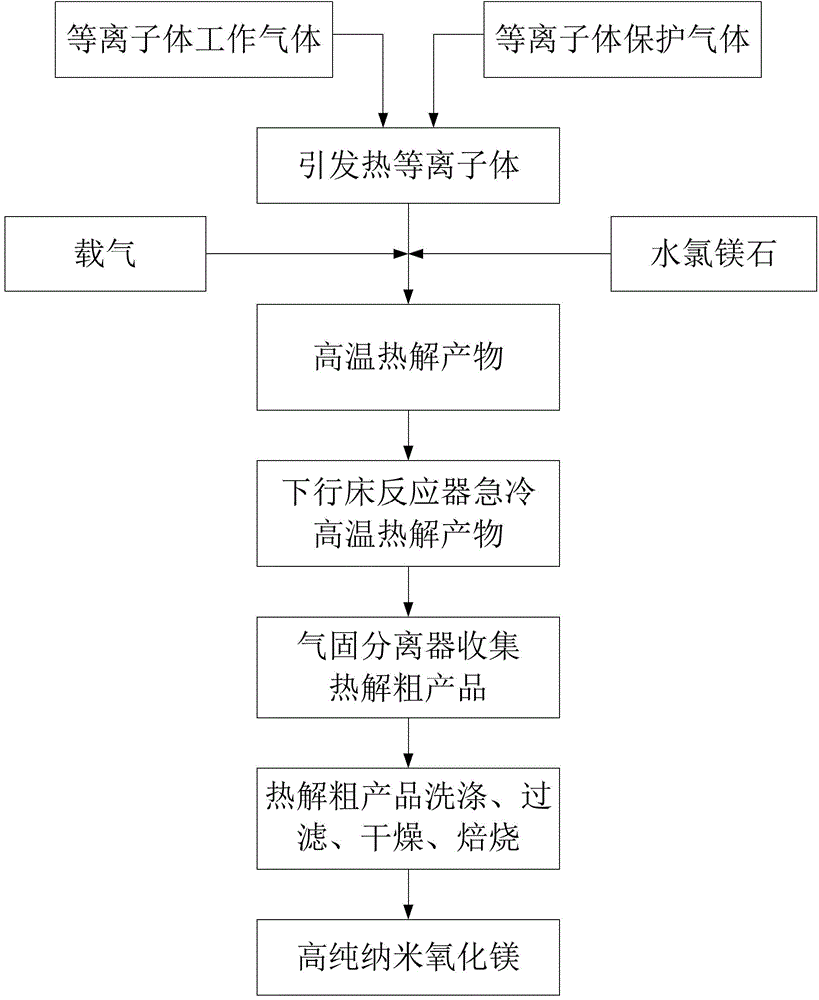

A method for preparing nano-magnesium oxide by plasma high-temperature pyrolysis

A nano-magnesium oxide, plasma technology, applied in magnesium oxide, nanotechnology for materials and surface science, nanotechnology and other directions, can solve the problems of long cycle, low pyrolysis efficiency, high energy consumption, etc., and achieve fast heating speed , the effect of high pyrolysis temperature and simple pyrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

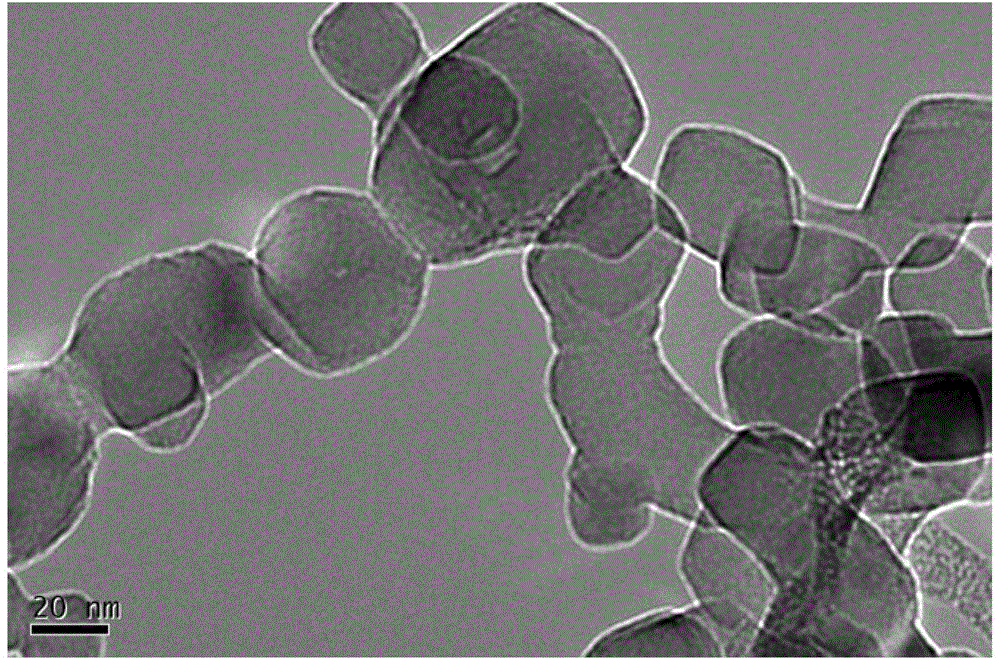

Embodiment 1

[0038] Using argon as the working gas and shielding gas, the flow rates are 0.2m 3 / h and 4m 3 / h, pass it into the radio frequency plasma torch, trigger the thermal plasma, the plasma power is 10kW, and form the plasma high temperature arc area. With oxygen as carrier gas, the flow rate is 0.1m 3 / h, using the remaining bischofite solution after extracting bromine and potassium from salt lake brine as raw material, concentrated to MgCl 2 The percentage content is 35%, and the insoluble impurities are removed by filtration. The bischofolite solution is sprayed into the plasma high-temperature arc area through the feeding spray gun at a feed rate of 1ml / min by an advection pump to form high-temperature pyrolysis products. The high-temperature pyrolysis product enters the water-cooled down-bed reactor for rapid cooling, and the outlet temperature is 245°C. A gas-solid separator is used to collect solid materials in the gas-solid mixture after quenching to obtain pyrolysis cru...

Embodiment 2

[0040] With helium as the working gas, the flow rate is 0.2m 3 / h, the air is the protective gas, the flow rate is 4m 3 / h, pass it into the radio frequency plasma torch, trigger the thermal plasma, the plasma power is 10kW, and form the plasma high temperature arc area. With argon as carrier gas, the flow rate is 0.1m 3 / h, using the remaining bischofite solution after extracting bromine and potassium from salt lake brine as raw material, concentrated to MgCl 2 The percentage content is 40%, and the insoluble impurities are removed by filtration. The bischofolite solution is sprayed into the plasma high-temperature arc area through the feeding spray gun at a feed rate of 2ml / min by an advection pump to form high-temperature pyrolysis products. The high-temperature pyrolysis product enters the water-cooled down-bed reactor for rapid cooling, and the outlet temperature is 100°C. A gas-solid separator is used to collect solid materials in the gas-solid mixture after quenching...

Embodiment 3

[0042] Using argon as the working gas, the flow rate is 0.2m 3 / h, oxygen is the protective gas, the flow rate is 4m 3 / h, pass it into the radio frequency plasma torch, trigger the thermal plasma, the plasma power is 10kW, and form the plasma high temperature arc area. With air as carrier gas, the flow rate is 0.1m 3 / h, using the remaining bischofite solution after extracting bromine and potassium from salt lake brine as raw material, concentrated to MgCl 2 The percentage content is 40%, and the insoluble impurities are removed by filtration. The bischofolite solution is sprayed into the plasma high-temperature arc area through the feeding spray gun at a feed rate of 1ml / min by an advection pump to form high-temperature pyrolysis products. The high-temperature pyrolysis products enter the water-cooled down-bed reactor for rapid cooling, and the outlet temperature is 200°C. A gas-solid separator is used to collect solid materials in the gas-solid mixture after quenching to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com