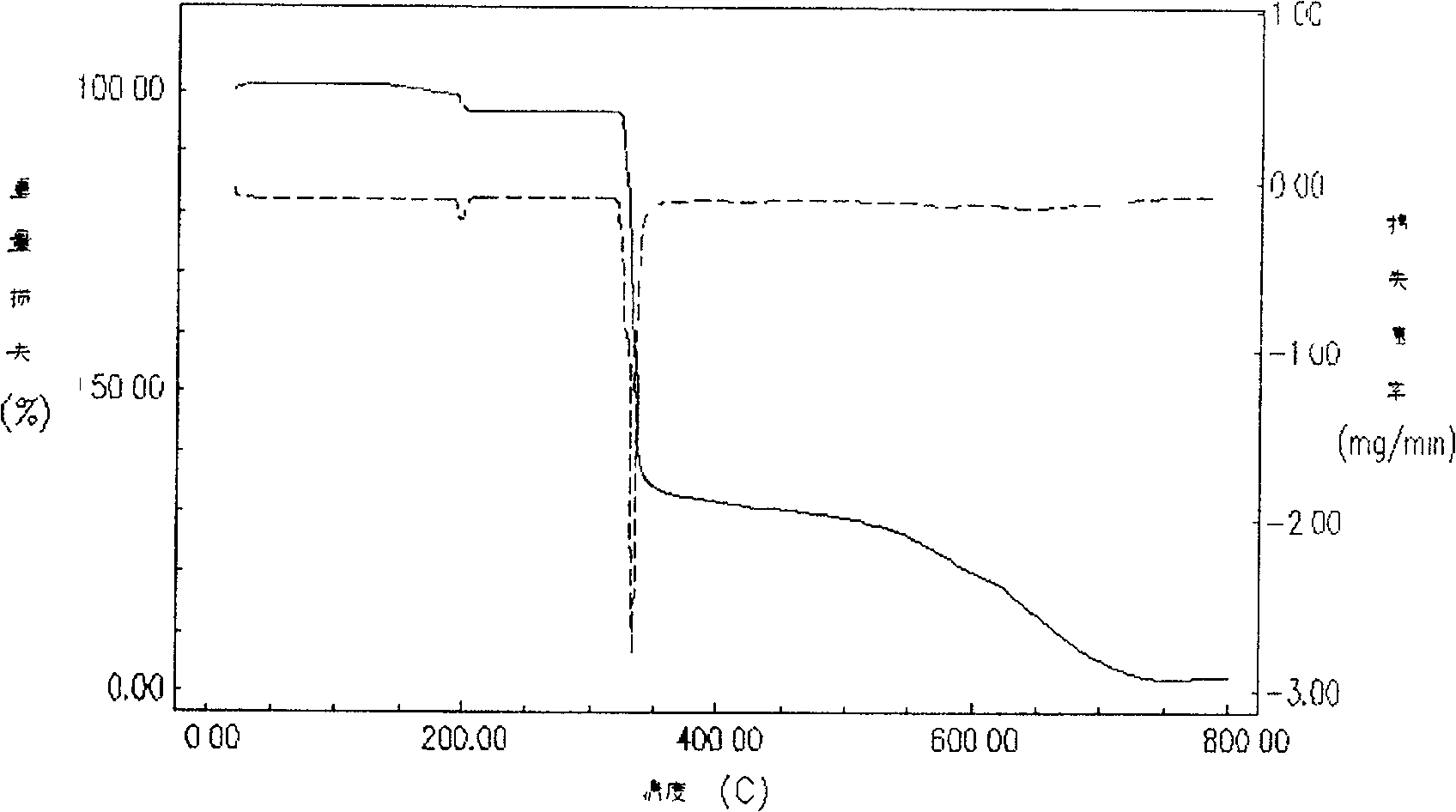

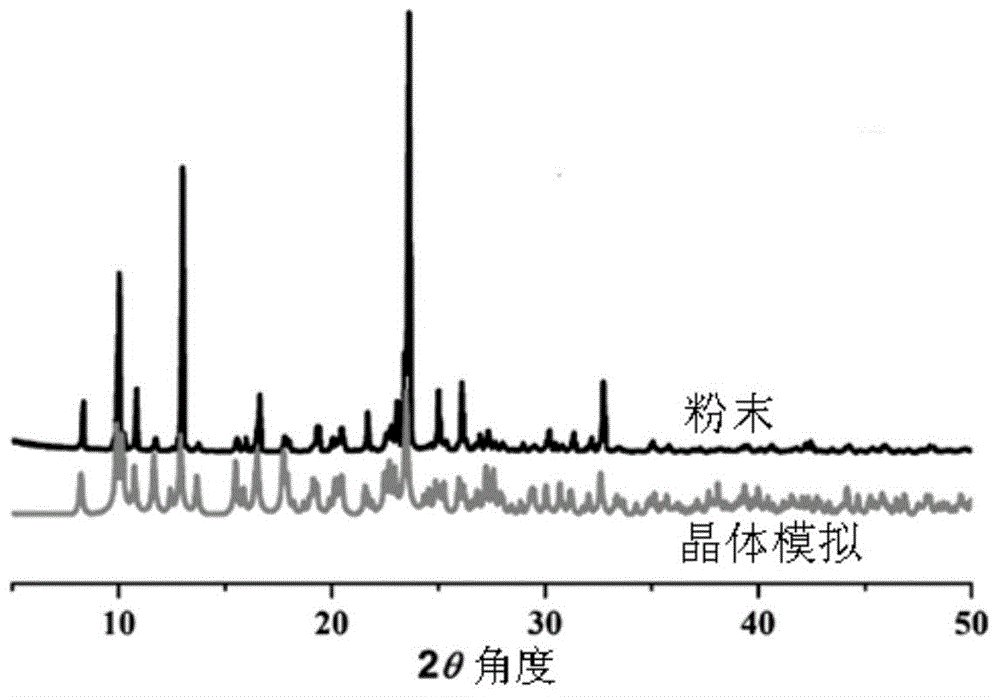

Novel triazole fluorescent coordination polymer as well as preparation method and application thereof

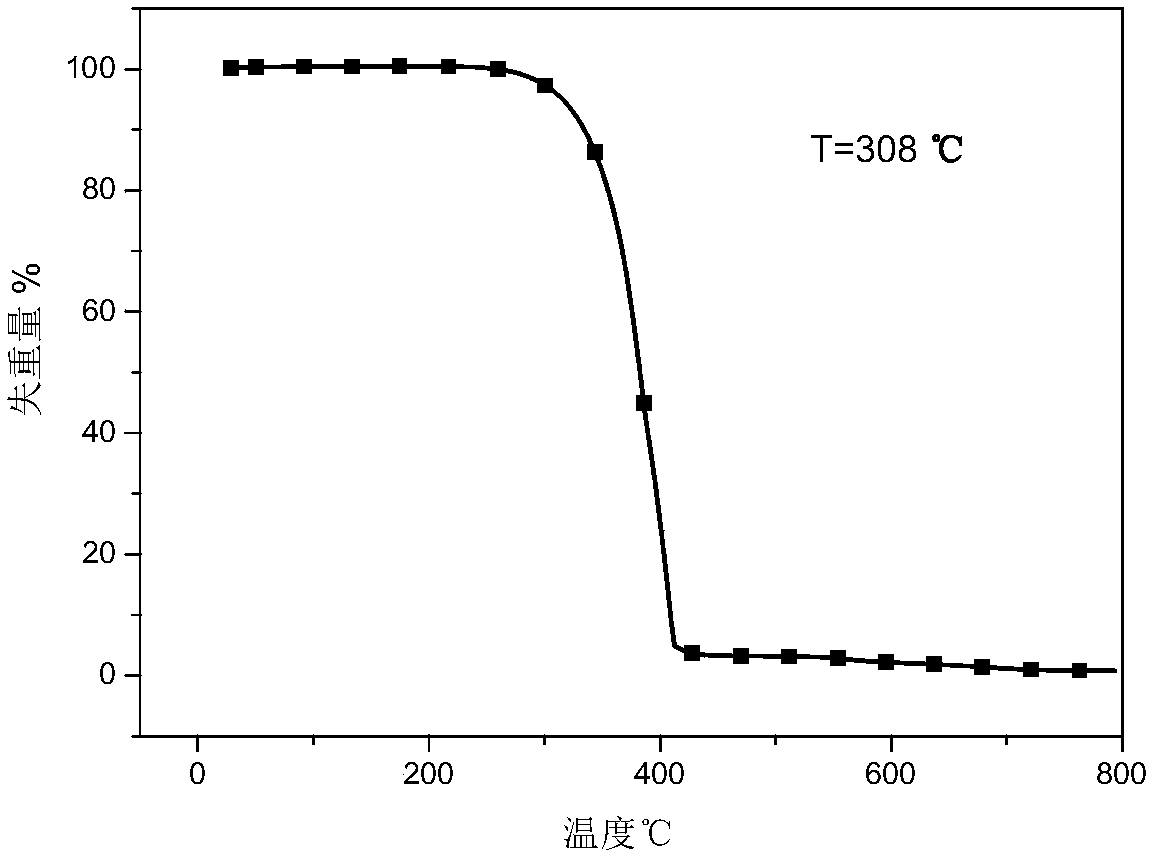

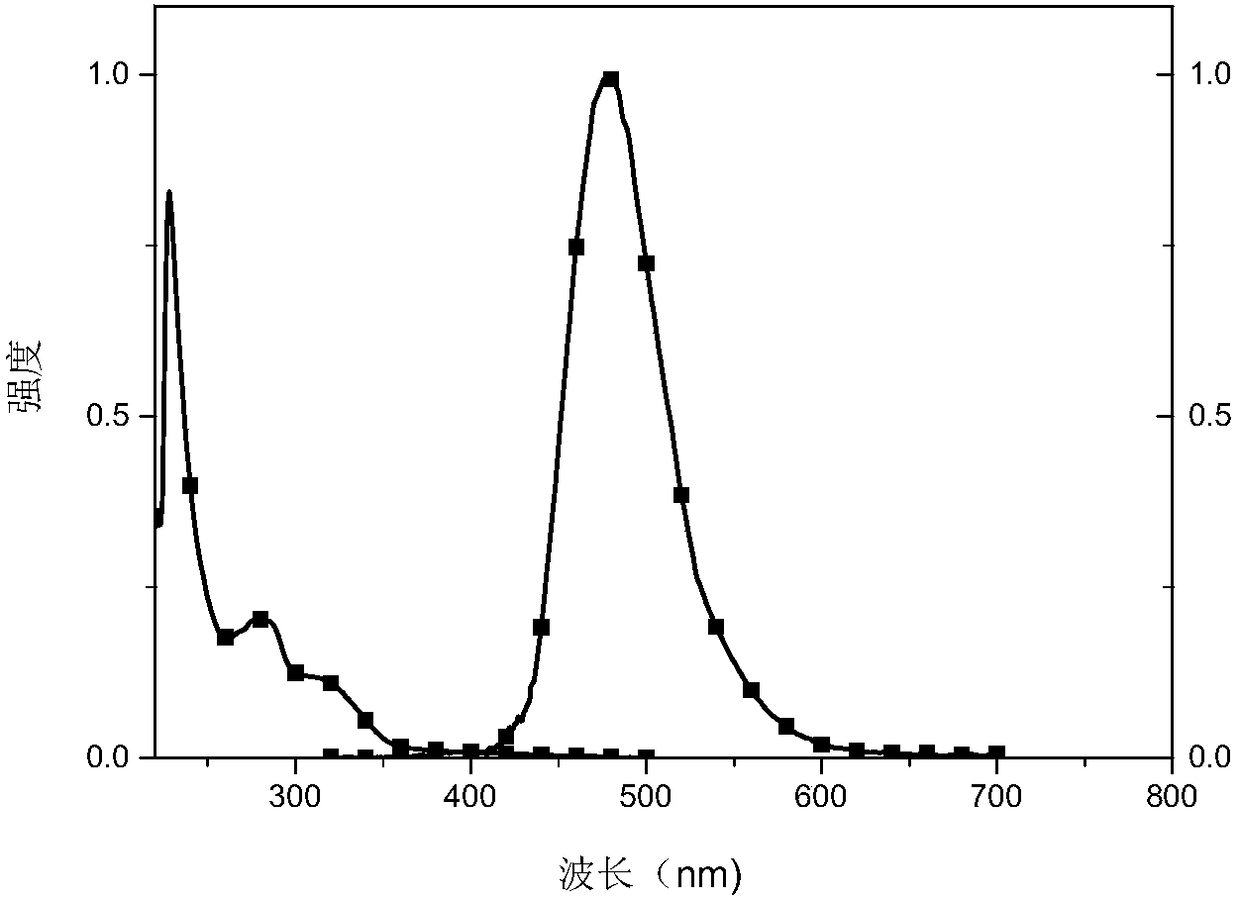

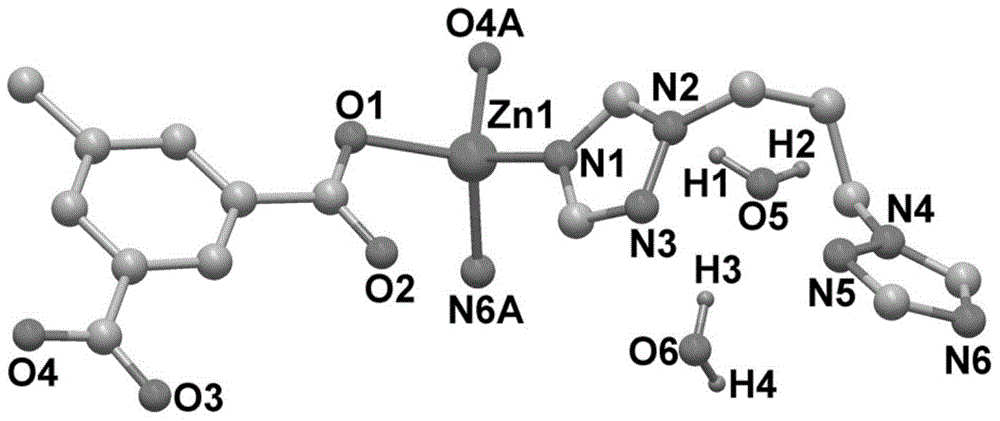

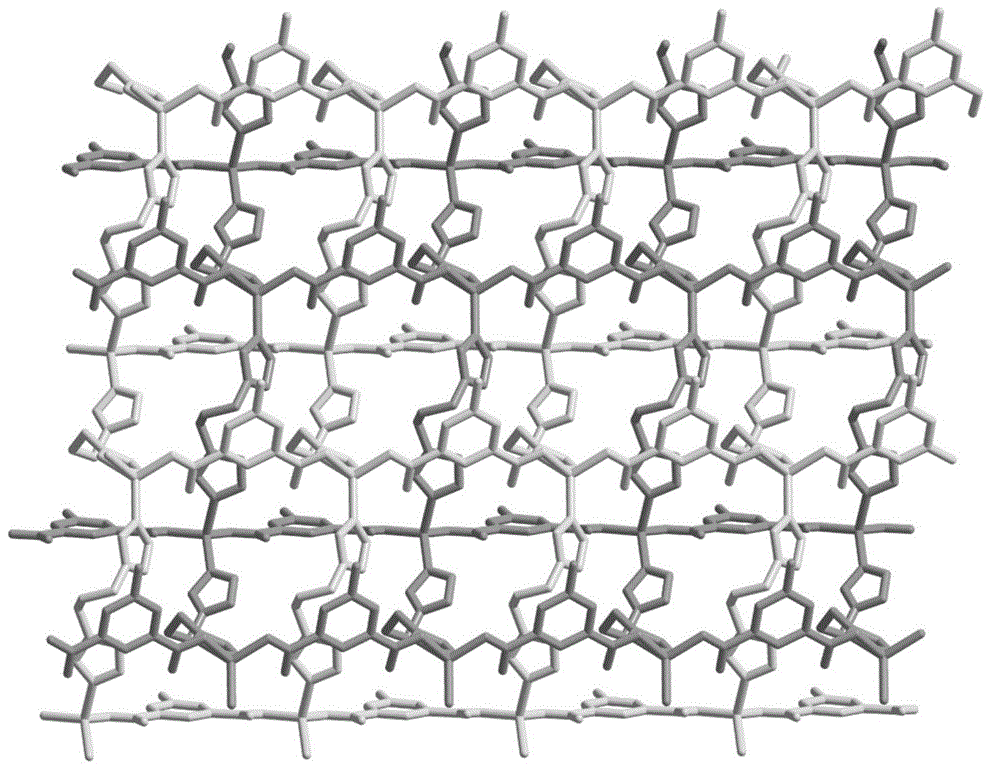

InactiveCN103588797AGood thermal stabilityRaise the pyrolysis temperatureGas discharge lamp usageFluorescence/phosphorescenceFluorescenceOrganic synthesis

The invention discloses a novel triazole fluorescent coordination polymer and a preparation method and application thereof, and belongs to the technical field of organic synthesis. The chemical formula of the novel triazole fluorescent coordination polymer is Zn(C9H6O4)(C7H10N6).(H2O)2, the novel triazole fluorescent coordination polymer belongs to monoclinic crystal systems and has a space group of P21 / c(No.14), and has cell parameters: alpha is equal to gamma and is equal to 90 degrees, and beta is equal to 110.9890 (10) degrees; the novel triazole fluorescent coordination polymer uses Zn (OAc)2.2H2O, 5-methyl isophthalic acid and 1,3-bis(1, 2, 4-triazolo)-propane as reactants, and is prepared by a hydrothermal method. The novel triazole fluorescent coordination polymer is good in thermal stability and high in luminous intensity, is a new product synthesized in a laboratory, and is simple in preparation method and wide in application.

Owner:HUAINAN NORMAL UNIV

Preparation method of high-purity aluminum oxide for growth of sapphire monocrystalline

InactiveCN102863000ARaise the pyrolysis temperatureLow pyrolysis temperatureAluminium oxide/hydroxide preparationSingle crystalAmmonia gas

The invention relates to a preparation method of a high-purity aluminum oxide, in particular to a preparation method of high-purity aluminum oxide for growth of sapphire monocrystalline. The method includes: grinding high-purity ammonium aluminum sulfate to obtain ammonium aluminum sulfate precursor powder uniform in particle size, heating according to different temperature sections, pyrolyzing to remove by-products, and sintering to obtain high-purity aluminum oxide uniform in particle size. According to the method, the high-purity ammonium aluminum sulfate is ground to obtain ammonium aluminum sulfate raw material powder, dewatering is completed at a low temperature, ammonia gas is removed at a moderate temperature, the temperature is further increased to enable the raw materials to be decomposed completely, and the high-purity aluminum oxide is obtained by means of sintering at 1000-1050 DEG C. The aluminum oxide prepared by the method is low in pyrolysis temperature and high in purity, tail gases such as SO3 and NH3 can be recovered directly, and consequently environment pollution is reduced, by-products are used reasonably, and production cost is reduced.

Owner:ZHEJIANG ORIENT CRYSTAL OPTICS

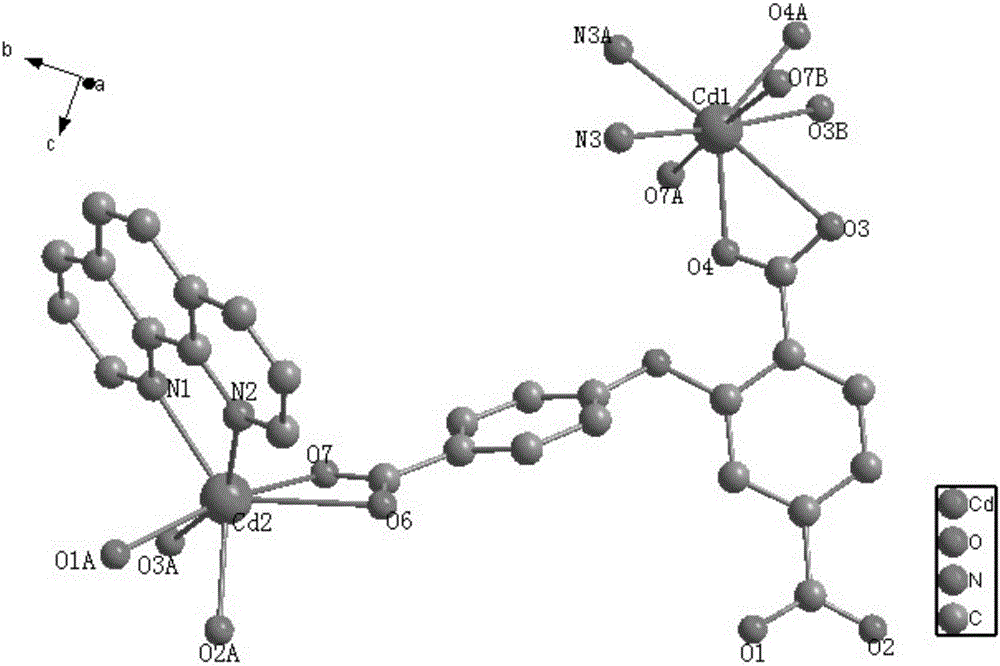

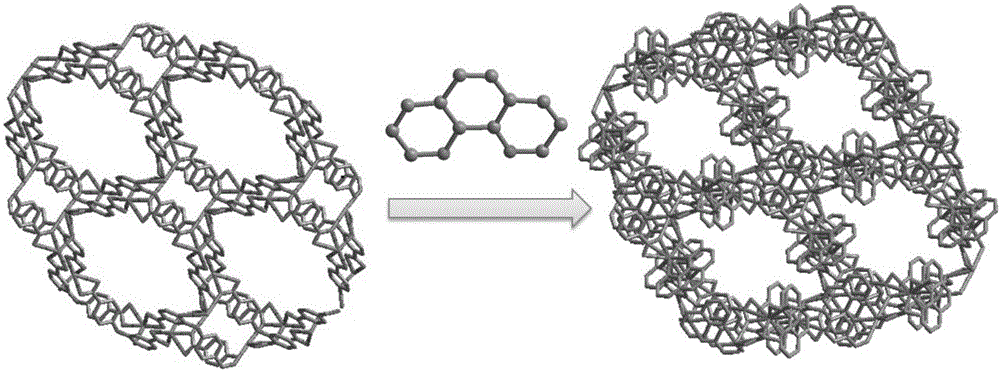

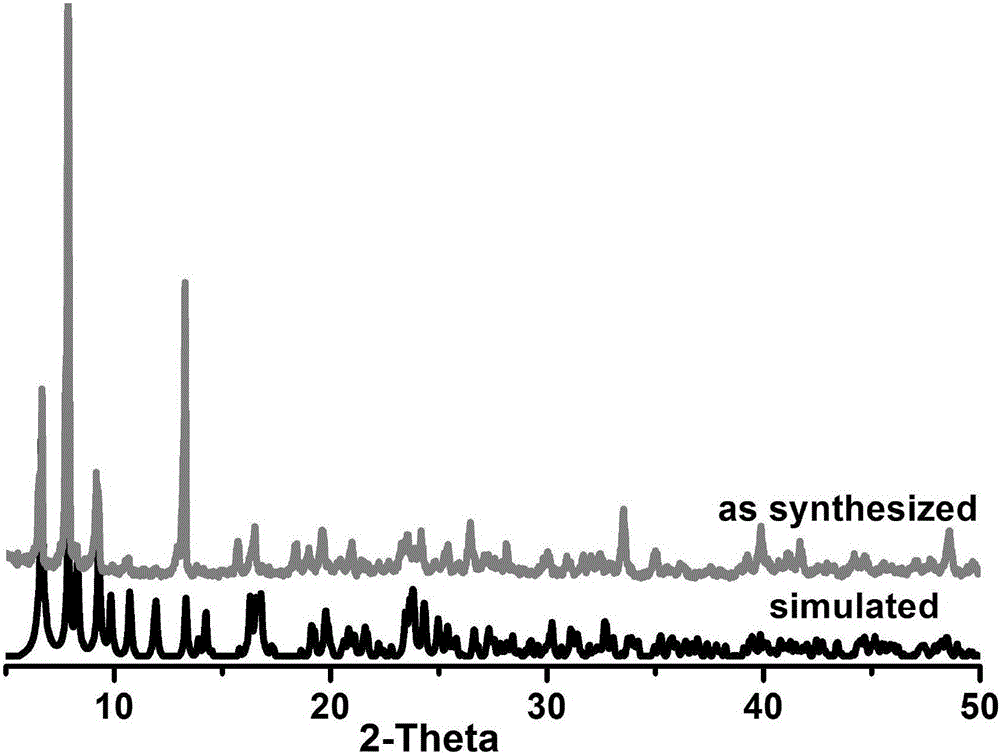

V-shaped triacid porous fluorescence coordination polymer, and preparation method and application thereof

ActiveCN106008568ASimple manufacturing methodHigh purityFluorescence/phosphorescenceLuminescent compositionsPorositySpace group

The invention discloses a porous fluorescence coordination polymer constructed by a V-shaped triacid organic ligand, and a preparation method and an application thereof. The chemical formula of the polymer is [Cd1.5(cia)(phen)1.5]n, the system of the polymer is a monoclinic system, and the space group of the system is a C2 / c space group, wherein cia is 2-(4-carboxylate benzoxy)terephthalic acid with a V-shaped skeleton structure, and phen is phenanthroline. The polymer is prepared through a solvothermal technology, and has a three-dimensional porous structure, and the porosity reaches 33%; the polymer has good thermal stability and high fluorescence intensity, and clear blue light and pure color can be determined from a CIE map; and the polymer also can be used to detect potassium dichromate guest molecules as a fluorescence probe. The preparation method has the advantages of simple process, easiness in enforcement, and realization of high purity and yield of crystals, and the polymer is simple to detect, has high selectivity and is a novel luminescent material.

Owner:SHAANXI UNIV OF SCI & TECH

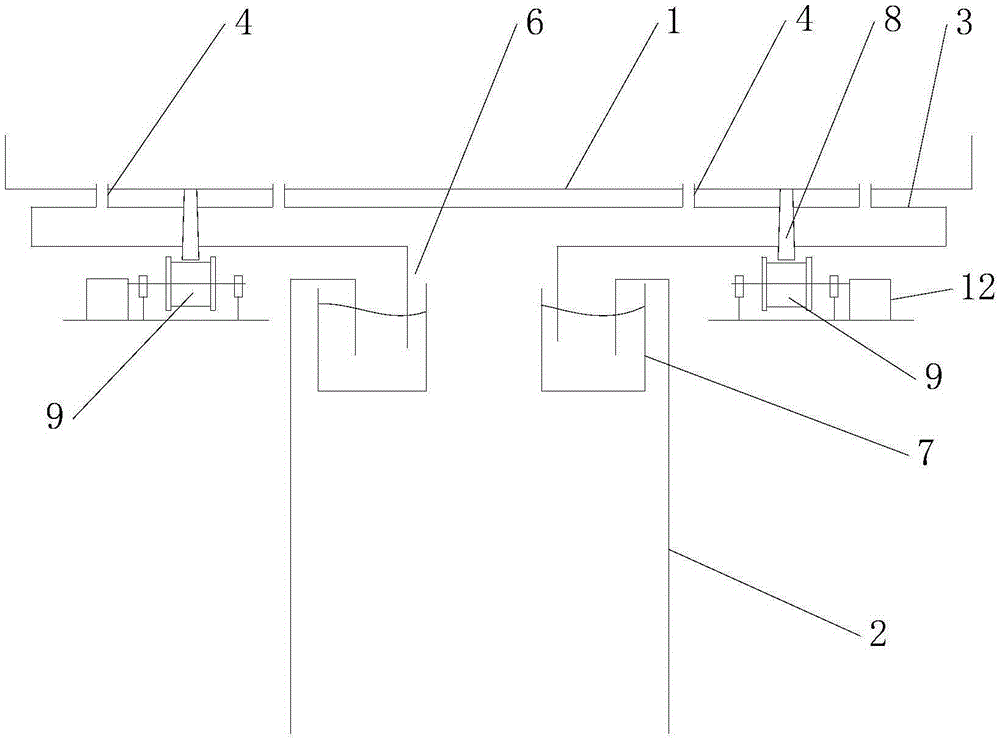

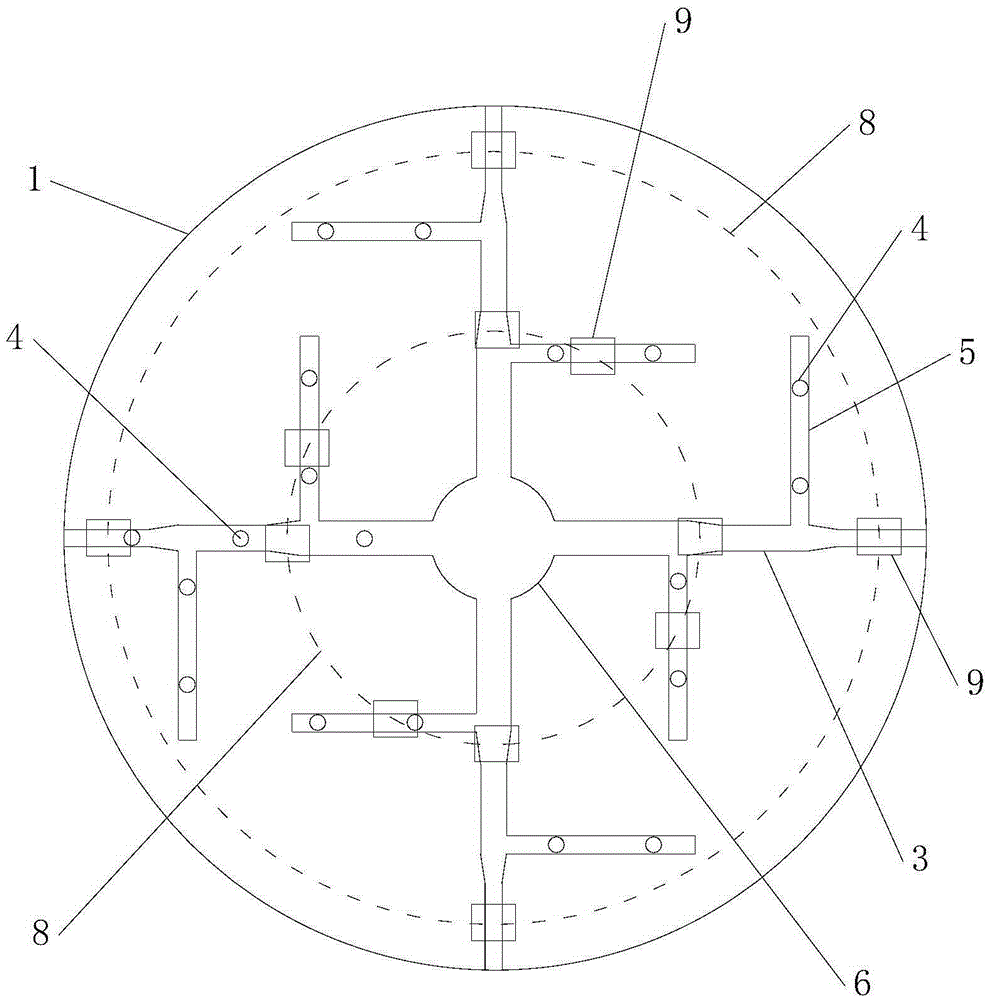

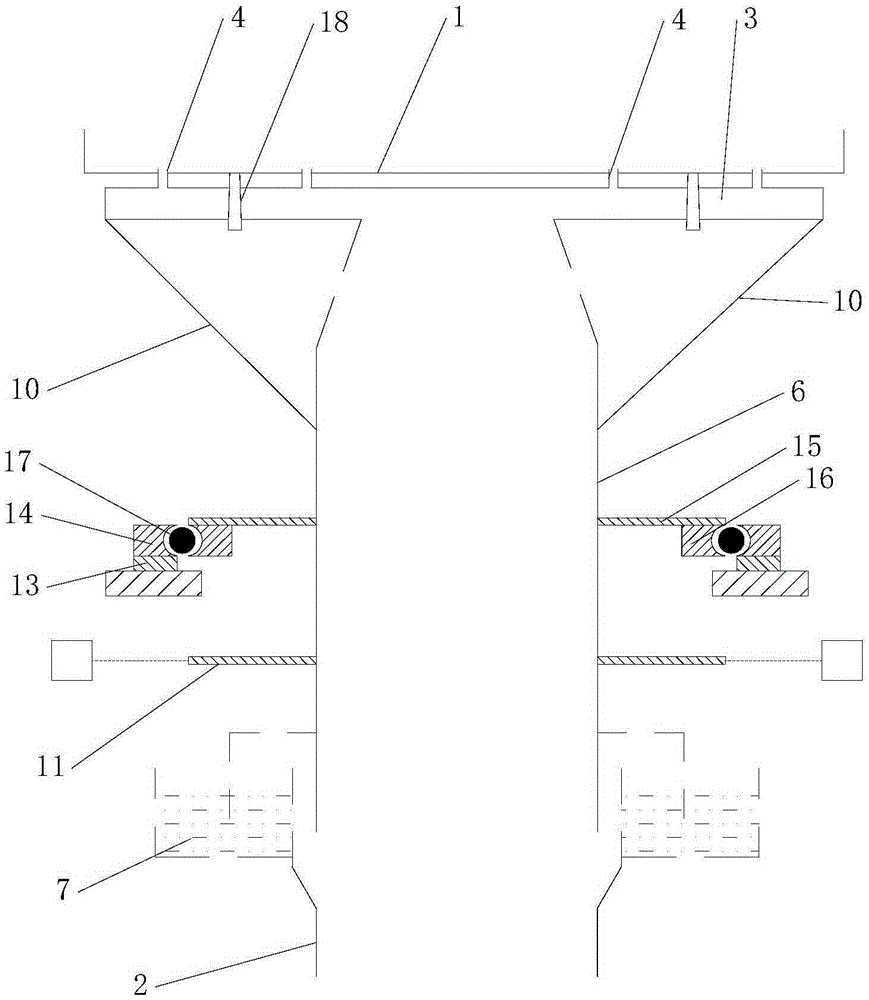

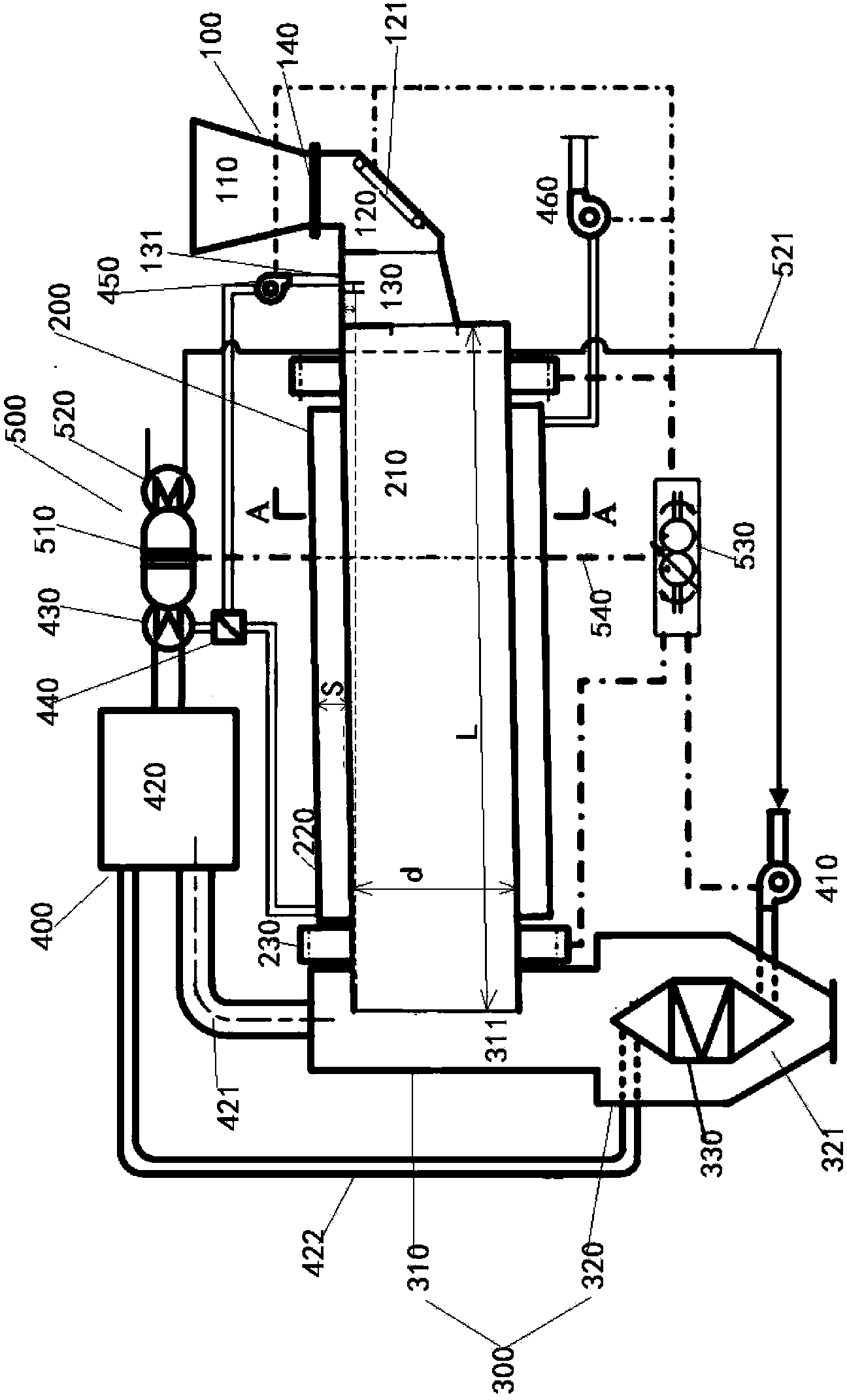

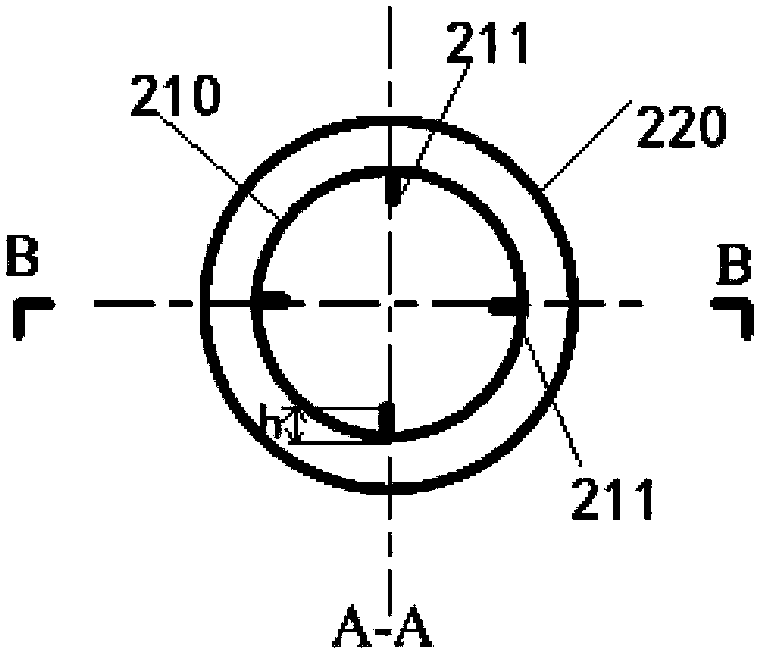

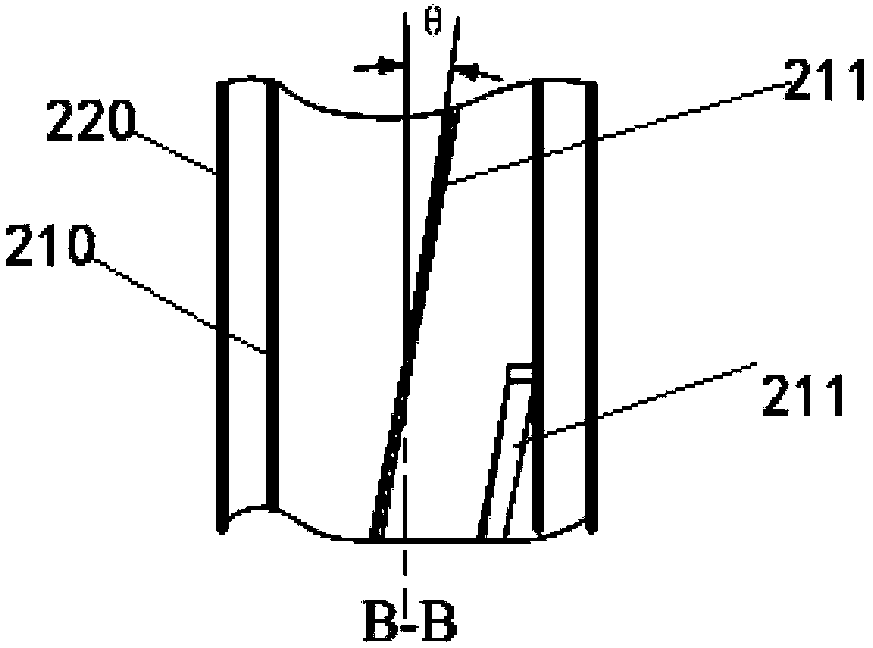

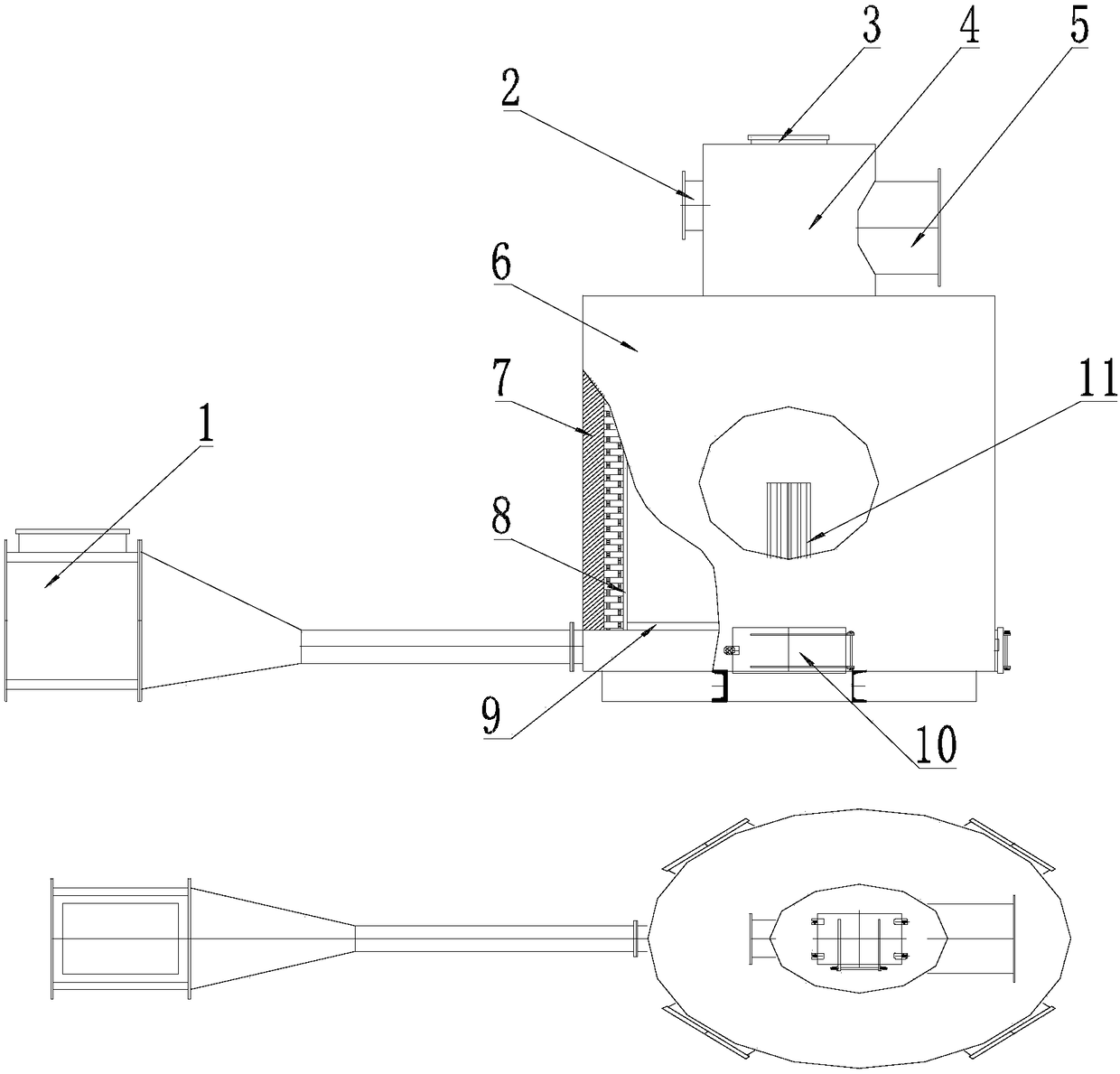

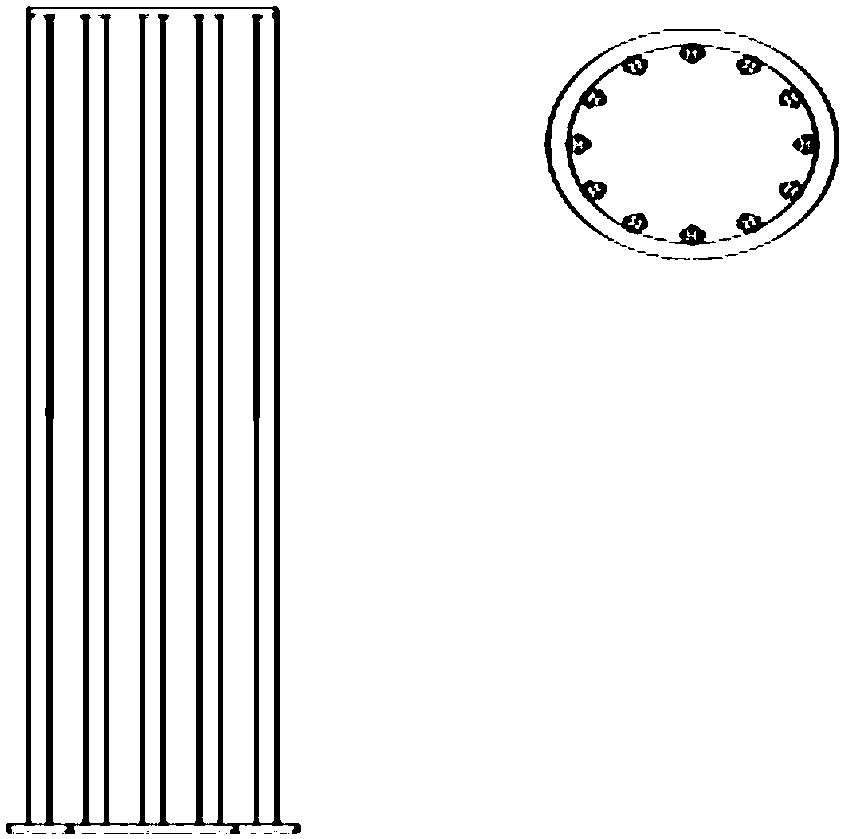

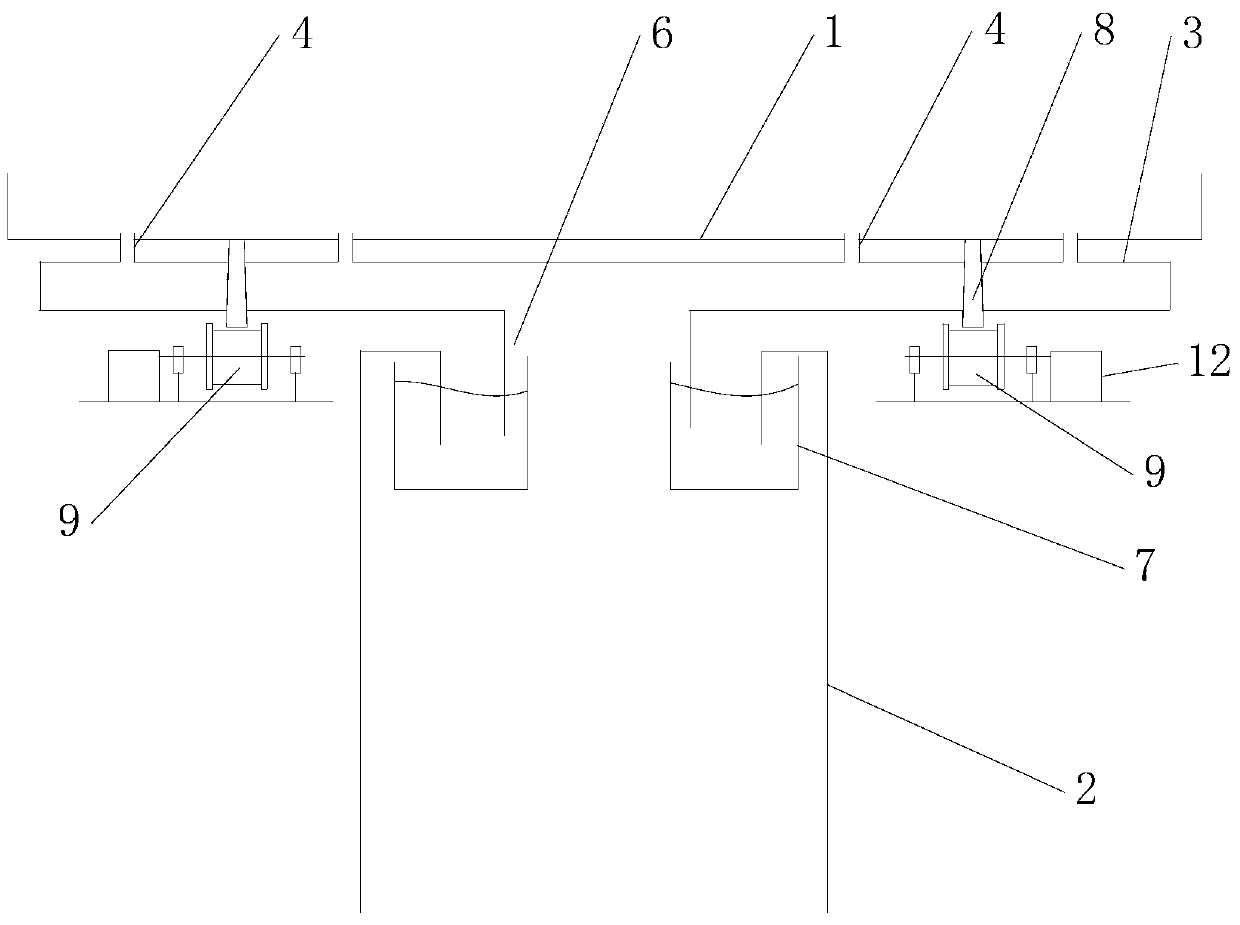

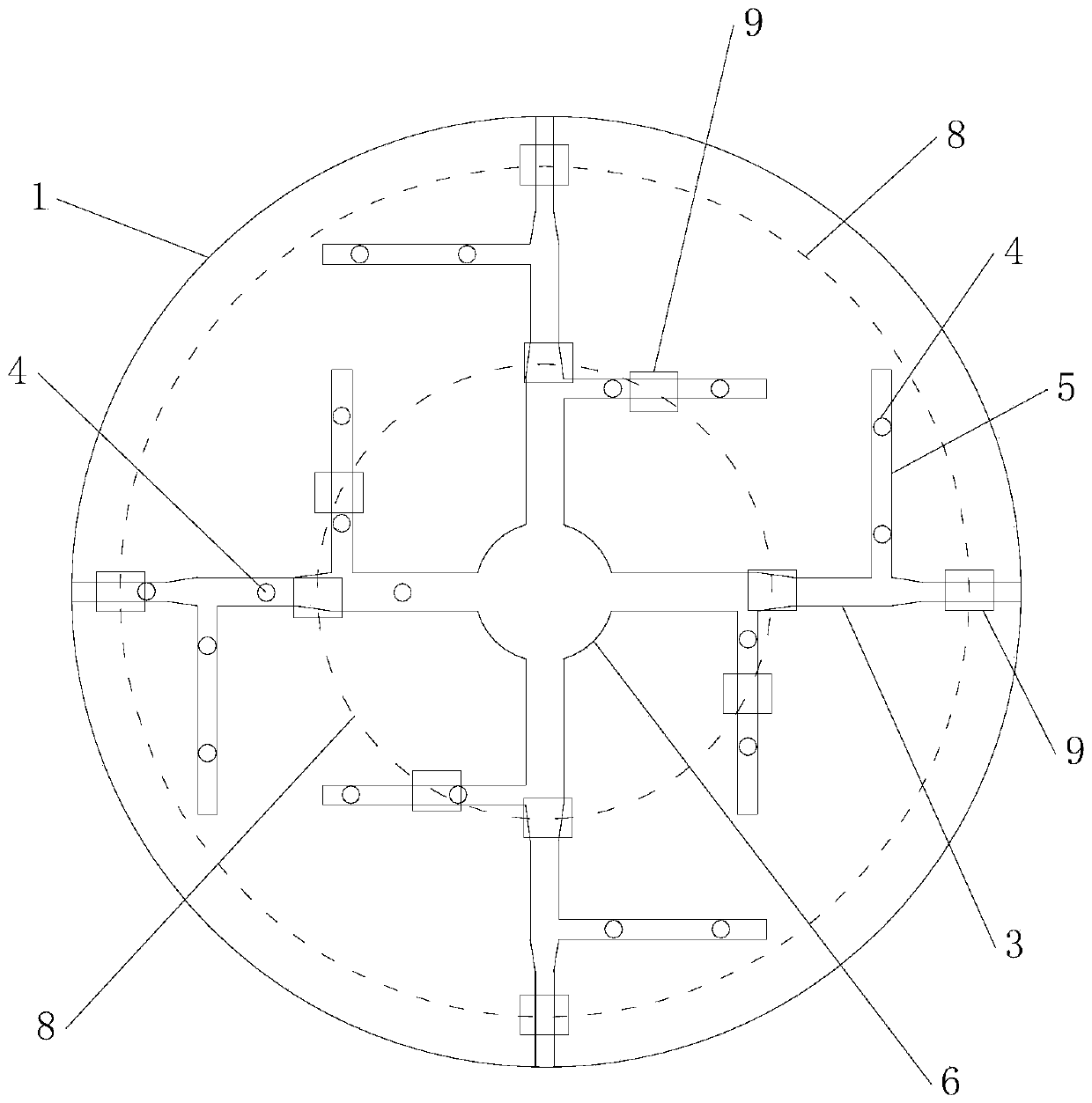

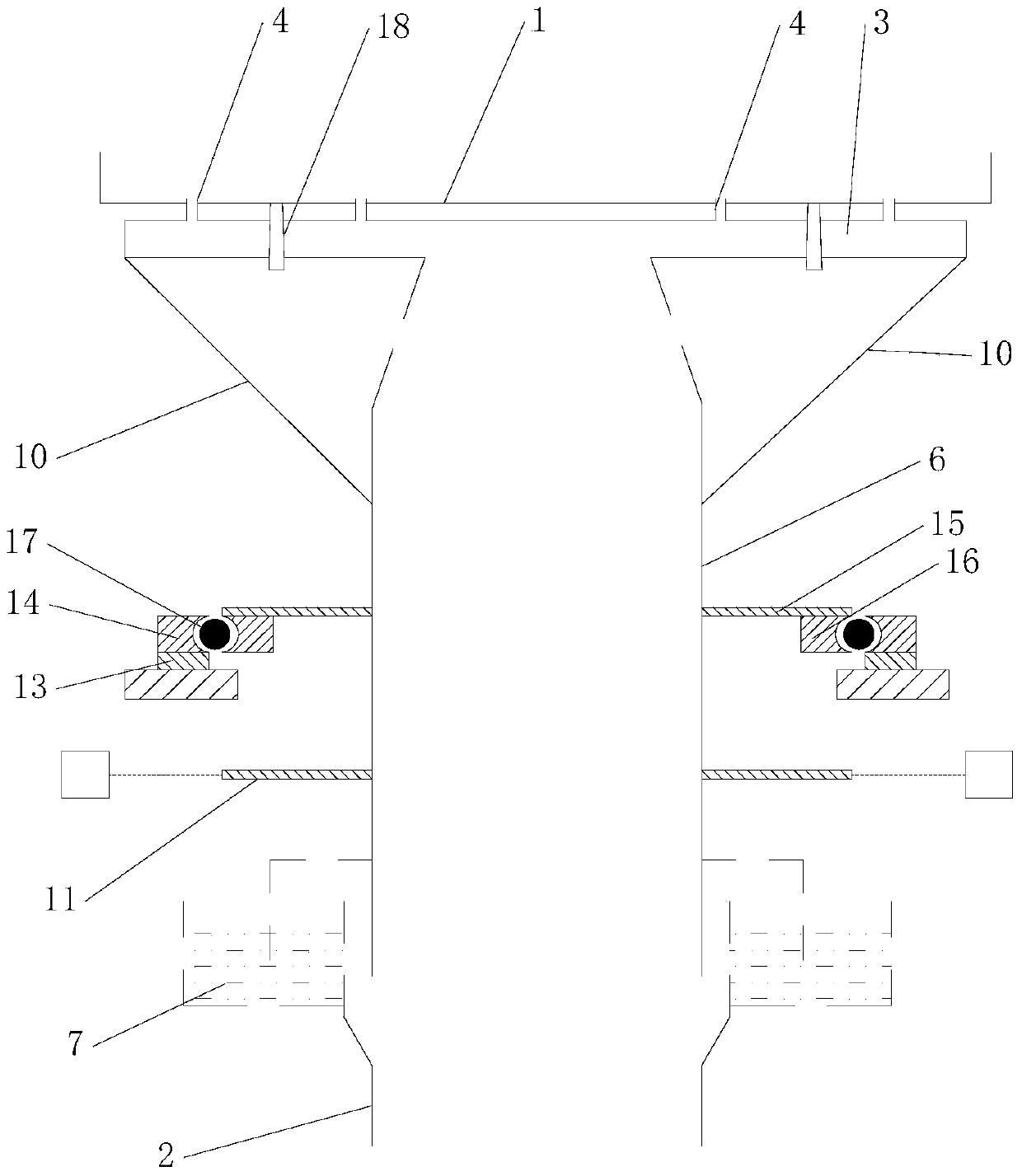

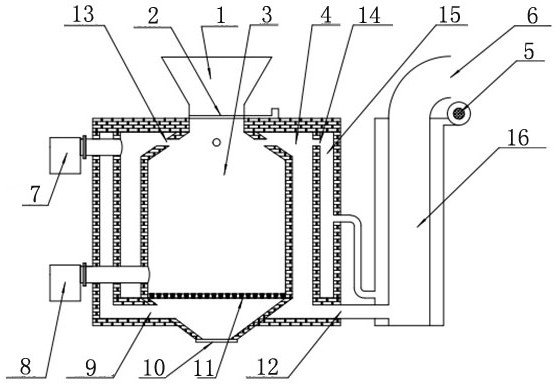

Disc type reactor

ActiveCN106554785AIncrease drying temperatureRaise the pyrolysis temperatureDirect heating destructive distillationDrying gas arrangementsProcess engineeringProduct gas

The invention discloses a disc type reactor which comprises a drying or pyrolyzing tray (1), a rotation driving device used for driving the tray (1) to rotate and a gas distributing device used for conveying high-temperature gas into the tray (1). The gas distributing device comprises a gas distributing unit which is arranged under the tray (1) and can rotate along with the tray (1) and a hot blast main pipe (2) used for supplying gas to the gas distributing unit. The gas distributing unit communicates with the upper space of the tray (1), and the rotation driving device is located outside the gas distributing device. By adoption of the disc type reactor, higher drying or pyrolyzing temperatures can be obtained, and therefore the disc type reactor can meet pyrolyzing and upgrading requirements of coal of more types, central gas supply is adopted, and the height of a bed can be effectively decreased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

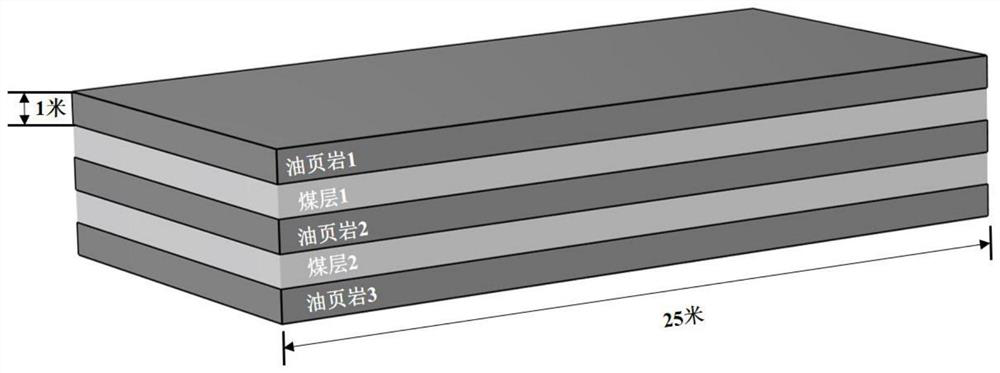

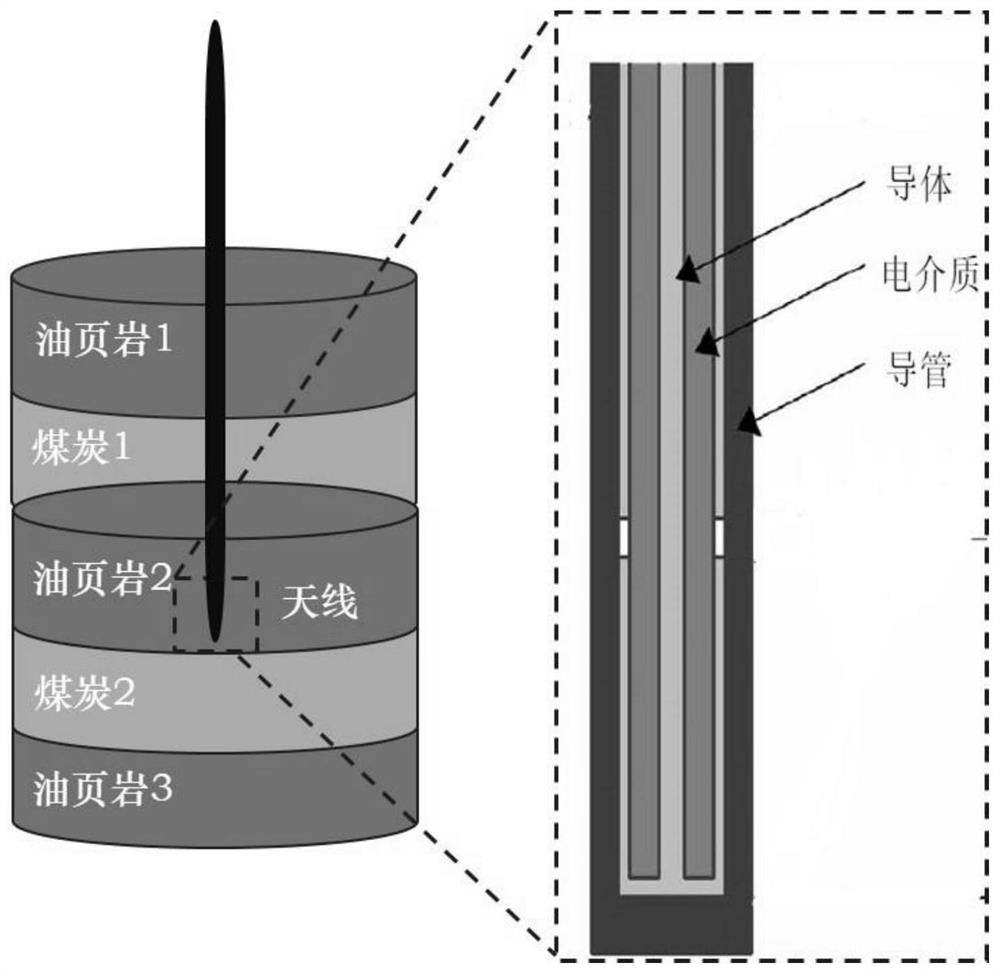

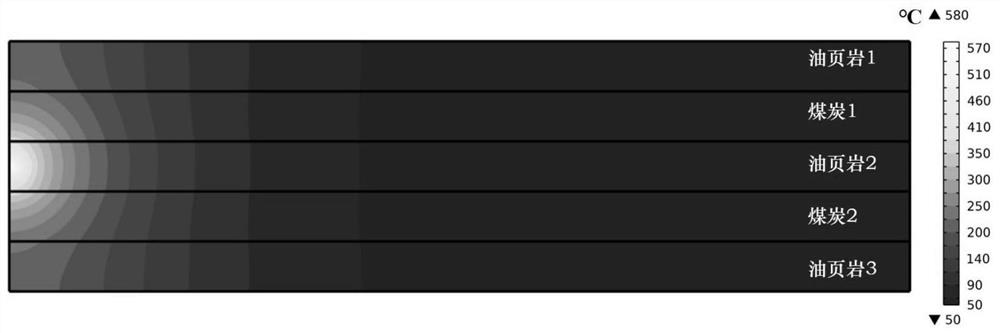

Oil shale and coal interbed collaborative in-situ mining method

ActiveCN113236212AImprove microwave pyrolysis efficiencyImprove qualityConstructionsFluid removalHeating oilProcess engineering

The invention discloses an oil shale and coal interbed collaborative in-situ mining method. The method is characterized in that based on associated geological characteristics of oil shale and coal interbed, the oil shale and coal are subjected to in-situ co-heating by adopting a microwave heating method, so that the oil shale and the coal are subjected to co-pyrolysis and are converted into liquid and gaseous organic matters, and then the liquid and gaseous organic matters flow into a shaft through pores and crack channels, and produced by a production well. According to the oil shale and coal interbed collaborative in-situ mining method, the microwave heating in-situ pyrolysis method is adopted, mechanical physical mining is converted into electromagnetic chemical pyrolysis mining, and physical coal mining is changed into chemical gas mining, so that unnecessary heat energy consumption is reduced, the pyrolysis efficiency of the oil shale and the coal is improved, the quality grade of pyrolysis products is increased, and pollution to the environment is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

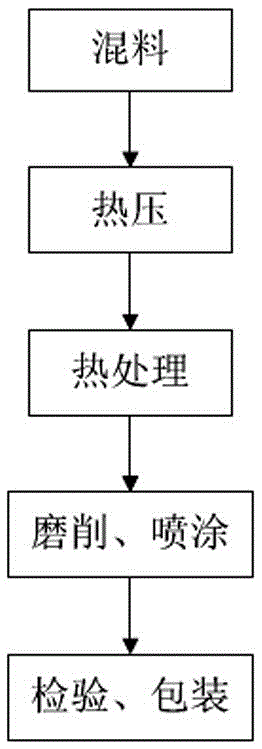

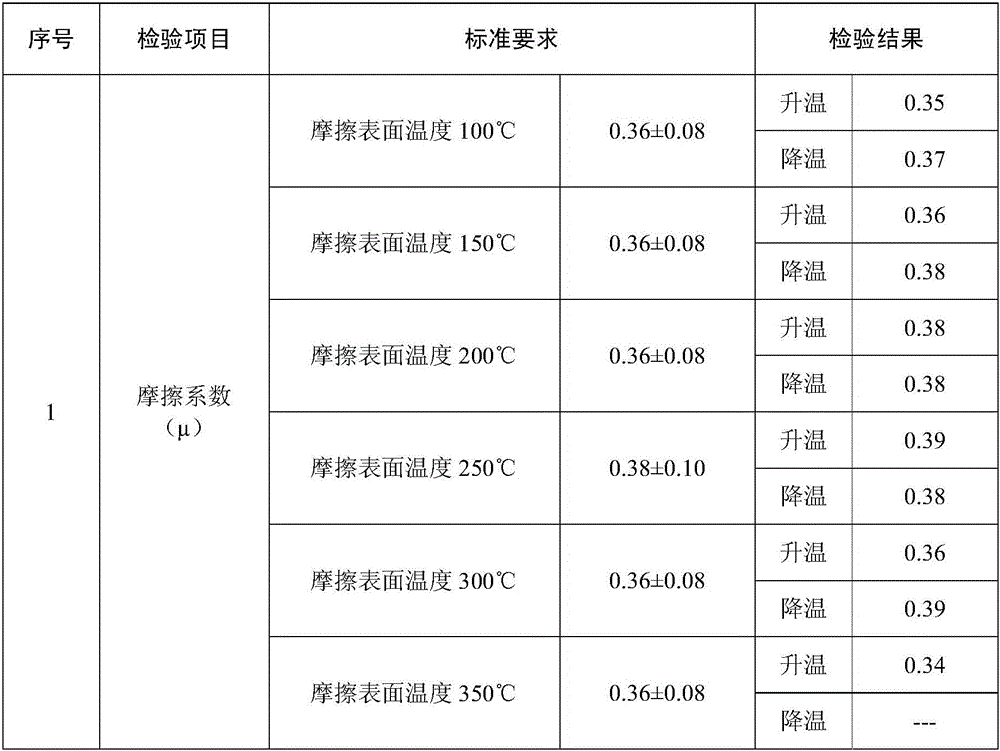

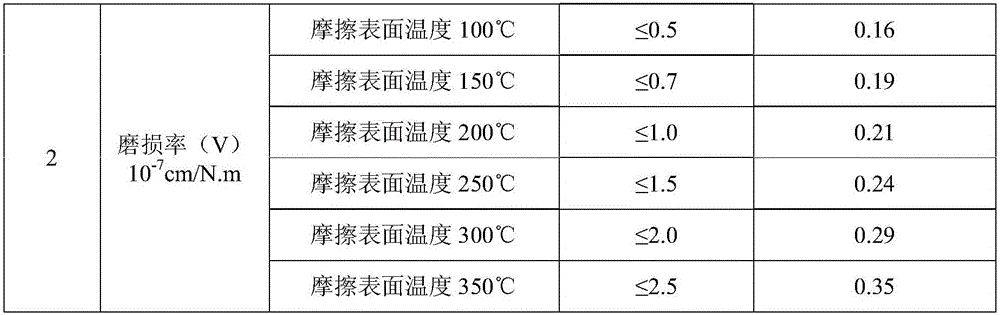

Automobile friction lining with flame-retardant function and production method of automobile friction lining

InactiveCN106438792ARaise the pyrolysis temperatureEliminate the risk of brake failureOther chemical processesFriction liningPotassium feldsparPowder metallurgy

The invention provides an automobile friction lining with a flame-retardant function and a production method of the automobile friction lining in order to solve the problem such as braking failure resulted from heating decomposition easily existing in a friction material of a disc brake in the prior art. The friction material comprises the components in percentage by weight: 10-16 parts of phenol-formaldehyde resin, 28-35 parts of steel wool, 3-8 parts of cokes, 3-10 parts of mineral fibers, 4-8 parts of nanoscale magnesium oxide, 15-20 parts of barium sulfate, 10-18 parts of graphite, 2-6 parts of potassium feldspar and 0.5-2 parts of zinc borate. The automobile friction lining with the flame-retardant function and the production method of the automobile friction lining have the beneficial effects of raising the thermal cracking temperature of a brake pad, eliminating the hidden danger of braking failure caused by high braking temperature and achieving the technical effect of replacing a powder metallurgy brake pad on the premise that the braking performance of the brake pad completely meets relevant standard requirements.

Owner:CHONGQING HONGYU FRICTION PROD

Composition of thermosetting resin and copper foil laminated plate

ActiveCN101942178BSufficient flame resistanceRaise the pyrolysis temperatureMetal layered productsEpoxyLow dissipation

The invention relates to composition of a thermosetting resin. The thermosetting resin comprises dicyclopentadiene epoxy resin, benzoxazine, maleimide, styrene / maleic anhydride copolymer, filler, flame retardant and imidazole accelerant. The thermosetting resin is used for a high-speed transmission copper foil laminated plate, has the dielectric properties of low dielectric constant and low dissipation factor, and can be used for a high-speed signal transmission copper foil laminated plate. In addition, the thermosetting resin does not contain halogens, thereby having the advantage of environmental protection.

Owner:ELITE MATERIAL

Biomass pyrolysis system and method through self-sufficient energy

ActiveCN103146403BImprove heat utilizationImprove thermal efficiencyDirect heating destructive distillationBiofuelsFlue gasMechanical energy

The invention discloses a biomass pyrolysis system and method through self-sufficient energy. The biomass pyrolysis system comprises a feeding device, a pyrolysis device, a separating and cooling device, an air flue gas component and a generating power component, wherein the pyrolysis device is connected with the feeding device so as to perform pyrolysis on the biomass raw materials; the separating and cooling device is connected with the pyrolysis device so as to receive and separate coke and pyrolysis gas output by the pyrolysis device; the air flue gas component is connected with the separating and cooling device so as to combust the pyrolysis gas and the preheated air and respectively feed the gas back to the feeding device and the pyrolysis device; and the generating power component is connected with the air flue gas component so as to convert the heat of the pyrolysis gas and the preheated air into mechanical energy and supplement the power source of the pyrolysis device and the separating and cooling device. According to the biomass pyrolysis system, the energy of the biomass pyrolysis gas product is subjected to gradient utilization, and the system has the advantages of self-sufficient energy, low cost and the like.

Owner:TSINGHUA UNIV

Mildew-proof traditional Chinese medicine beverage packaging bag and processing method thereof

ActiveCN112409643AImprove mechanical propertiesReduce clumpingMicroballoon preparationHollow articlesLinear low-density polyethyleneCellulose

The invention discloses a mildew-proof traditional Chinese medicine beverage packaging bag which comprises the following raw materials in parts by weight: 100-200 parts of polymer matrix, 5-10 parts of maleic anhydride grafted polyethylene and 10-12 parts of mildewproof agent. The processing method of the mildew-proof traditional Chinese medicine beverage packaging bag comprises the following steps: step 1, uniformly stirring the polymer matrix and the maleic anhydride grafted polyethylene, conducting blending through a double-screw extruder, carrying out melt extrusion, conducting cutting toform particles by using a granulator; and 2, uniformly mixing the particles prepared in the step 1 with a mildew preventive, connecting a single-screw extruder with a casting machine, carrying out melt extrusion to prepare a packaging bag film, and carrying out slitting and bag making to obtain the mildew-resistant traditional Chinese medicine beverage packaging bag. On the premise that the mildew-proof effect of the packaging bag is guaranteed, a coupling agent reacts with the microfibrillated cellulose and the linear low-density polyethylene in a bidirectional mode, combination of the microfibrillated cellulose and the linear low-density polyethylene is achieved, and the mechanical property of the packaging bag is improved.

Owner:丽的包装(广东)有限公司

High-temperature adhesive for forming jet coal and quick lime mixed pellets and preparation method thereof

InactiveCN106753653AHigh strengthMeet the requirements for smelting into calcium carbide furnaceSolid fuelsCalcium carbideAdhesiveHigh intensity

The invention discloses a high-temperature adhesive for forming jet coal and quick lime mixed pellets and a preparation method thereof. The high-temperature adhesive is prepared from the following steps: adding a CS2 / NMP mixed solvent into crushed adhesive coal particles for extraction and performing centrifugal separation to obtain an extraction solution; adding rubber powder, a crosslinking agent, an accelerant and an activating agent into extract liquor to obtain a mixture; performing a reaction on the mixture; and distilling a reaction product, and washing and drying the residues to obtain the high-temperature adhesive. The invention further provides a method of improving the high-temperature strength of the jet coal and quick lime mixed pellets by using the high-temperature adhesive. The method comprises the following steps: uniformly mixing the jet coal, the quick lime and the high-temperature adhesive, and performing press moulding to obtain the pellets; and performing pyrolysis on the pellets to obtain high-strength pyrolyzed pellets. The high-temperature adhesive disclosed by the invention is wide in source of raw materials and low in cost, can effectively improve the strength of the jet coal and the quick lime mixed pellets without cohesiveness after pyrolysis, and meets the demand of directly feeding the pellets into a calcium carbide furnace to be smelted.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Thermosetting resin composition and application

The invention discloses a thermosetting resin composition, which comprises the following components: bifunctional or multifunctional epoxy resin, styrene-maleic anhydride copolymer SMA as a curing agent with styrene / maleic anhydride molar ratio of 5-12:1, low-bromine or high-bromine BPA type epoxy resin or tetrabromo bisphenol A as a fire retardant, an accelerator and a solvent. The resin composition after curing has quite low dielectric property, higher heat reliability and better toughness, has quite low dielectric constant and dielectric loss coefficient, high Td, better toughness and excellent PCB processability with a copper-clad plate made of glass fiber cloth and other reinforcing materials, is suitable for manufacturing a copper-clad plate and a semi-cured plate for PCB, and can also be used in common application of the epoxy resin, such as molding resin, composite materials for buildings, automobiles and aviation, and the like.

Owner:ITEQ DONGGUAN

Method for preparing levoglucosenone

InactiveCN112645962AFacilitate Selective TransformationImplement resourcesSugar derivativesOrganic chemistry methodsEnvironmental engineeringCo pyrolysis

The invention discloses a method for preparing levoglucosenone. The method comprises the following steps: grinding and mixing waste strongly acidic macroporous resin Amberlyst-15 and cellulose powder according to a mass ratio of (0.1-1): 1, and carrying out co-pyrolysis in an oxygen-free environment at 250-450 DEG C to prepare the levoglucosenone. According to the method, the waste strongly acidic macroporous resin Amberlyst-15 and the cellulose are subjected to co-pyrolysis treatment, so that the selective conversion of the cellulose to levoglucosenone can be promoted, and the green resource utilization and treatment of the waste resin high polymer can be realized. The method is simple and easy to implement, and can be further popularized and applied to pyrolysis conversion of other wood fiber biomass resources and green resource reutilization and co-treatment of waste resin.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

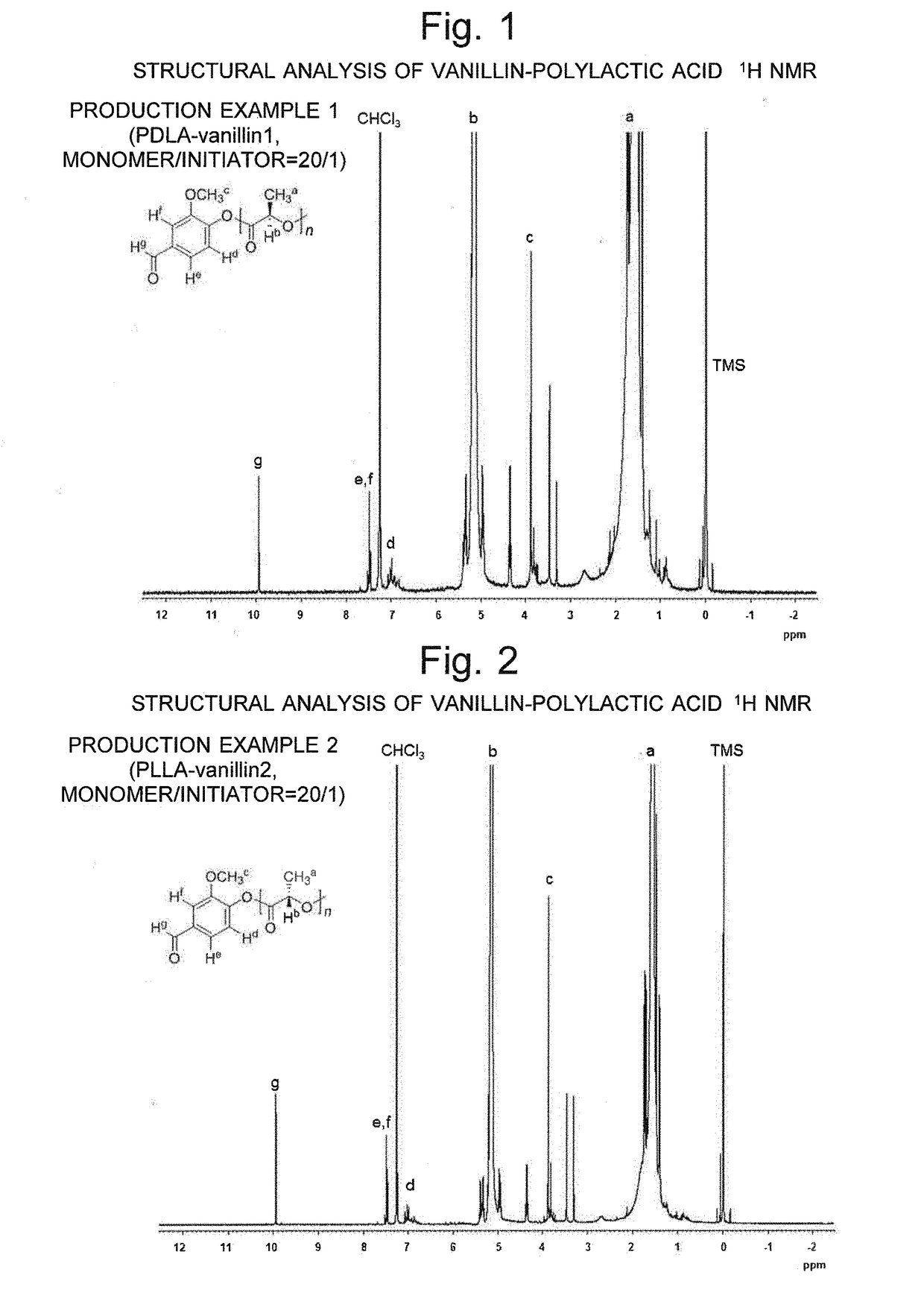

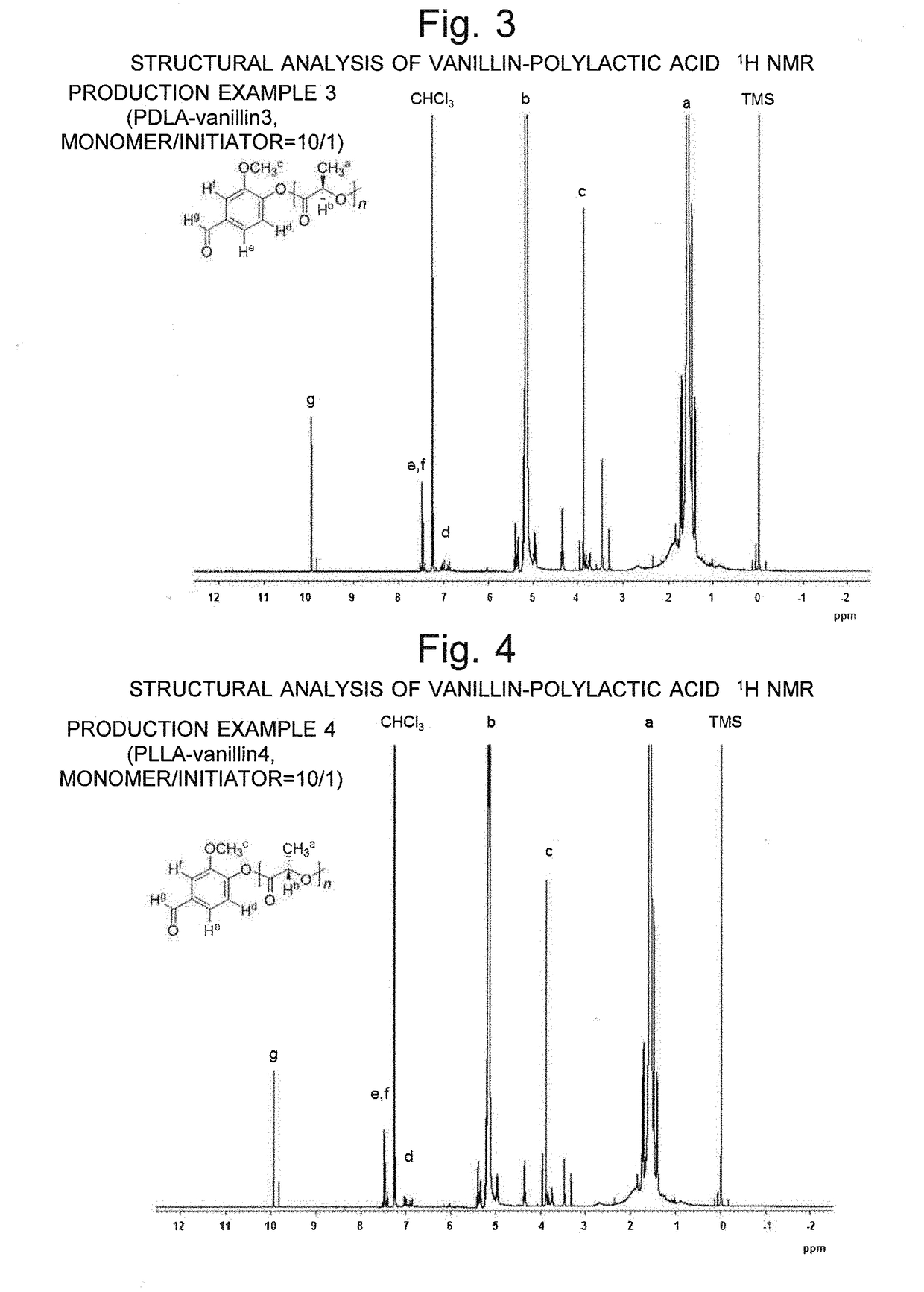

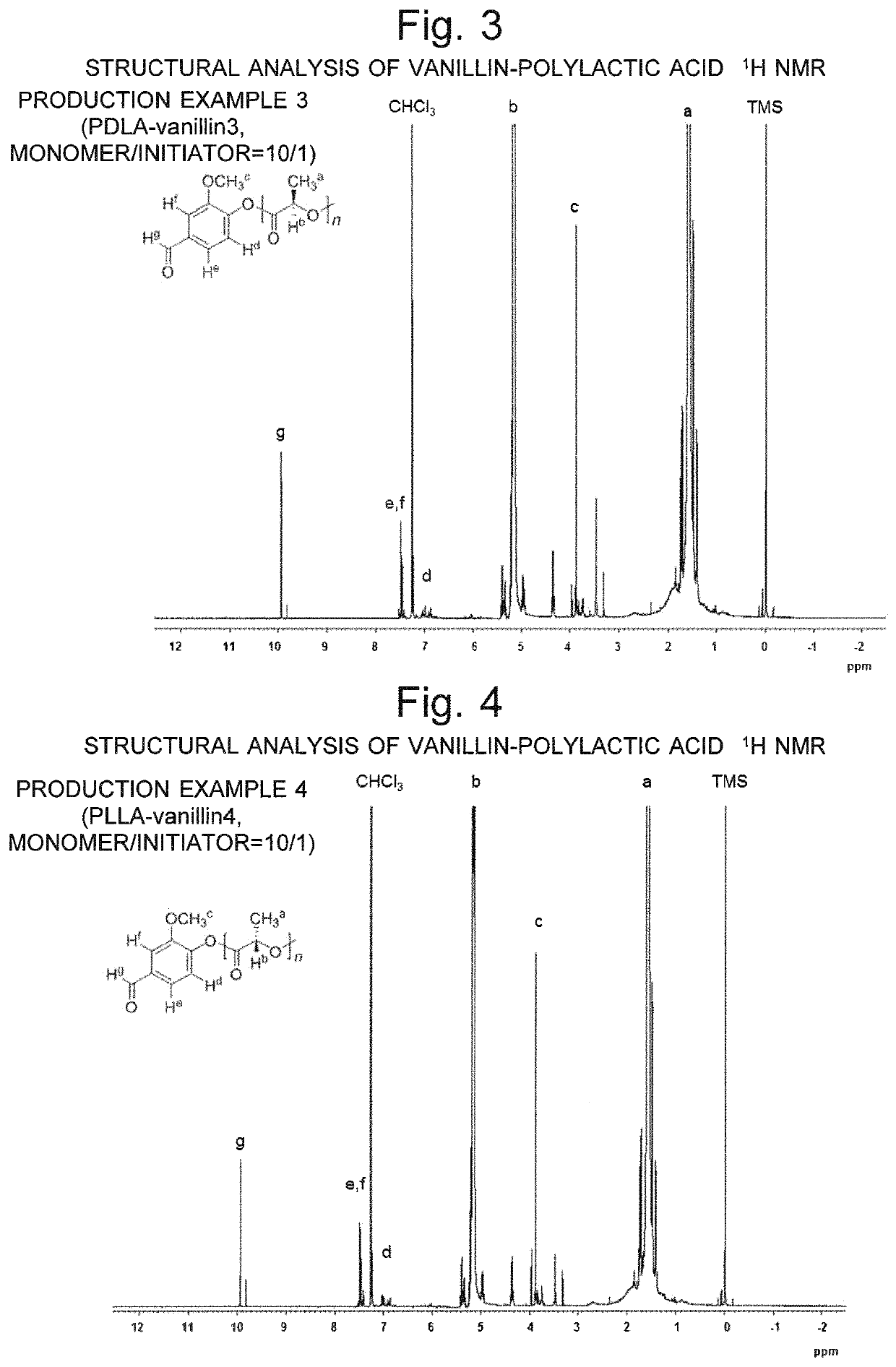

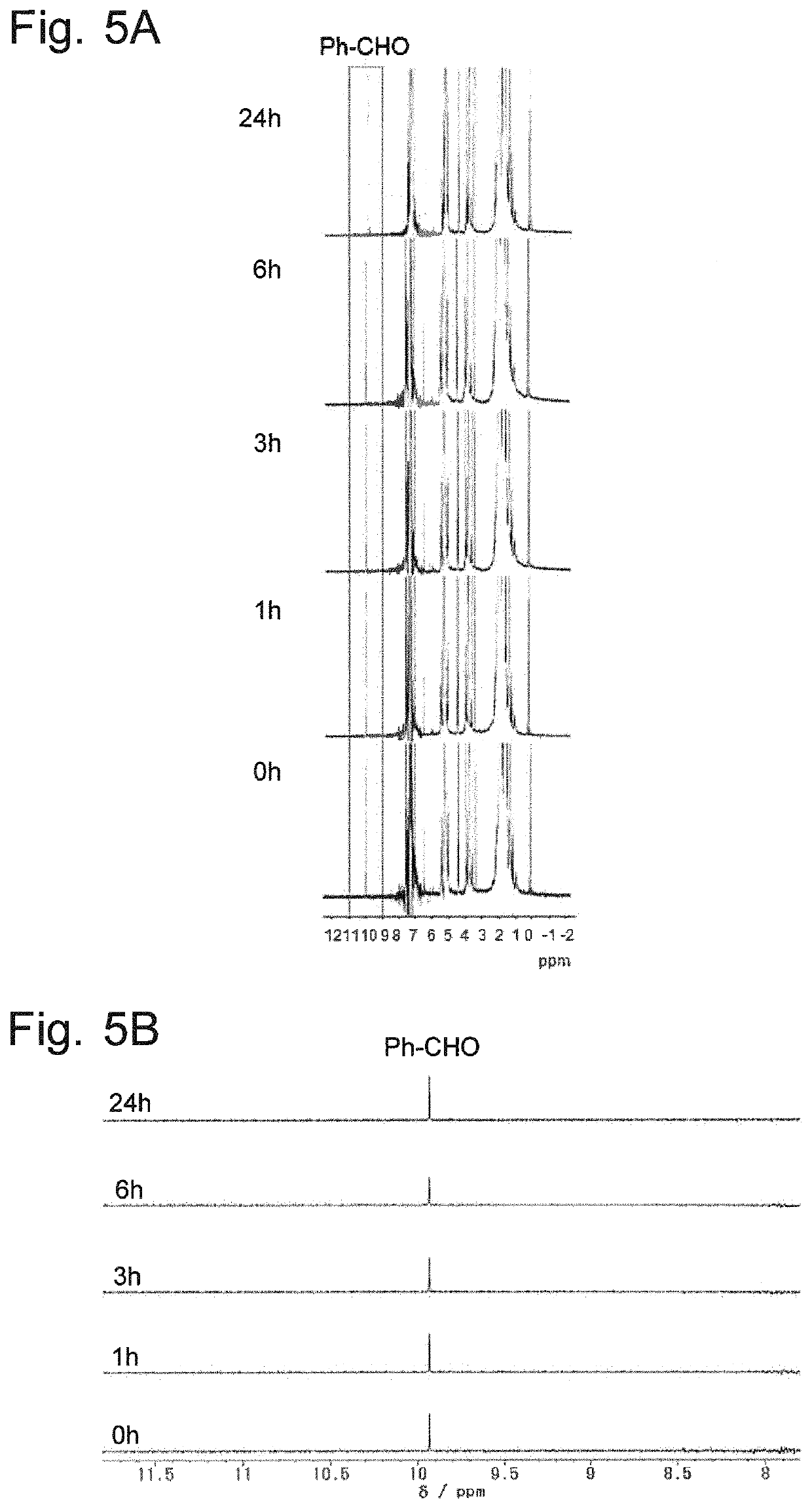

Polylactide derivative, method for producing same, and polylactide stereocomplex

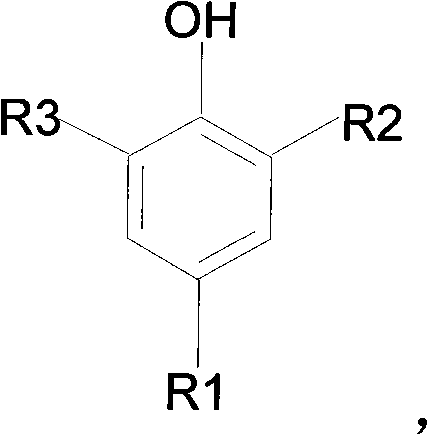

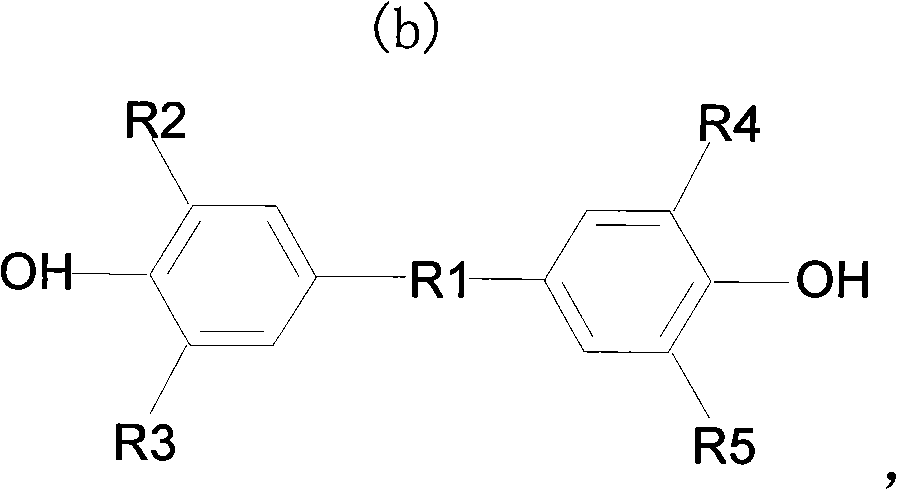

A polylactide derivative according to the present invention is expressed by the following general formula (1) or general formula (2):In general formula (1), one of X1-X5 is an aldehyde group, one of the other four is an alkoxy group, and the other three are hydrogen atoms.In general formula (2), one of R1-R3 is selected from a chlorine atom, fluorine atom, aldehyde group, alkoxy group, alkyl group and ester, while the other two are selected from the chlorine atom, fluorine atom, aldehyde group, alkoxy group, alkyl group, ester, and hydrogen atom.

Owner:NARA INSTITUTE OF SCIENCE AND TECHNOLOGY

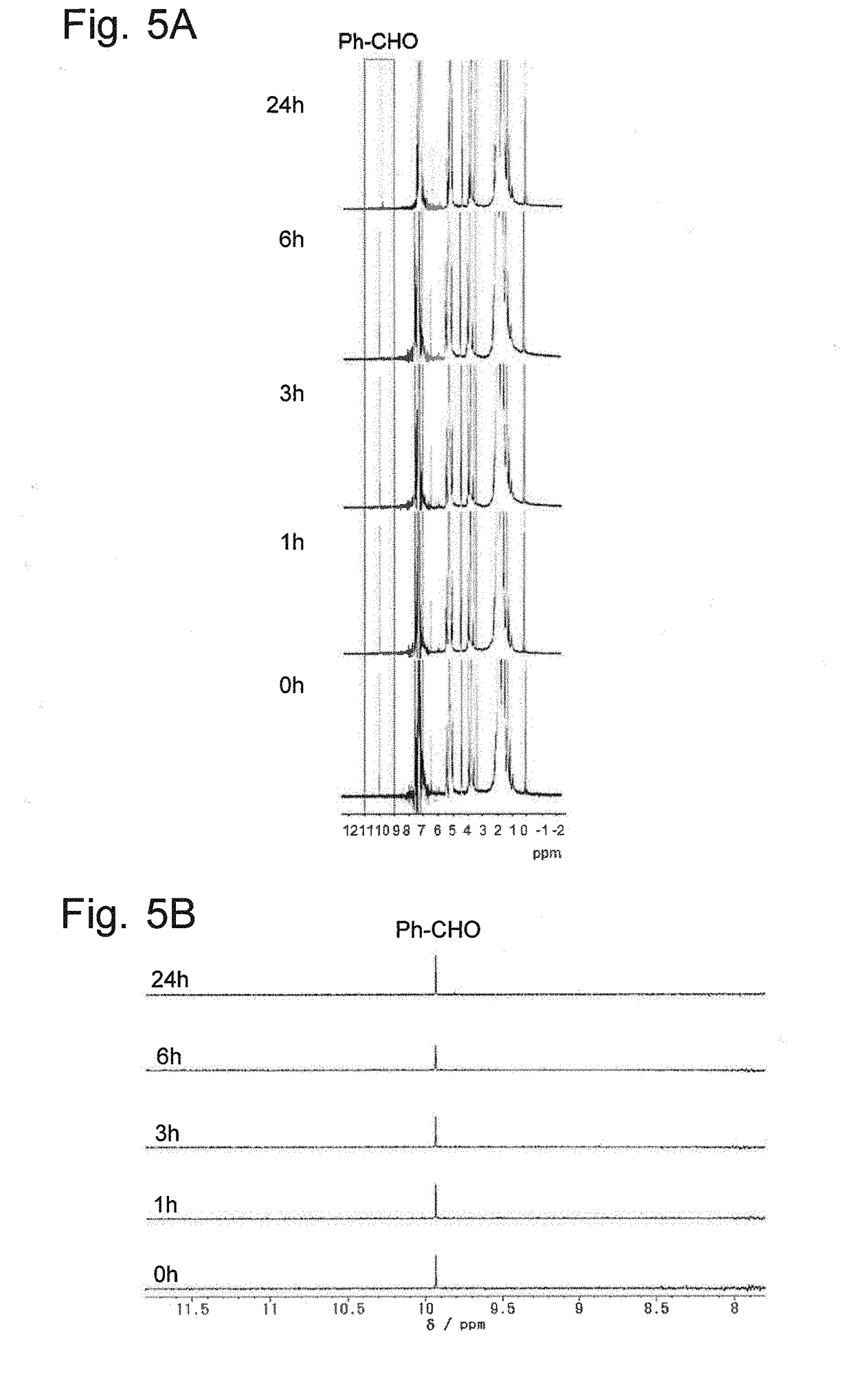

A kind of rare earth-based luminescent material containing multi-acid building blocks and its preparation method and application

The invention discloses a rare earth-based luminescent material containing polyacid building units, a preparation method and application thereof, and belongs to the technical field of preparation and application of organic-inorganic chemical hybrid materials. The specific chemical formula of the rare earth-based luminescent material of the present invention is: [Tb 6 (C 16 h 6 o 9 ) 4 (HCOO) 2 (DMF) 4 (H 2 O) 4 ]·2DMF·9H 2 O, the molecular formula is: C 84 h 94 N 6 o 59 Tb 6 , where C 16 h 6 o 9 is 5‑(3’,4’‑dicarboxyphenoxy)isophthalic acid, and DMF is N,N‑dimethylformamide. The present invention uses DMF solvothermal method to prepare the rare earth-based luminescent material containing multi-acid building units. It is a newly synthesized product. It shows bright grass-green fluorescence under the irradiation of ultraviolet lamps, with uniform and pure color, high brightness, and is located in visible light At the same time, the synthesis process of the present invention is simple, the crystallization degree of the material is high, the shape is regular, the purity and yield of the target product are high, and the present invention can be widely used in various energy-saving lamps, fluorescent imaging, fluorescent sensors, new light sources, etc. Fields and promotion of plant growth, ultraviolet disinfection, medical care and other medical and health fields.

Owner:HUAINAN NORMAL UNIV

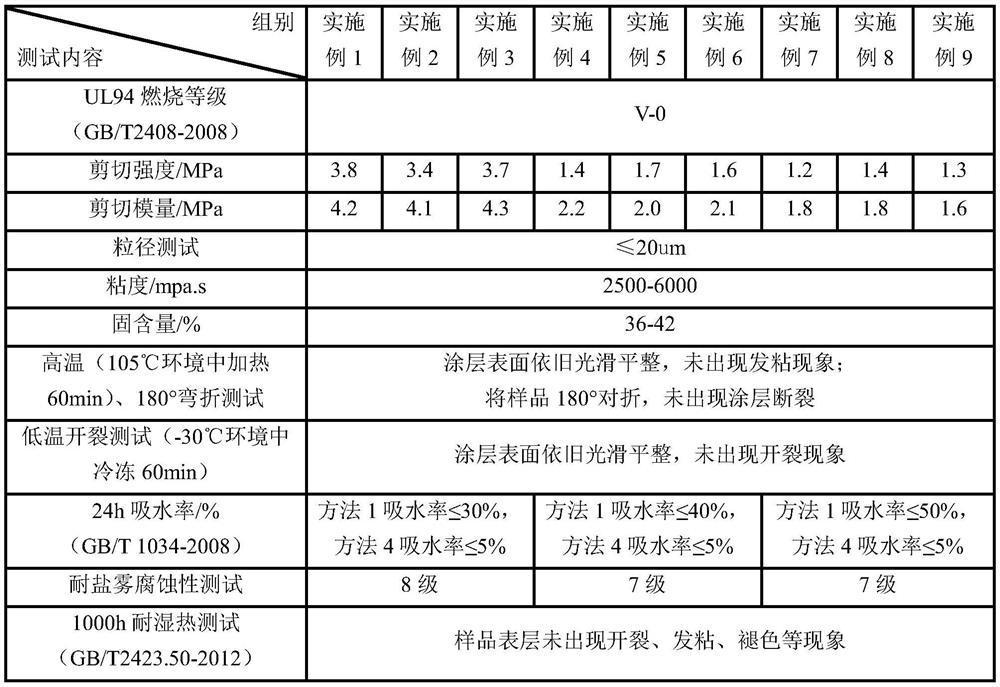

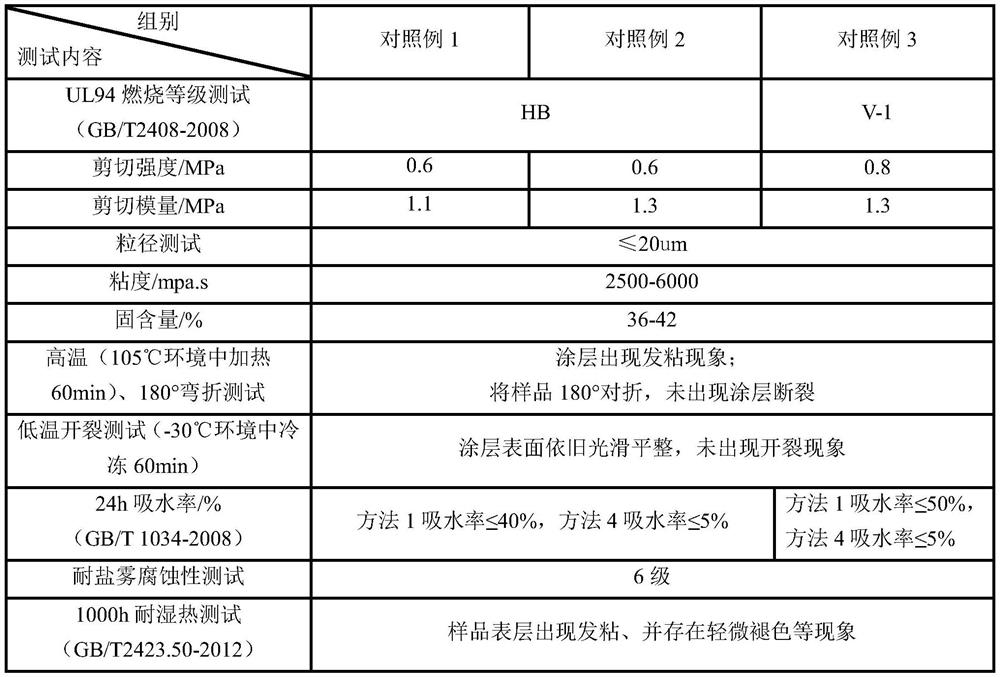

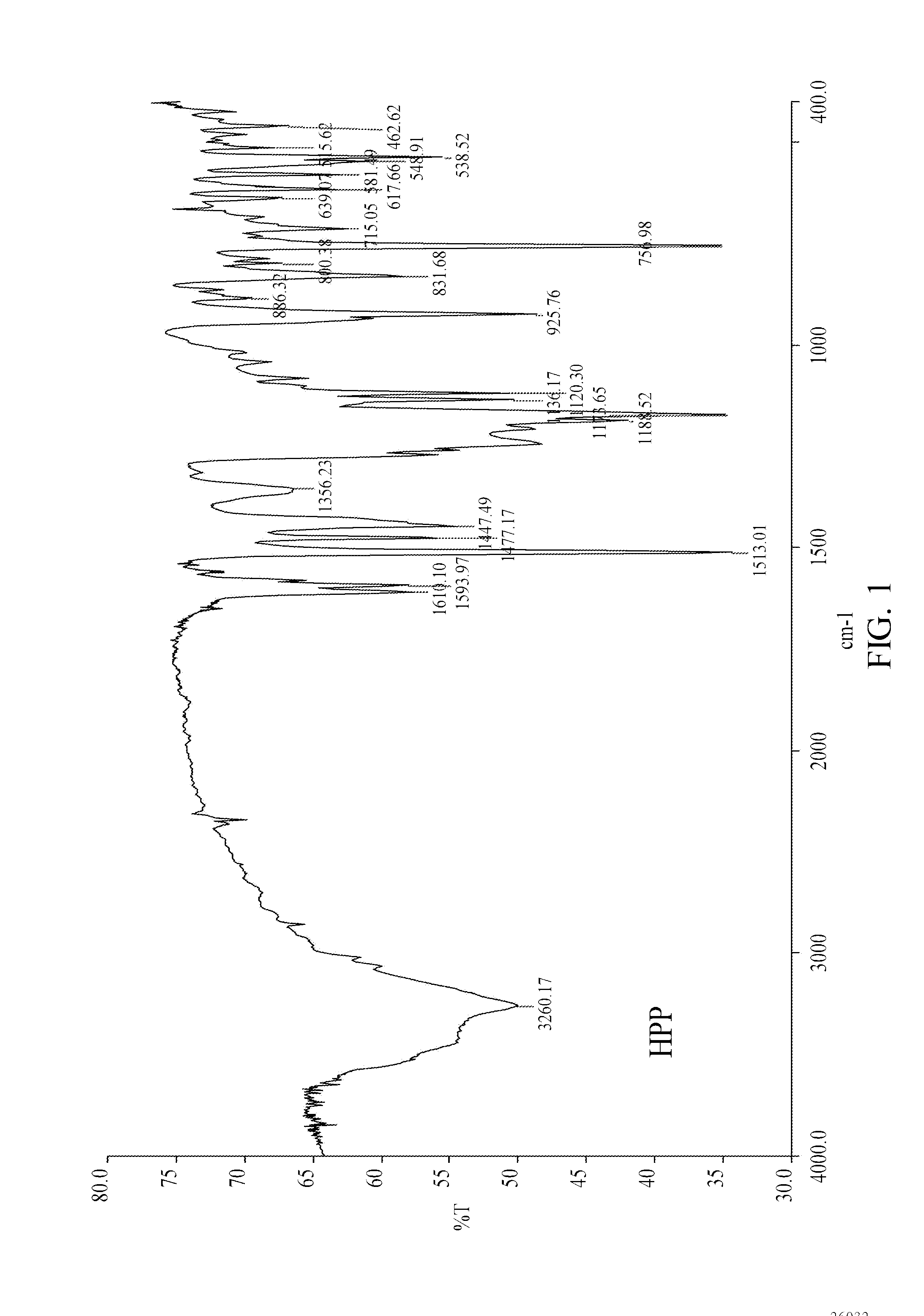

Packaging flame-retardant coating for aerogel and production process of packaging flame-retardant coating

PendingCN114806325AReduce generationImprove flame retardant performanceFireproof paintsPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a packaging flame-retardant coating for aerogel and a production process thereof, and the packaging flame-retardant coating comprises the following raw materials in parts by mass: 20-100 parts of a resin matrix, 40-100 parts of a compound flame retardant, 60-100 parts of a water solvent, 2-10 parts of carbon black color paste, 2-20 parts of a chemical additive, 1-8 parts of a thickening agent and 1-25 parts of a curing agent, the resin matrix is any one or two or more of epoxy resin, polyurethane resin, acrylic resin and silicone rubber; the compound flame retardant is any one or two or more of a metal hydroxide flame retardant, a phosphorus flame retardant and a nitrogen flame retardant. The flame-retardant packaging coating provided by the invention has the advantages of wide material sources, no need of large precise instruments, simple production process and wide application range, and the obtained flame-retardant coating has excellent flame-retardant and high-temperature-resistant characteristics, excellent mechanical properties, chemical resistance and high adhesive force.

Owner:河南普力特克新材料有限公司 +1

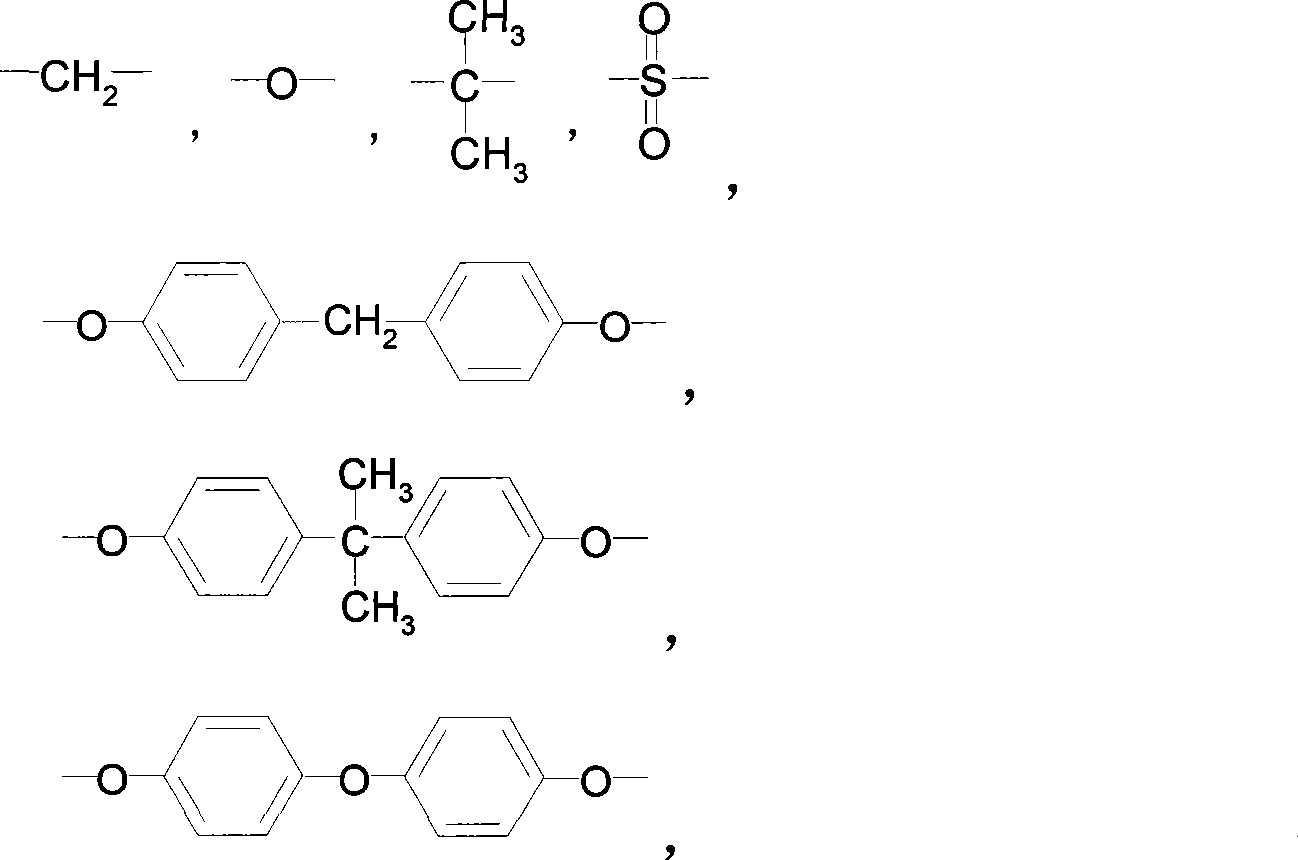

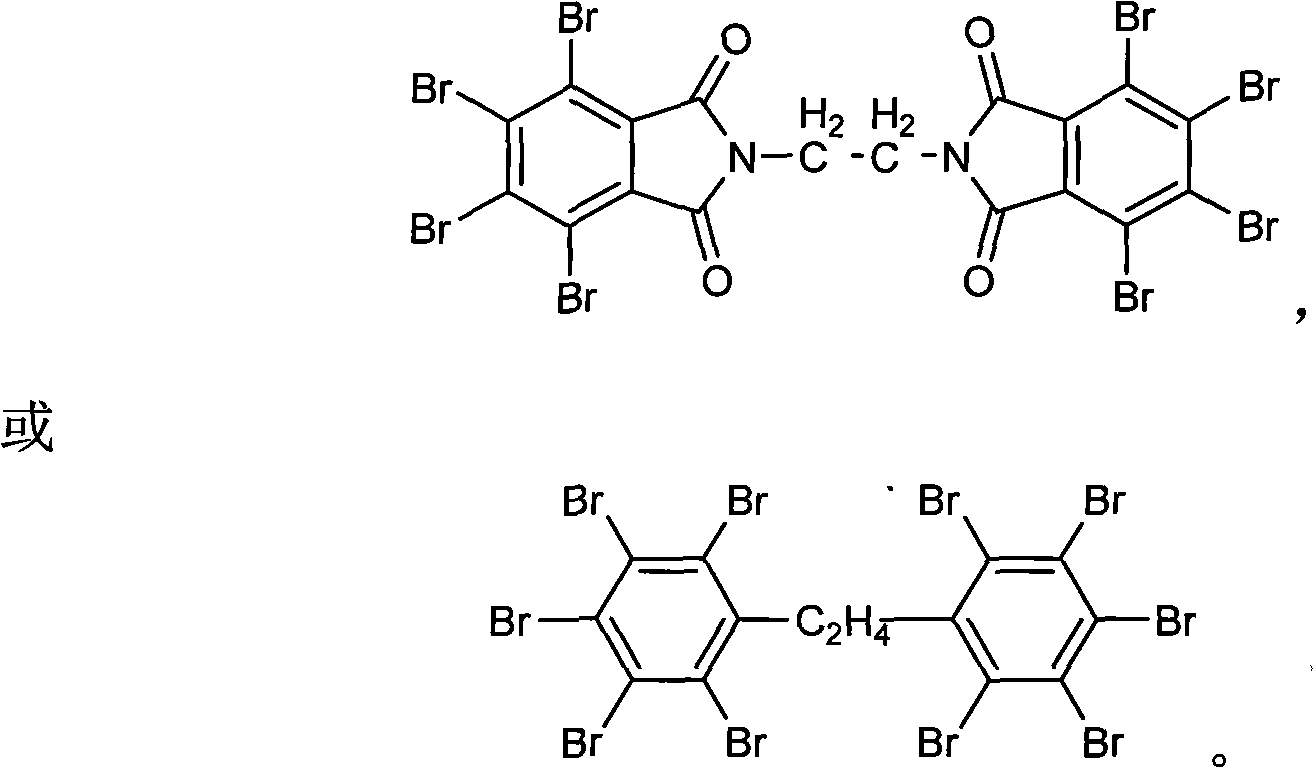

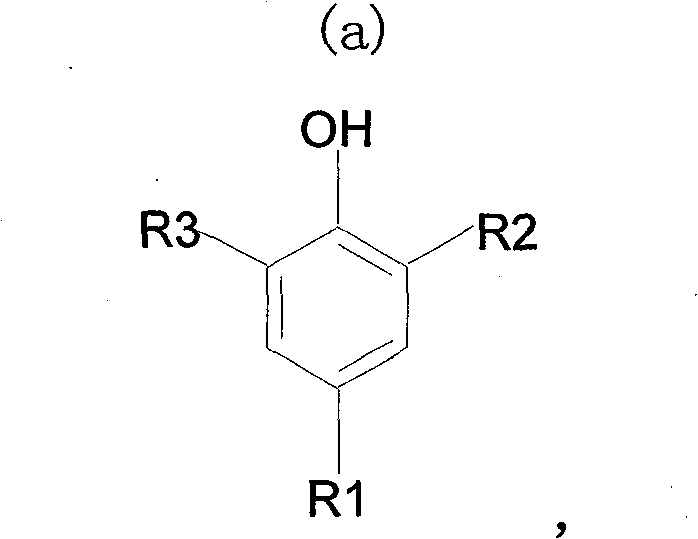

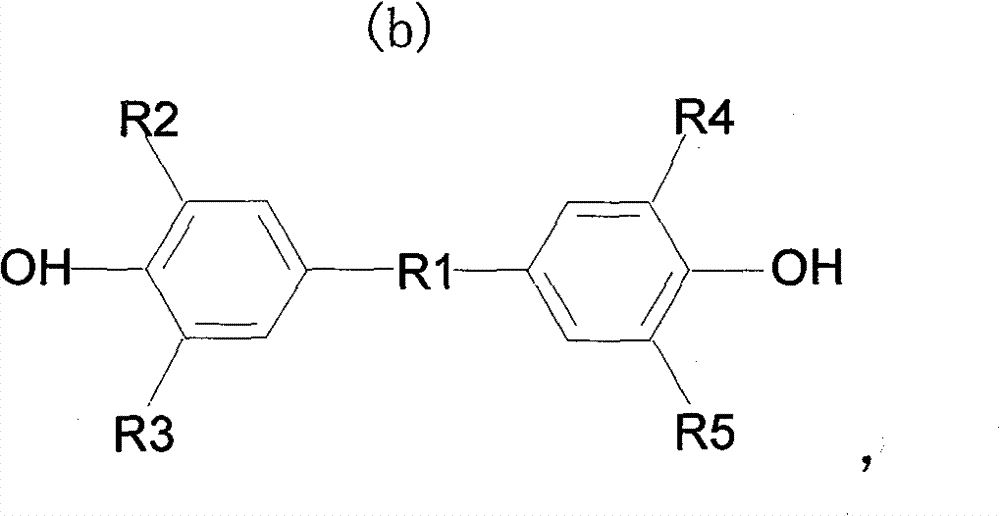

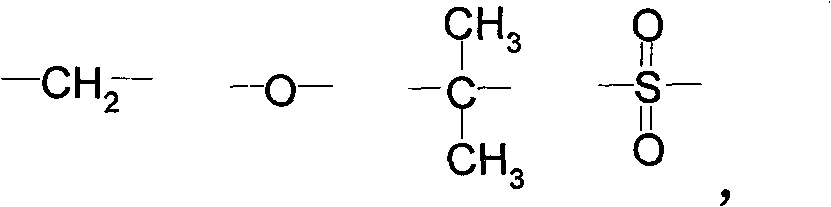

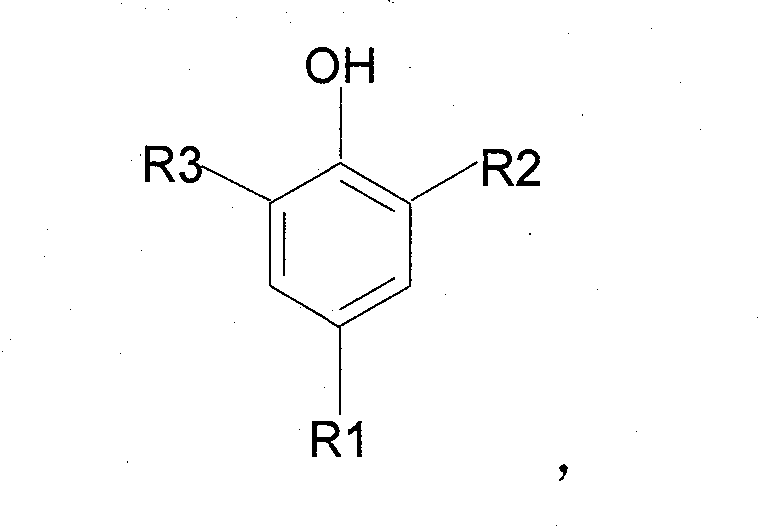

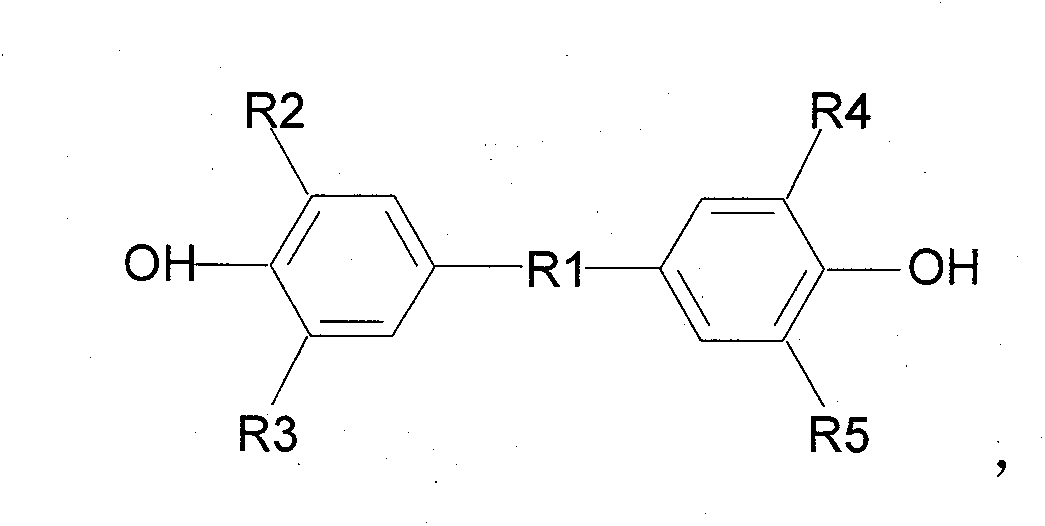

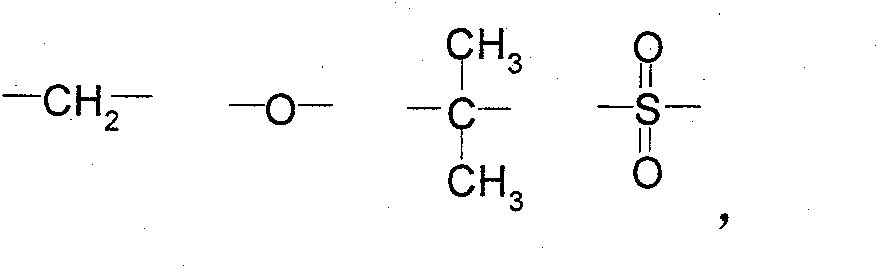

Phosphorus compound and method for preparing the same

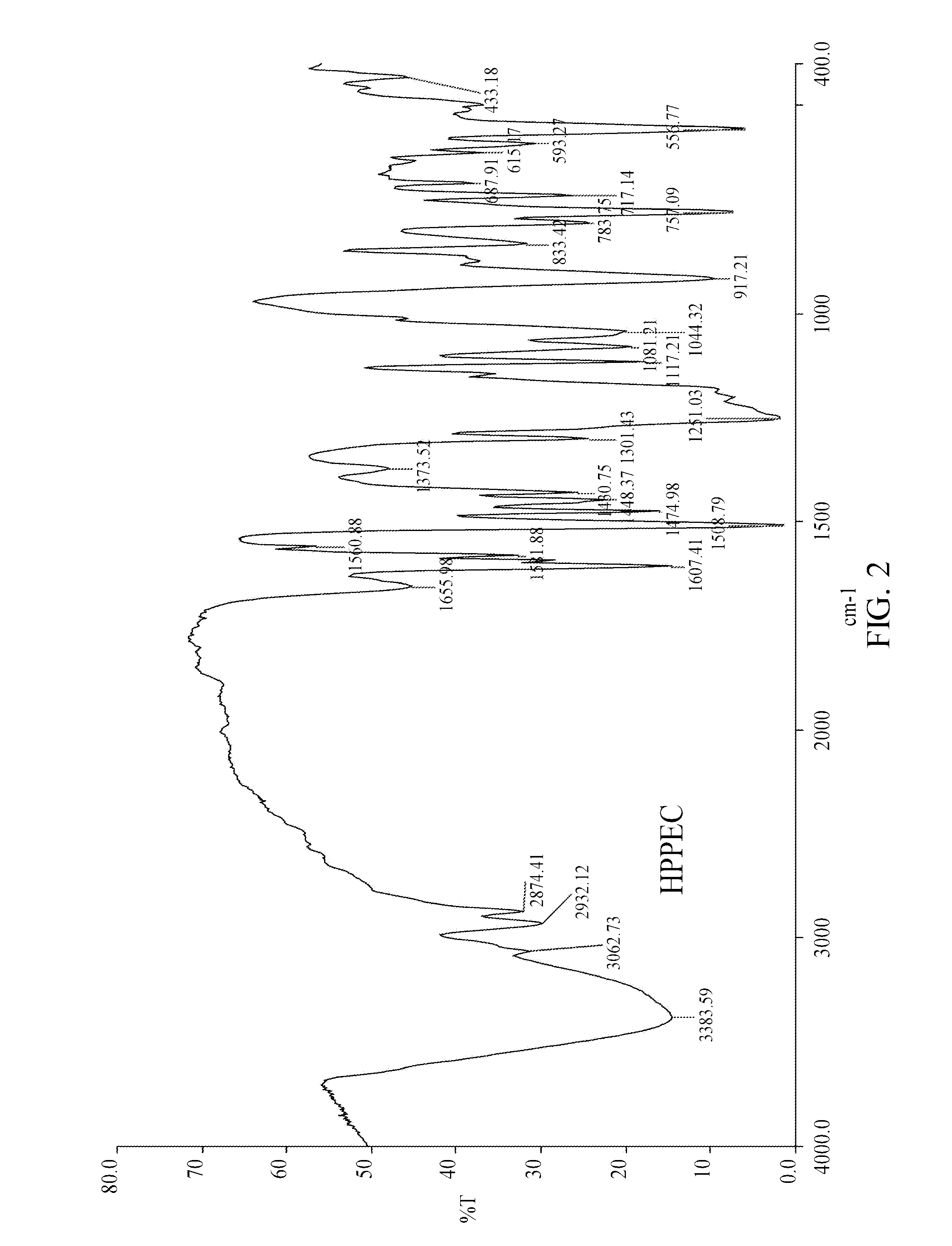

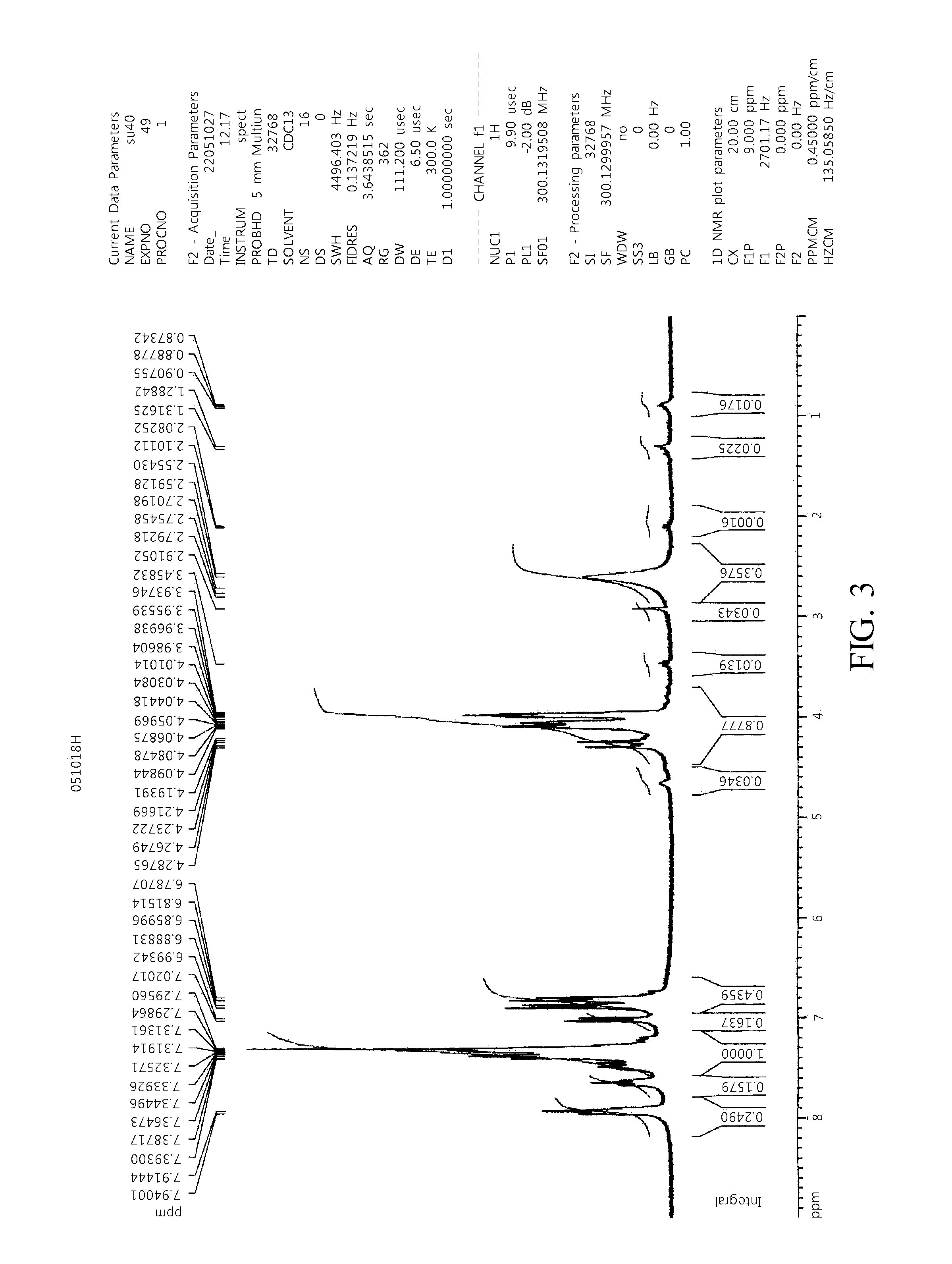

ActiveUS8785696B2Raise the pyrolysis temperatureImprove solubilityPhosphorus organic compoundsSolubilityOrganic solvent

The present invention provides a phosphorus compound of formula (I).The phosphorus compound is prepared by reacting a compound of formula (II) with alkylene carbonate.As compared with the conventional phosphorus compounds as flame-resistant additives, the phosphorus compound of the present invention has not only a high pyrolysis temperature but also excellent solubility in most of the organic solvents with high or low polarity, and is therefore a suitable flame-resistant additive for use in thermosetting or thermoplastic resins.

Owner:CHANG CHUN PLASTICS CO LTD

Low-temperature ozone waste pyrolysis treatment device and method

PendingCN108087884AReduce outputProduces less residual ashIncinerator apparatusOzone generatorCombustion

The invention discloses a low-temperature ozone waste pyrolysis treatment device. The low-temperature ozone waste pyrolysis treatment device comprises a low-temperature ozone waste pyrolysis furnace and an ozone generator. Through ozone combustion supporting, the low-temperature ozone waste pyrolysis treatment device can accelerate the ashing process of household waste, greatly improve the waste treatment efficiency, reduce the waste treatment cost, achieve volume and quantity reduction of household waste, avoid secondary pollution to the environment, achieve low investment, zero pollution andzero emission of household waste.

Owner:福建丰稔环境工程有限公司

Polylactide derivative, method for producing same, and polylactide stereocomplex

A polylactide derivative according to the present invention is expressed by the following general formula (1) or general formula (2):In general formula (1), one of X1-X5 is an aldehyde group, one of the other four is an alkoxy group, and the other three are hydrogen atoms.In general formula (2), one of R1-R3 is selected from a chlorine atom, fluorine atom, aldehyde group, alkoxy group, alkyl group and ester, while the other two are selected from the chlorine atom, fluorine atom, aldehyde group, alkoxy group, alkyl group, ester, and hydrogen atom.

Owner:NARA INSTITUTE OF SCIENCE AND TECHNOLOGY

Production method of blended yarn containing antiflaming polyamide fiber and polyarylester fiber

The invention relates to a production method of blended yarn containing antiflaming polyamide fiber and polyarylester fiber. After antiflaming polyamide fiber combing sliver and polyarylester fiber combing sliver are subjected to two-step drawing procedures to manufacture mixed cooked sliver, the mixed cooked sliver is subjected to the roving step and the spinning step to obtain blended yarn; theantiflaming polyamide fiber combing sliver and the polyarylester fiber combing sliver are each manufactured by antiflaming polyamide fiber and polyarylester fiber through the proprocessing step, the blowing-carding step and the combing step; according to the combing step corresponding to the antiflaming polyamide fiber and the polyarylester fiber, the cylinder combing dread region length is 0-3 mmlarger than the bent hook part average length of the antiflaming polyamide fiber and the polyarylester fiber. The antiflaming polyamide fiber and the polyarylester fiber are blended according to thespecific combing technology, the cylinder combing dead region length in the combing step is controlled, and the manufactured blended yarn has the advantages of being excellent in mechanical performance, anti-flaming performance, anti-dripping performance and the like.

Owner:无锡高仕康新材料科技有限公司

Disk Reactor

ActiveCN106554785BIncrease drying temperatureRaise the pyrolysis temperatureDirect heating destructive distillationDrying gas arrangementsThermodynamicsProcess engineering

The invention discloses a disc type reactor which comprises a drying or pyrolyzing tray (1), a rotation driving device used for driving the tray (1) to rotate and a gas distributing device used for conveying high-temperature gas into the tray (1). The gas distributing device comprises a gas distributing unit which is arranged under the tray (1) and can rotate along with the tray (1) and a hot blast main pipe (2) used for supplying gas to the gas distributing unit. The gas distributing unit communicates with the upper space of the tray (1), and the rotation driving device is located outside the gas distributing device. By adoption of the disc type reactor, higher drying or pyrolyzing temperatures can be obtained, and therefore the disc type reactor can meet pyrolyzing and upgrading requirements of coal of more types, central gas supply is adopted, and the height of a bed can be effectively decreased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

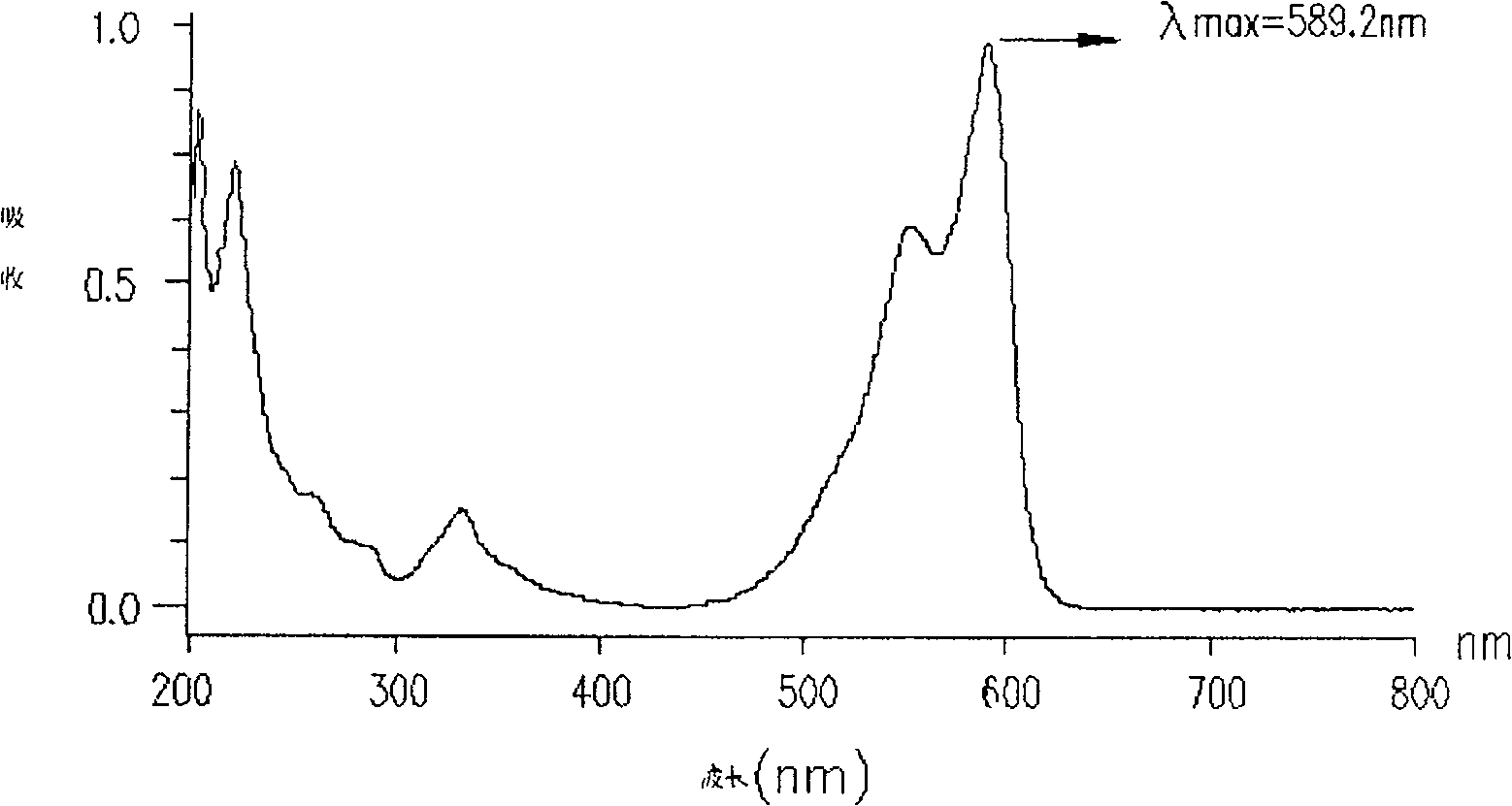

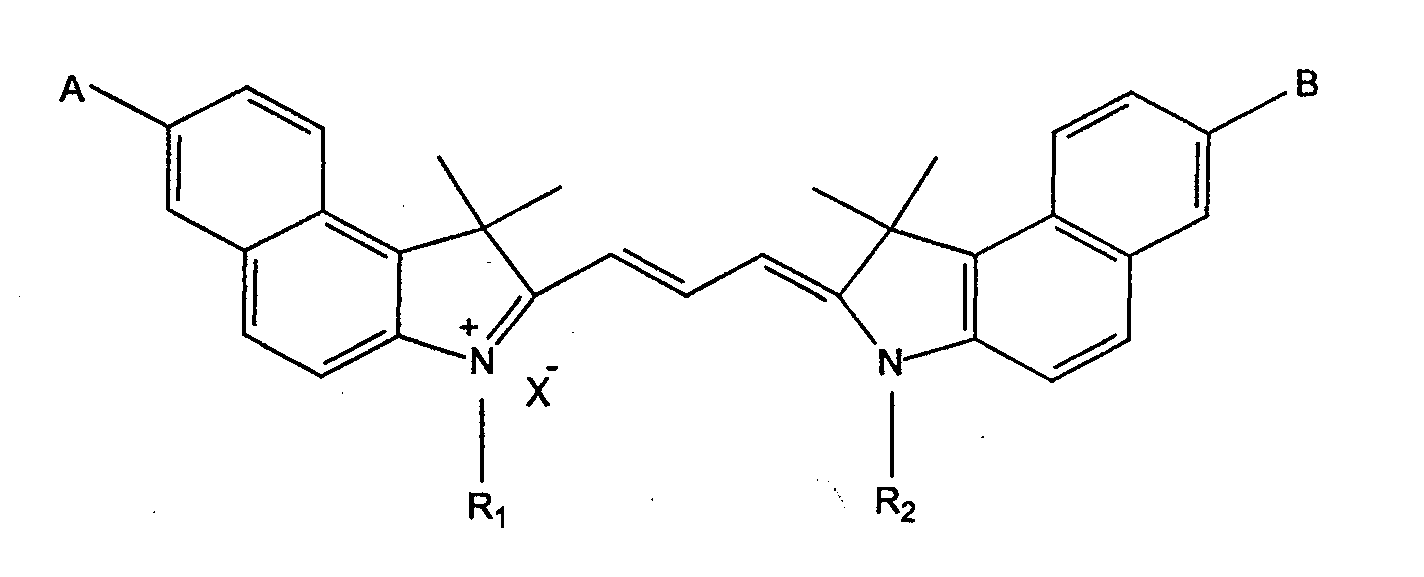

Optical recording medium dye and optical recording medium using same

InactiveCN100424768CRaise the pyrolysis temperatureNot easy to crack/deformMethine/polymethine dyesRecord information storageCyanineHalogen

The invention provides an optical recording medium dye which belongs to the category of cyanine dyestuff with the constitutional formula disclosed in the specification, wherein A, B are the same or different hydrogen atom, halogen or nitrogen containing group, R1, R2 are individual same or different substituted or un-substituted straight chain shaped or branch shaped alkyl, alkene, aralkyl, alkoxycarbonyl, alkoxy, alkylamino, alkoxyalkyl, and X is negative ion.

Owner:RYTEC CORP

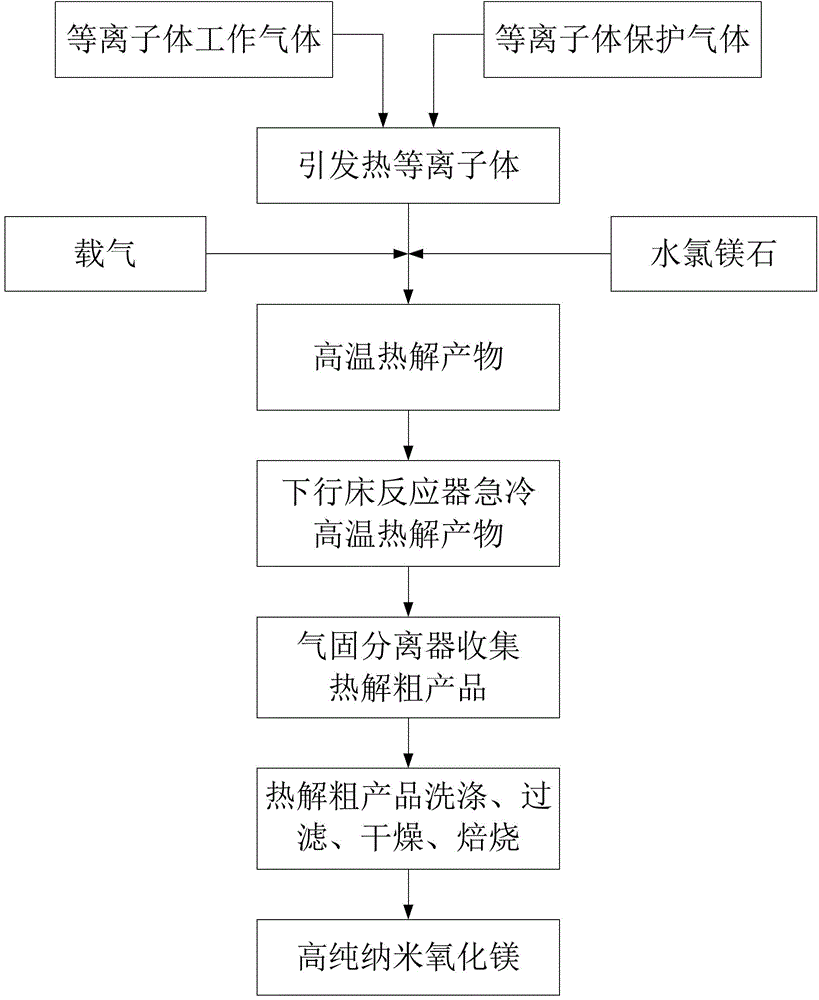

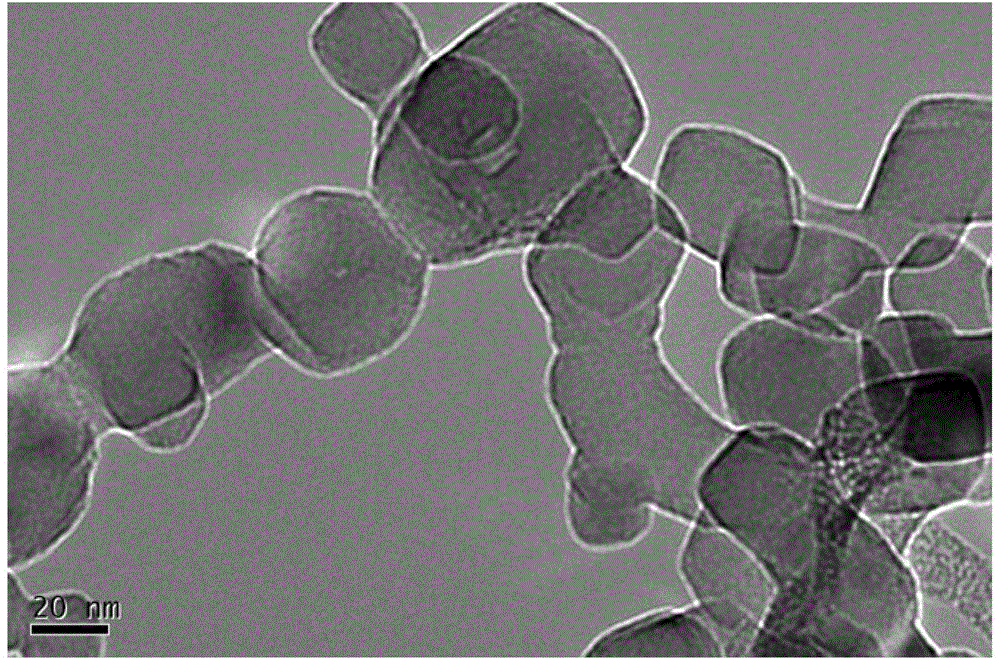

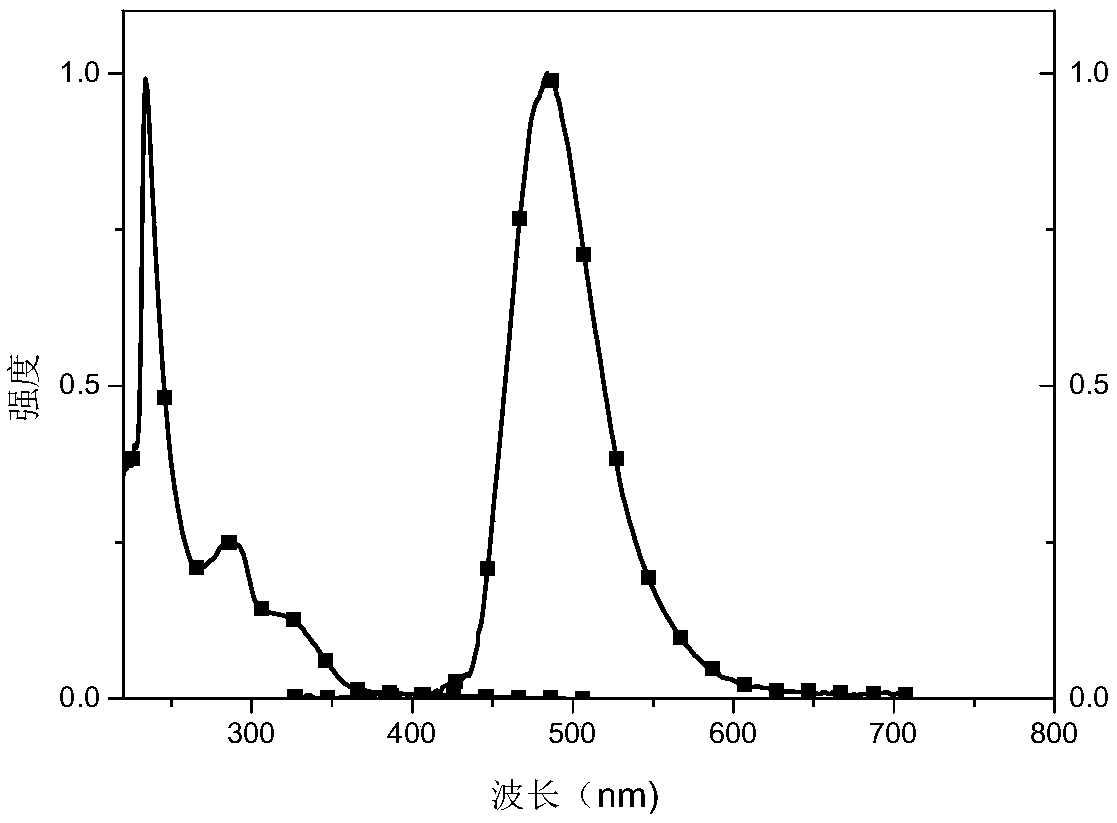

A method for preparing nano-magnesium oxide by plasma high-temperature pyrolysis

ActiveCN103466667BHigh-temperature pyrolysis method is efficient and fastEnhanced pyrolysis processMaterial nanotechnologyMagnesiaBrominePotassium

The invention discloses a method for preparing nanometer magnesium oxide through a plasma high temperature pyrolysis method, which belongs to the technical field of preparation of inorganic nanometer materials. According to the method, bischofite is used as a raw material, a plasma super-high-temperature rapid pyrolysis treatment is carried out on the bischofite, and a pyrolyzed crude product is simply treated to prepare high-purity nanometer magnesium oxide. The preparation method mainly comprises the following steps: triggering thermal plasma, and maintaining the stable operation of the thermal plasma; directly adding the bischofite into a plasma high-temperature arc zone to carry out pyrolysis; quenching a high temperature pyrolysis product and collecting a rough pyrolysis product; washing, filtering, drying and roasting the rough pyrolysis product to obtain the high-purity nanometer magnesium oxide with particle diameter being smaller than 50 nm and Mgo percentage composition being greater than 99%. The method disclosed by the invention can be used in direct pyrolysis of a large amount of bischofite rest after bromine and potassium extraction of salt lake brine, the pyrolysis speed is fast (within milliseconds), no wastewater is generated in the pyrolysis process, the added value of the product is high, the process is simple, and industrialization is easy to realize.

Owner:TSINGHUA UNIV

Thermally activated delayed fluorescence host material, preparation method and applications thereof

ActiveCN108276445AImprove thermal stabilityRaise the pyrolysis temperatureGroup 5/15 element organic compoundsSolid-state devicesFluorescenceElectricity

The present invention provides a thermally activated delayed fluorescence host material, a preparation method and applications thereof, wherein a thermally activated delayed fluorescence material based on 9,10-dihydro-9,10-o-benzo-9,10-diphospha anthracene-9,10-dioxide is used as a precursor and is modified with different amounts of fluorine atoms so as to prepare the thermally activated delayed fluorescence host material. According to the present invention, the thermally activated delayed fluorescence electroluminescent device prepared by using the thermally activated delayed fluorescence host material as the electroluminescent material has the turn-on voltage of less than 3.0 V, the maximum external quantum efficiency of higher than 12%, the maximum current efficiency of greater than 25cd.A<-1>, and the maximum power efficiency of greater than 20 lm.W<-1>.

Owner:HEILONGJIANG UNIV

A novel triazole fluorescent coordination polymer and its preparation method and application

InactiveCN103588797BHigh molecular weightImprove thermal stabilityFluorescence/phosphorescenceEnergy efficient lightingSpace groupLuminous intensity

The invention discloses a novel triazole fluorescent coordination polymer and a preparation method and application thereof, and belongs to the technical field of organic synthesis. The chemical formula of the novel triazole fluorescent coordination polymer is Zn(C9H6O4)(C7H10N6).(H2O)2, the novel triazole fluorescent coordination polymer belongs to monoclinic crystal systems and has a space group of P21 / c(No.14), and has cell parameters: alpha is equal to gamma and is equal to 90 degrees, and beta is equal to 110.9890 (10) degrees; the novel triazole fluorescent coordination polymer uses Zn (OAc)2.2H2O, 5-methyl isophthalic acid and 1,3-bis(1, 2, 4-triazolo)-propane as reactants, and is prepared by a hydrothermal method. The novel triazole fluorescent coordination polymer is good in thermal stability and high in luminous intensity, is a new product synthesized in a laboratory, and is simple in preparation method and wide in application.

Owner:HUAINAN NORMAL UNIV

Small-sized three-dimensional garbage incinerator with combustion chambers

InactiveCN112594703ARaise the pyrolysis temperatureFully pyrolyzedIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberFlue gas

The invention discloses a small-sized three-dimensional garbage incinerator with combustion chambers. The periphery of a first combustion chamber is used as a second combustion chamber, so that heat loss of the first combustion chamber is avoided, and the pyrolysis temperature of the first combustion chamber can be increased; the periphery of the second combustion chamber is used as a combustion air preheating layer, so that heat loss of the second combustion chamber is avoided, meanwhile, combustion air is heated, and combustion supporting and temperature rise of the first combustion chamberand the second combustion chamber are facilitated; high-temperature flue gas from the second combustion chamber passes through an air cooling heat exchanger, the combustion air is heated by the heat exchanger, so that part of heat in the flue gas is replaced, and the flue gas enters the air preheating layer, the first combustion chamber and the second combustion chamber in the tangential directionrespectively; heat generated by garbage incineration is conveyed back into the incinerator to the maximum extent, so that the heat in the first combustion chamber and the second combustion chamber isaccumulated continuously, the first combustion chamber and the second combustion chamber do not need combustion supporting any more, and stable operation can be realized; and therefore, energy is saved, and the operating cost is reduced.

Owner:SICHUAN TIANYI ENVIRONMENTAL PROTECTION CO LTD

Thermosetting resin composition and use

InactiveCN101481490BLow dielectric propertiesImprove toughnessCircuit susbtrate materialsMetal layered productsGlass fiberPolymer science

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com