Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

A technology for lithium-ion batteries and piezoelectric materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of destroying the bulk phase structure of positive active materials, thermal safety of materials with slow ion diffusion, and declining material structure stability. , to achieve the effect of improving the diffusion rate, improving the structural stability and electrochemical cycle performance, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

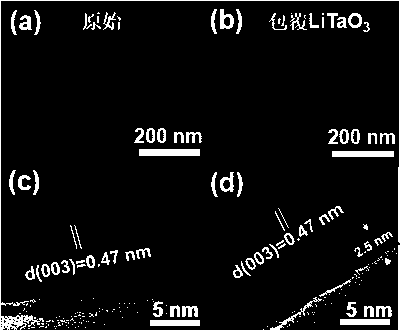

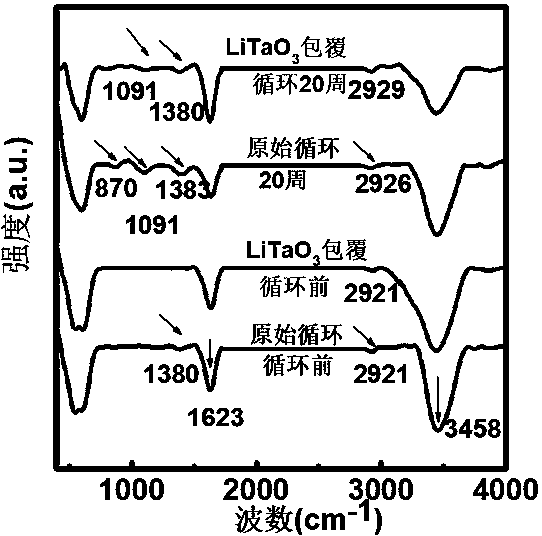

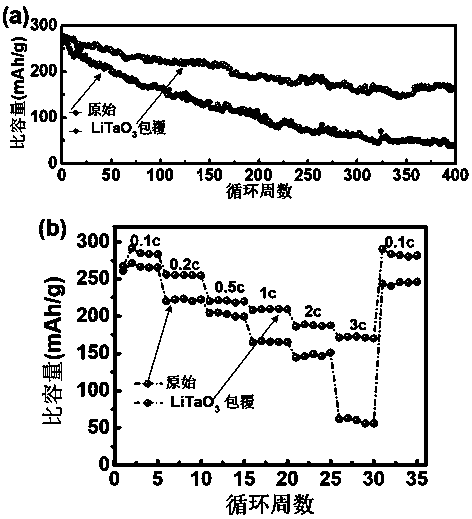

[0041] Piezoelectric material LiTaO 3 Coated lithium-ion battery lithium-rich cathode material Li 1.2 mn 0.56 Ni 0.17 co 0.07 o 2 .

[0042] (1) Configure 0.1 M Ta 2 o 5 、C 4 h 6 o 6 and CH 3 COOLi was dissolved in ethanol solution, selected according to the proportion, dropped into the positive electrode material solution dissolved in ethanol, and then mixed and stirred for 8 h;

[0043] (2) The above mixed solution was heated to 100 °C, stirred and evaporated, and then dried in a drying oven at 120 °C for 12 h to obtain a xerogel;

[0044] (3) Put the above dry gel into a crucible after being ground, calcined at 500 °C for 48 h, and naturally cooled to room temperature to obtain the piezoelectric material LiTaO 3 coated lithium-rich cathode material.

Embodiment 2

[0046] Piezoelectric material BaTiO 3 Coated lithium-ion battery lithium-rich cathode material Li 1.2 mn 0.56 Ni 0.17 co 0.07 o 2 .

[0047] (1) Configure 0.1 M of Ba 2 CO 3 、C 6 h 8 o 7 and C 16 h 36 CO 4 Ti is dissolved in the ethanol solution, selected according to the ratio, dropped into the positive electrode material solution dissolved in ethanol, and then mixed and stirred for 10 h;

[0048] (2) The above mixed solution was heated to 80 °C, stirred and evaporated, and then dried in an oven at 80 °C for 12 h to obtain a xerogel;

[0049] (3) The above dry gel was ground and put into a crucible, calcined at 900 °C for 12 h, and then naturally cooled to room temperature to obtain the piezoelectric material BaTiO 3 coated lithium-rich cathode material.

Embodiment 3

[0051] Piezoelectric material LiNbO 3 Coated Lithium Iron Phosphate Cathode Material LiFePO for Lithium-ion Batteries 4 .

[0052] (1) Configure Nb of 0.1 M 2 o 5 、C 4 h 6 o 6 and CH 3 COOLi was dissolved in ethanol solution, selected according to the proportion, dropped into the positive electrode material solution dissolved in ethanol, and then mixed and stirred for 8 h;

[0053] (2) The above mixed solution was heated to 120 °C, stirred and evaporated, and then dried in a drying oven at 120 °C for 12 h to obtain a xerogel;

[0054] (3) Put the above dry gel into a crucible after being ground, calcined at 550 °C for 24 h, and naturally cooled to room temperature to obtain the piezoelectric material LiNbO 3 Coated lithium iron phosphate cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com