Method for treating leachate from waste incineration plants

A treatment method and technology of waste incineration, applied in the direction of contaminated groundwater/leachate treatment, permeation/dialysis water/sewage treatment, multi-stage water treatment, etc. Large land area, large energy consumption and other problems, to achieve the effect of reducing investment and operating costs, reducing operating costs, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

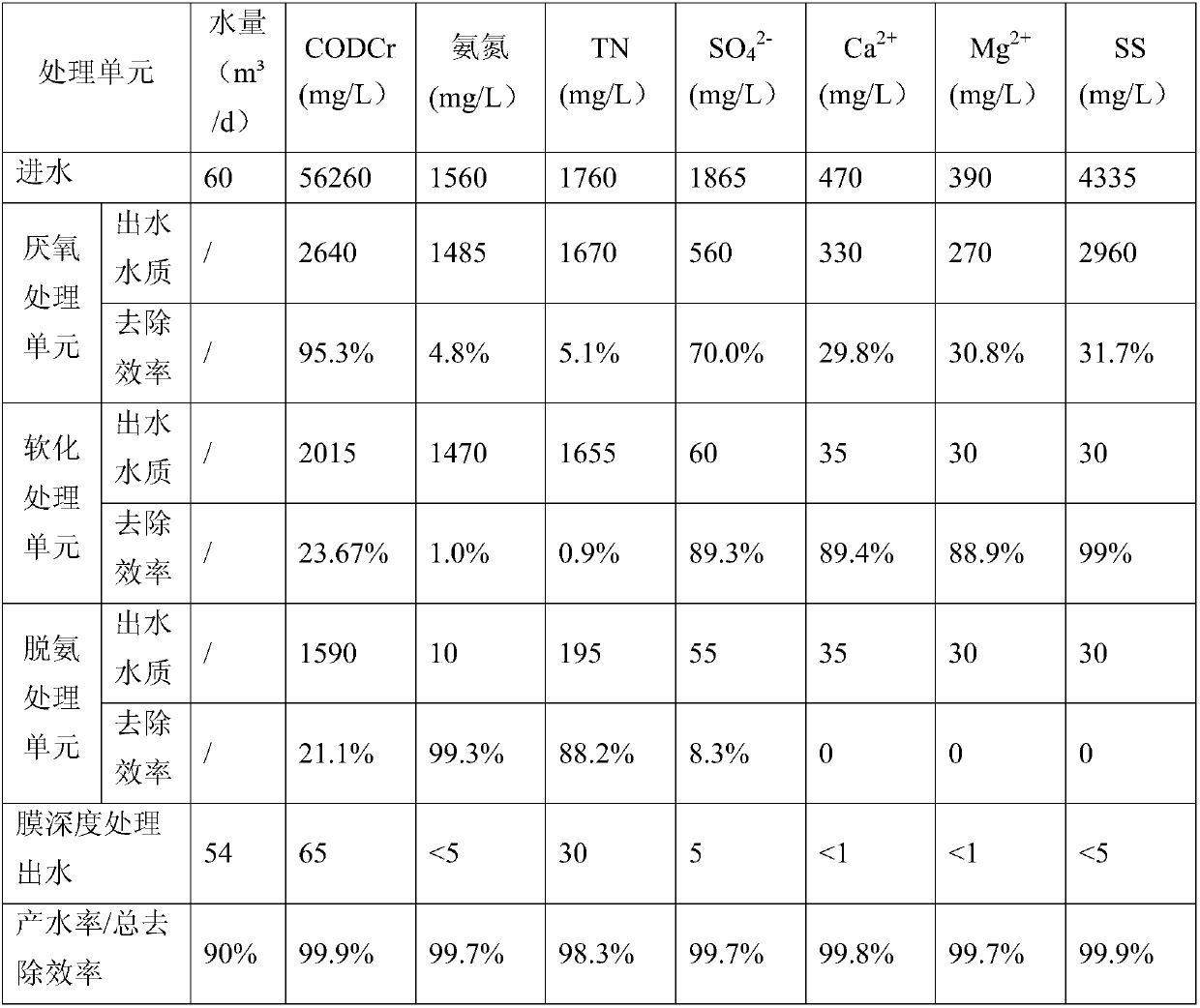

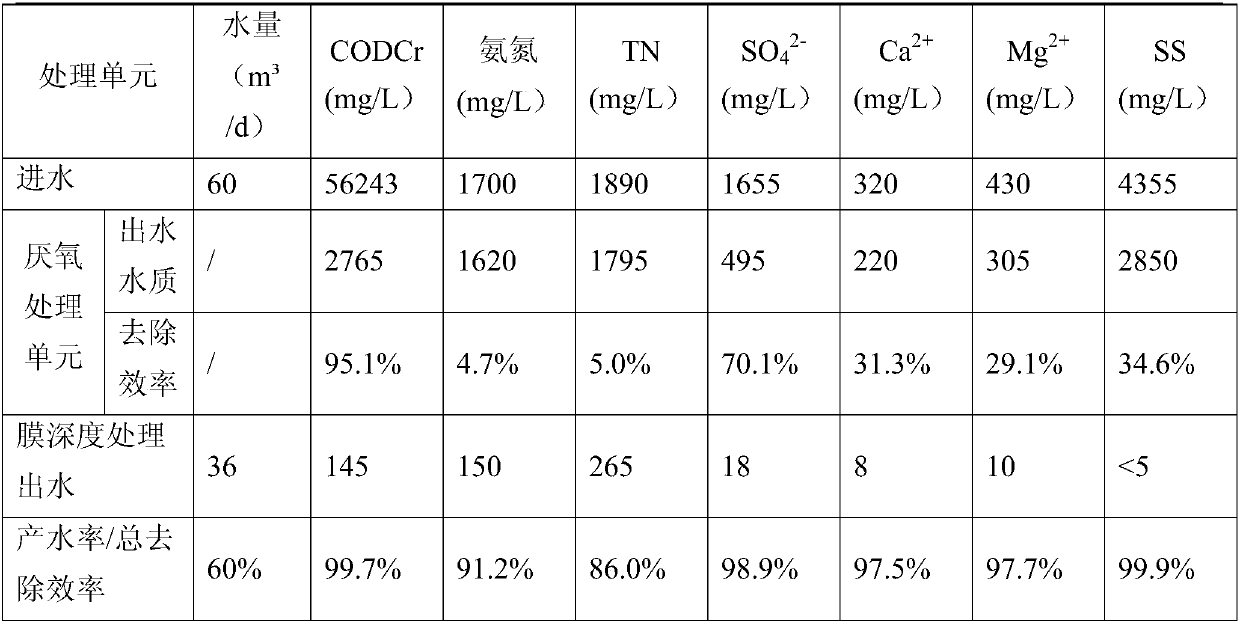

Embodiment 1

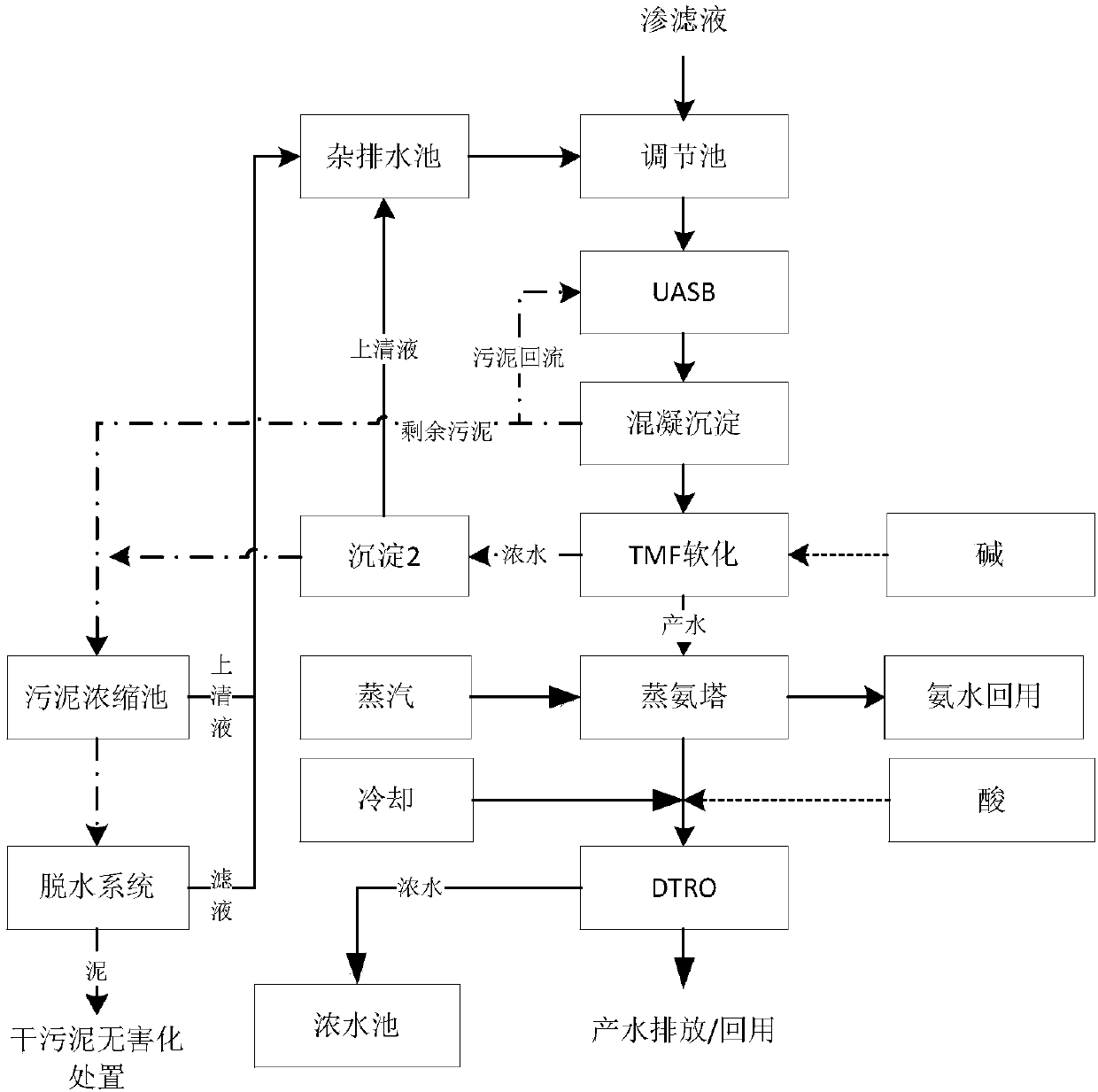

[0032] A treatment method for leachate of a waste incineration plant, the specific steps are as follows:

[0033] (1) Anaerobic treatment: Pump the leachate from the waste incineration plant into the UASB reactor for anaerobic treatment. The residence time of UASB anaerobic treatment is 18 days, the temperature is 35°C±0.5°C, and the ascending flow rate is 2-3m 3 / m 2 h; PAC with an addition amount of 50-200ppm is used as a flocculant for flocculation and sedimentation in the effluent to obtain treatment liquid I and sludge I;

[0034] Part of the sludge reflows into the UASB reactor to stabilize the sludge concentration of UASB, and the remaining sludge is passed into the sludge concentration tank for concentration, and the dry sludge is obtained through the dehydration system, and then harmless treatment is performed.

[0035] (2) Softening treatment: add softening agent to the treatment solution I until the pH value is 10.5-11, control the pH of the treatment solution I to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com