Composition of thermosetting resin and copper foil laminated plate

A thermosetting and resin technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of poor flame resistance, environmental pollution, low dielectric constant dissipation coefficient, etc., and achieve low dissipation coefficient, low Dielectric constant, the effect of overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

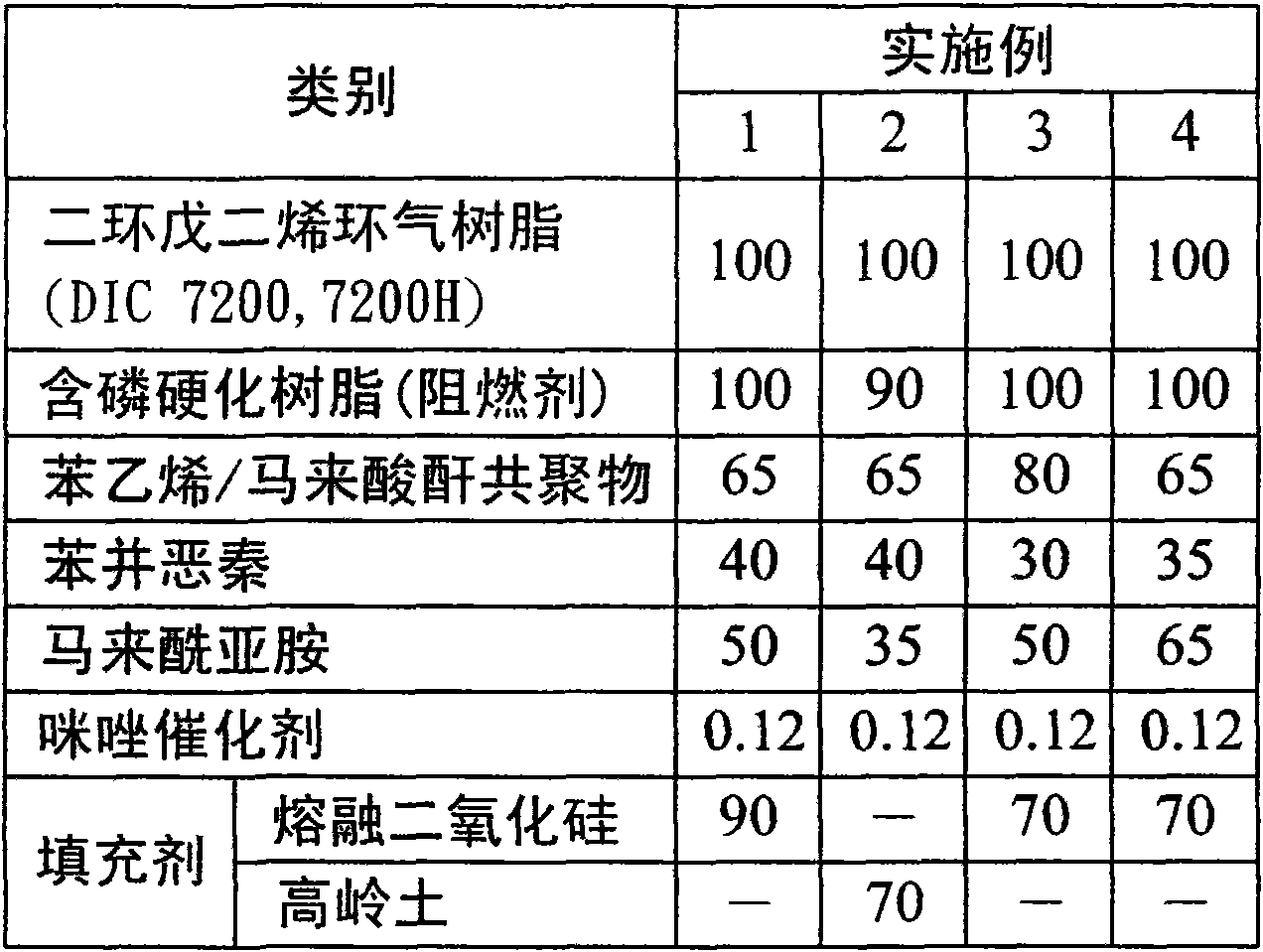

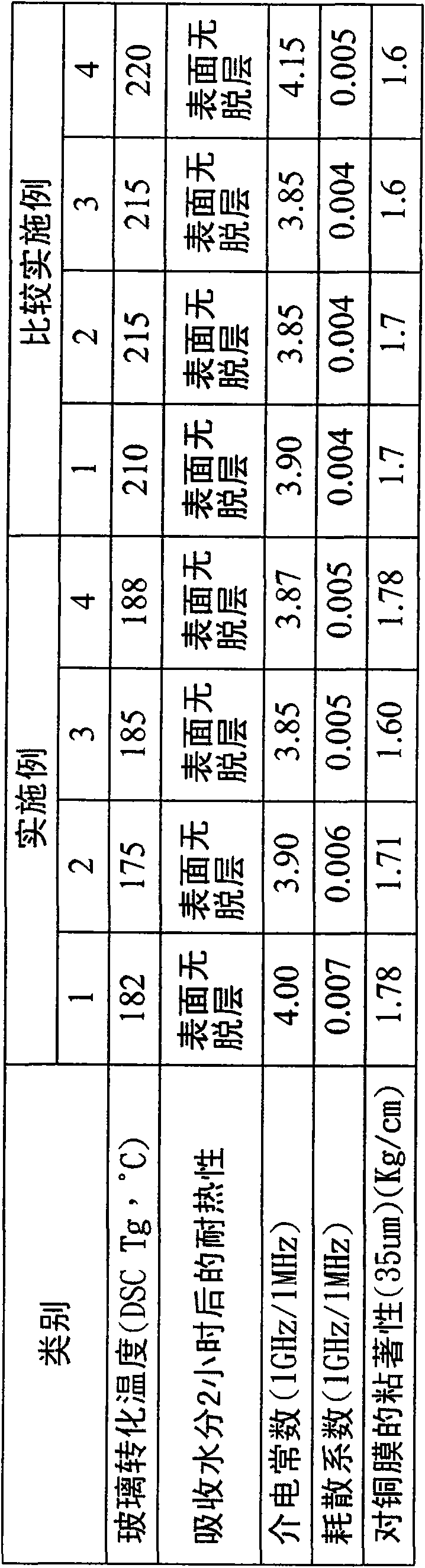

[0048] The composition of the thermosetting resin used in this example contains 100 parts by weight of dicyclopentadiene epoxy resin, 100 parts by weight of phosphorus-containing hardening resin as a flame retardant, 65 parts by weight of styrene / maleic anhydride copolymer, 40 parts by weight of benzoxazine, 50 parts by weight of maleimide, 0.12 parts by weight of imidazole catalyst, and 90 parts by weight of fused silica were used as fillers.

[0049] The fiber cloth is immersed in the solution containing the composition of this thermosetting resin. Then, the fiber cloth was dried at a temperature of 110 to 195° C. to prepare an adhesive sheet for a printed circuit board having a B state. Then, the top and bottom of the adhesive sheet were covered with a copper foil sheet with a thickness of 35 μm, and heated and pressed with a vacuum press to prepare the copper foil laminate for high-speed signal transmission of Example 1.

Embodiment 2

[0051] Different from Example 1, the content of maleimide in the composition of the thermosetting resin was changed from 50 parts by weight to 35 parts by weight, and the filler was changed to 70 parts by weight of kaolin. The rest were in the same manner as in Example 1 to prepare the composition of the thermosetting resin and the copper foil laminate for high-speed signal transmission.

Embodiment 3

[0053] Different from Example 1, in the composition of thermosetting resin, the content of styrene / maleic anhydride copolymer was changed from 65 parts by weight to 80 parts by weight, the content of benzoxazine was changed from 40 parts by weight to 30 parts by weight, and the melting The content of silica was changed from 90 parts by weight to 70 parts by weight. The rest were in the same manner as in Example 1 to prepare the composition of the thermosetting resin and the copper foil laminate for high-speed signal transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com