Oil shale and coal interbed collaborative in-situ mining method

An in-situ mining and oil shale technology, applied in the fields of fluid extraction, coal gasification, earthwork drilling, etc., can solve problems such as resource waste and environmental pollution, reduce resource waste, improve pyrolysis efficiency and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

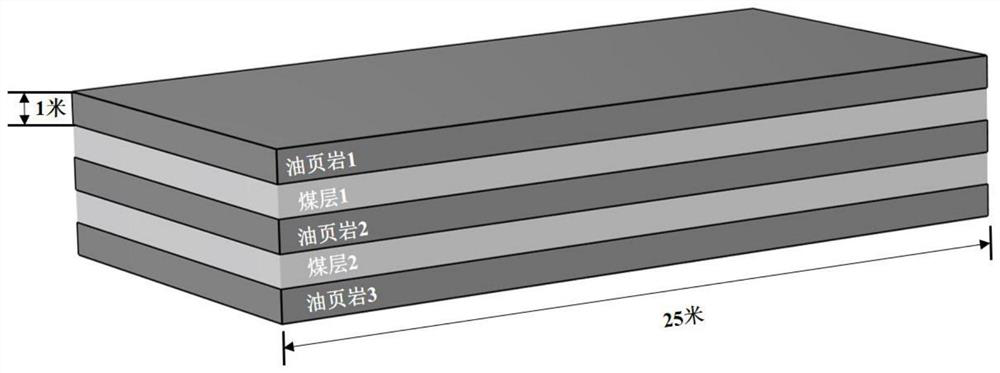

[0039] (1) Judging the burial depth of interbedded oil shale and coal, as well as the associated interface of the two, through the logging interpretation curve, such as figure 1 shown;

[0040] (2) Through the coaxial cable, the microwave generated on the ground is transmitted to the underground;

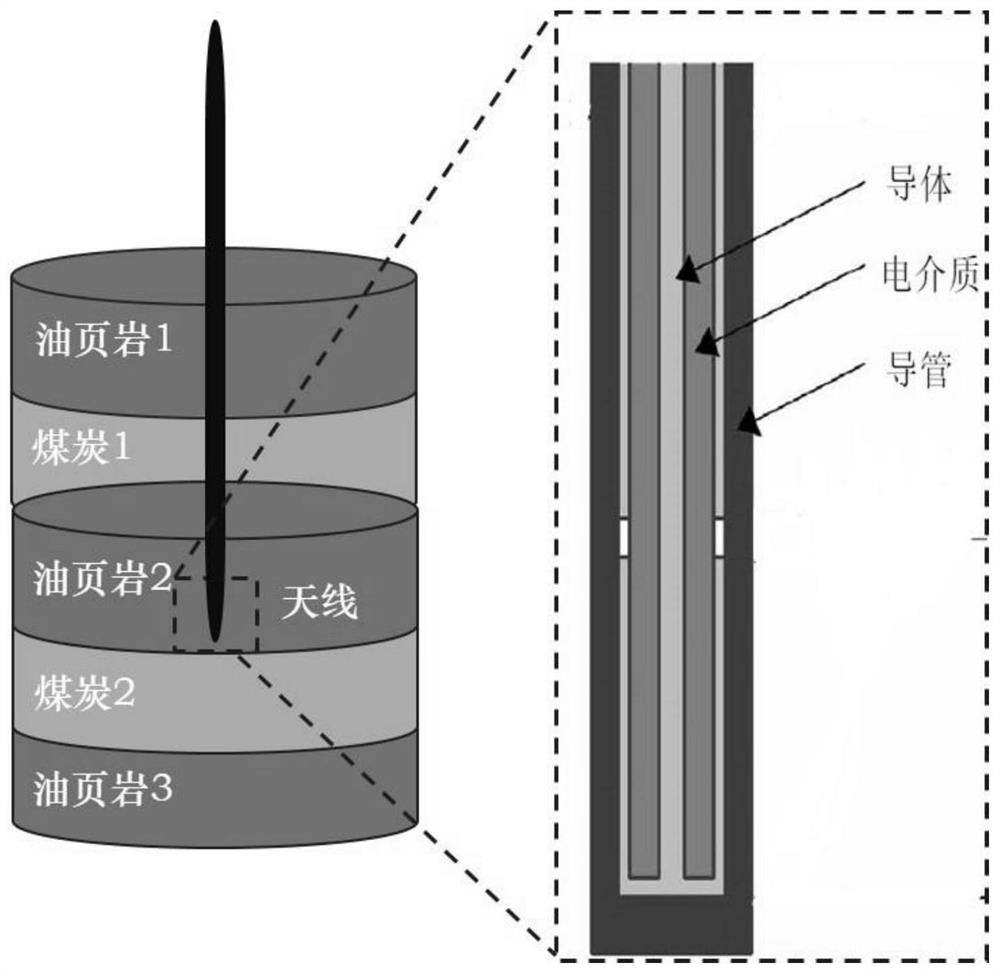

[0041] (3) see figure 2 ( figure 2 The right side is the schematic diagram of the antenna installed in the wellbore), and the microwave antenna is aimed at the oil shale layer 2 in the middle layer (because the pyrolysis temperature of oil shale is higher than the low-temperature pyrolysis temperature of coal seam, the oil shale can be used to Heating and co-pyrolysis of the nearby coal seam in the high temperature area), turning on the microwave source, and radiating heating of the oil shale;

[0042] Specifically, the power of the microwave emission source is set to 400W, and the electric field strength can reach a maximum value of 2310V / m;

[0043] (4) Heat the oil shale to...

Embodiment 2

[0049] (1) Judging the burial depth of interbedded oil shale and coal, as well as the associated interface of the two, through the logging interpretation curve, such as figure 1 shown;

[0050] (2) Through the coaxial cable, the microwave generated on the ground is transmitted to the underground;

[0051] (3) Aim the antenna of the microwave at the first layer of the coal seam in the middle layer, turn on the microwave source, and carry out radiation heating to the oil shale;

[0052] Specifically, the power of the microwave emission source is set to 400W, and the electric field strength can reach a maximum value of 2310V / m;

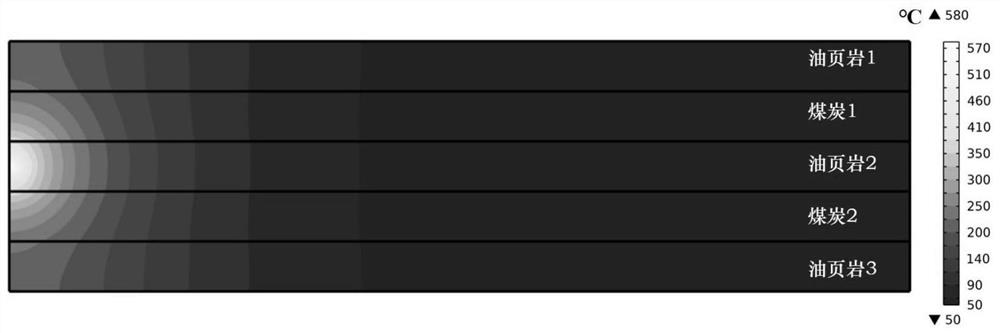

[0053] Using continuous heating for 30 days, the maximum temperature of the coal seam is 489°C, the maximum temperature of the oil shale layer 1 is 169°C, and the maximum temperature of the oil shale layer 3 is 164°C. Line cloud chart see image 3 ;

[0054] From Figure 4 It can be seen that if the microwave is naturally aimed at the coal seam, alt...

Embodiment 3

[0056] (1) Judging the burial depth of interbedded oil shale and coal, as well as the associated interface of the two, through the logging interpretation curve, such as figure 1 shown;

[0057] (2) Through the coaxial cable, the microwave generated on the ground is transmitted to the underground;

[0058] (3) see figure 2 , aim the microwave antenna at the oil shale layer 2 in the middle layer (because the oil shale pyrolysis temperature is higher than the low temperature pyrolysis temperature of the coal seam, the high temperature area of the oil shale can be used to heat the nearby coal seam Solution), turn on the microwave source, and carry out radiation heating to the oil shale;

[0059] Specifically, the power of the microwave emission source is set to 600W, and the electric field strength can reach a maximum value of 2830V / m;

[0060] (4) Heat the oil shale to the pyrolysis temperature, monitor the temperature of the oil shale near the wellbore with a downhole temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com