Optical recording medium dye and optical recording medium using same

A technology for optical recording and media, which is applied in the direction of optical recording carrier, optical recording/reproduction, organic dyes, etc. It can solve the problems of incorrect data, destruction, low cracking temperature and thermal resistance, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0027]

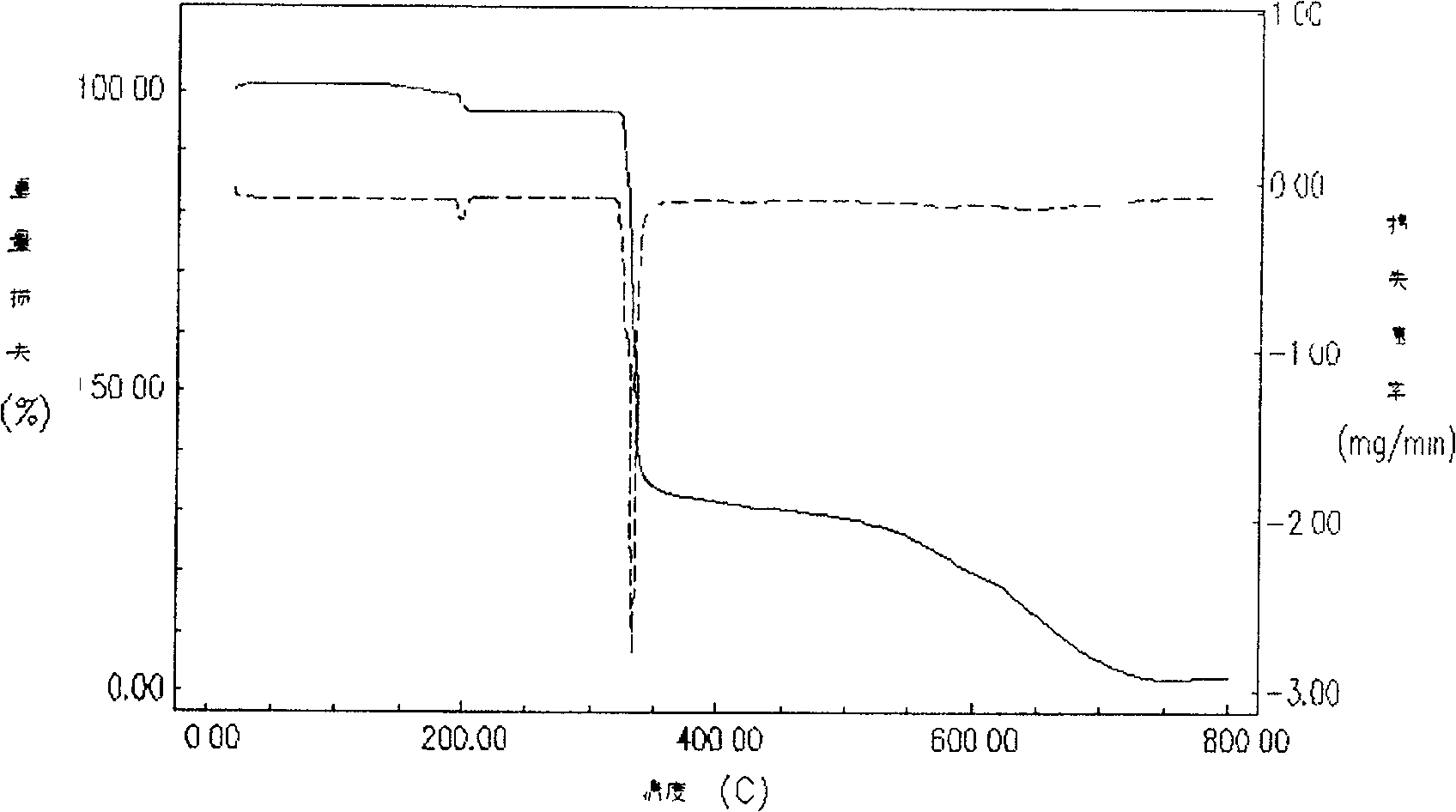

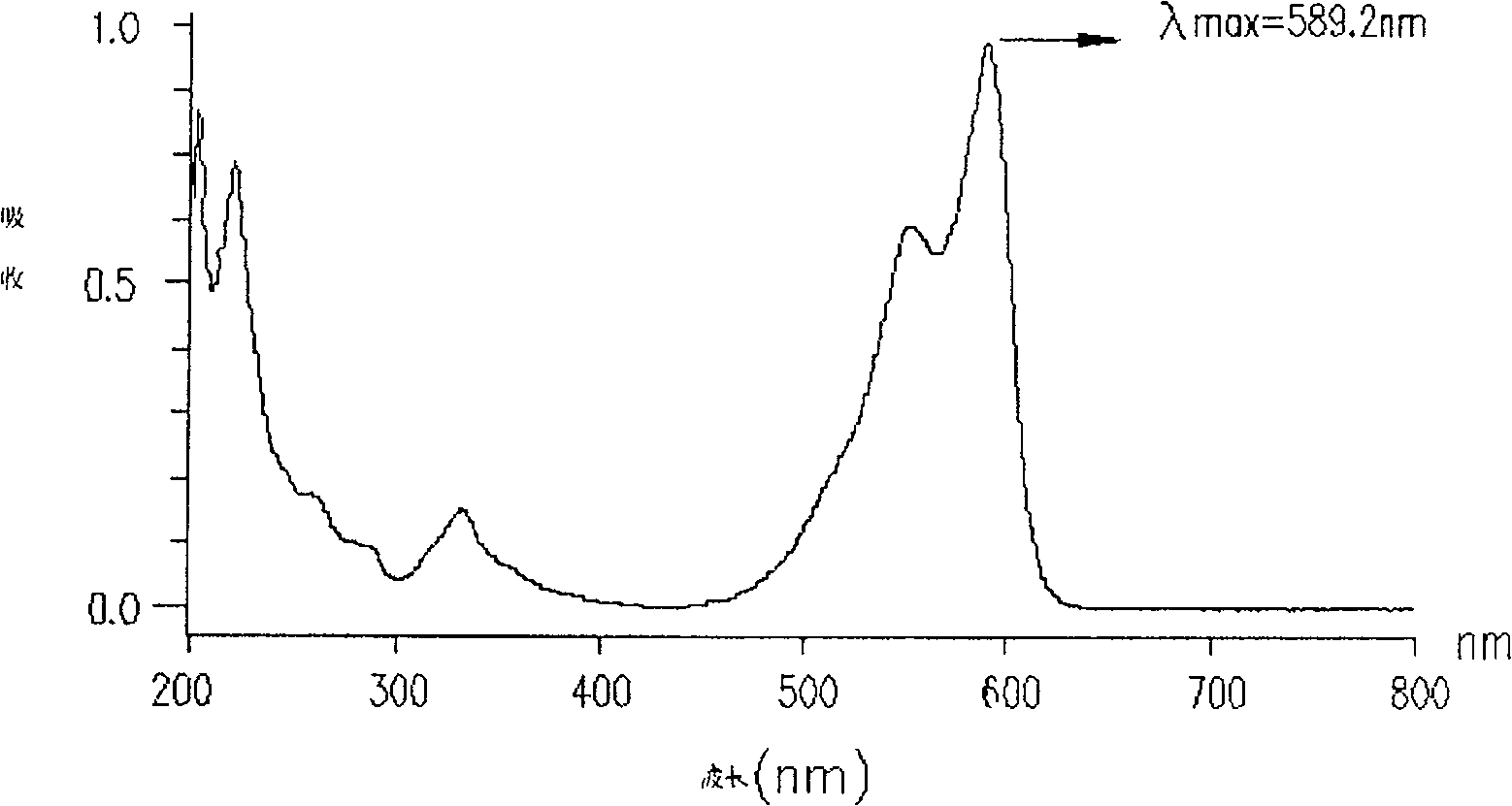

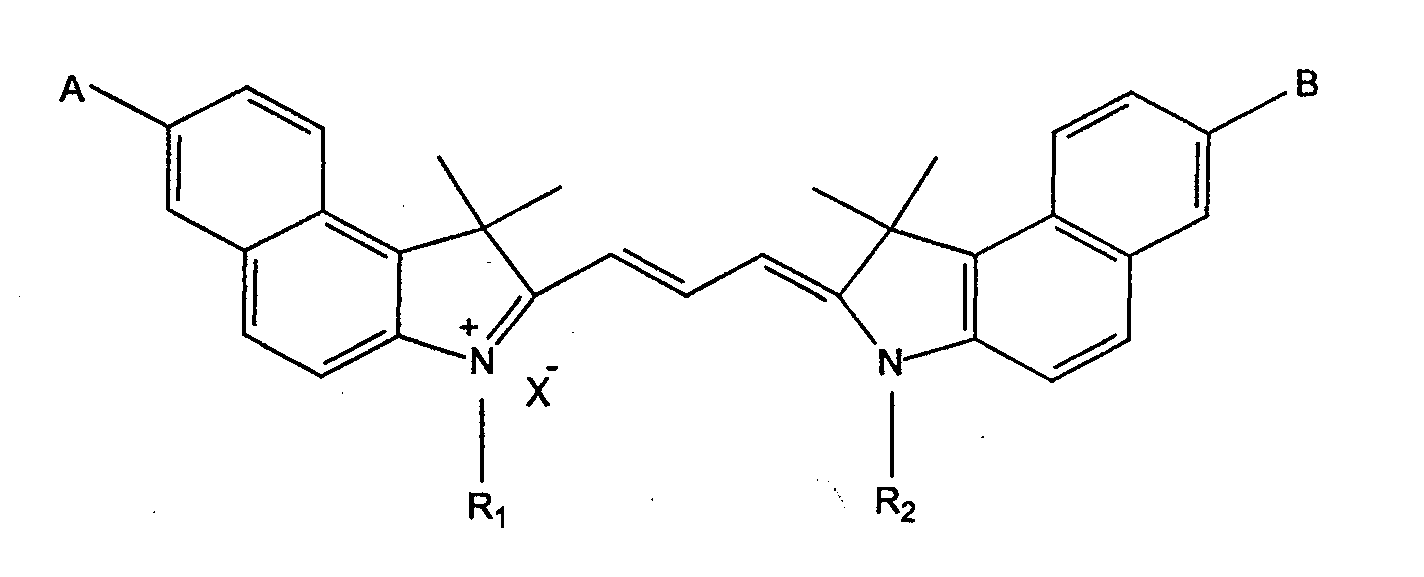

[0028] Add 5 grams of iodide 1-methyl-2.3.3-trimethyl-6-bromo-benzo[e]indole (1-methyl-2.3.3-trimethyl-6-bromo- benzo[e]indolium iodide), 0.85 g of triethyl orthoformate and 10 ml of pyridine, heated to reflux at 120° C. for 3 hours, and then cooled the reaction to room temperature. 50 ml of 6N hydrochloric acid and 250 ml of distilled water were mixed in a beaker, and the aforementioned reaction solution was slowly poured into the beaker, and stirred for 8 hours. The mixture was filtered to obtain the dye, and the dye was washed several times with distilled water, and the obtained dye was bis(1-methyl-3.3-dimethyl-6-bromo-benzo[e]indole)-2 iodide: 2'-propylmethine (bis(1-methyl-3.3-dimethyl-6-bromo-benzo[e]indo)-2: 2'-propylmethineiodide) 2.6 g. The aforementioned dyes were placed in a round bottom bottle, and 5.2 g of potassium fluorophosphate (KPF 6 ) and 30 ml of methanol, and after stirring for 24 hours, the crystals can be obtained by filtration, and the res...

experiment example 2

[0031]

[0032]Add 4.6 grams of 1-butyl-2.3.3-trimethyl-6-bromo-benzo[e]indole iodide (1-butyl-2.3.3-trimethyl-6-bromo-benzo [e]indolium iodide), 5 grams of 1-butyl-2-(anilinovinyl)-3.3-dimethyl-benzo[e]indole (1-butyl-2-(anilinovinyl)-3.3- dimethyl-benzo[e]indolium iodide), 10 ml of pyridine, 2.4 ml of glacial acetic acid, and 2.5 ml of triethylamine. After heating to reflux for 3 hours, the reaction was allowed to cool to room temperature. 50 ml of 6N hydrochloric acid and 250 ml of distilled water were mixed in a beaker, and the aforementioned reaction solution was slowly poured into the beaker, and stirred for 8 hours. Filter the mixture to obtain the dye, and rinse the dye several times with distilled water to obtain 1-butyl-3.3-dimethyl-1'-butyl-3'.3'-dimethyl-6 iodide '-Bromo-bis-benzo[e]indole)-2:2'-propylmethine (1-butyl-3.3-dimethyl-1'-butyl-3'.3'-dimethyl-6'-bromo- bis-benzo[e]indo-2: 2'-propylmethine iodide) 3.1 g. Place the aforementioned dye in a round bott...

experiment example 3

[0035]

[0036] The cyanine dyes prepared in Experimental Example 1 and Experimental Example 2 were respectively dissolved in 10 ml of Tetrafluoropropane, and filtered through filter paper with a pore size of 0.25 μm to obtain a filtrate. Take 5ml of the filtrate and spin-coat (spin on coating), and spin-coat it on a polycarbonate resin substrate with a diameter of 12 cm rotating at a speed of 500 rpm to form a coating layer as the recording layer of the optical recording medium, and the above-mentioned substrate The surface of has groove tracks with a depth of 160 nm and a width of 0.3 μm. The above-mentioned substrate with the optical dye coating layer was then dried at a temperature of 85° C. for 20 minutes.

[0037] Next, a gold (Gold) layer with a thickness of 100nm is plated on the recording layer by sputtering as a reflective layer, and then a layer of UV-curable resin is spin-coated on the reflective layer by spin coating , and irradiate the UV curable resin layer w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com