Composite sea water desalination method and system based on cold energy of liquefied natural gas

A technology for liquefied natural gas and seawater, which is applied in chemical instruments and methods, seawater treatment, frozen water/sewage treatment, etc., can solve the problems of slow internal melting speed, fast surface melting speed, opening of salt cell structure, etc., and achieve strong industrial promotion Value, time and energy savings, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

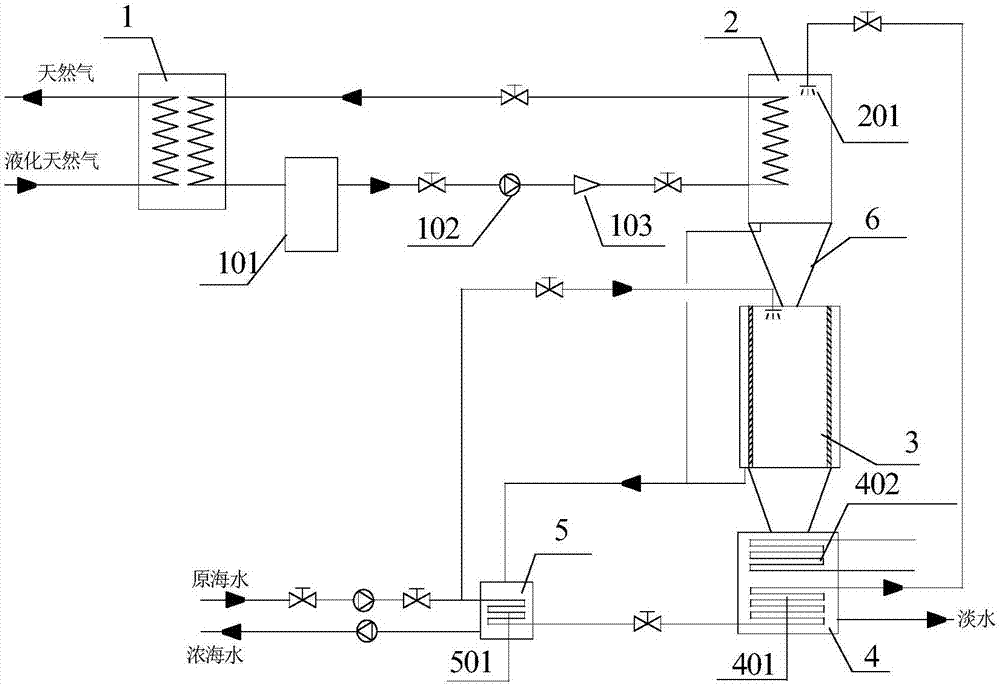

[0040] see figure 1 , a seawater desalination system based on the cold energy of liquefied natural gas, including a secondary refrigerant cooler 1, a seawater flake ice machine 2, and a filter type centrifugal desalination device 3;

[0041] The secondary refrigerant cooler 1 is a plate cooler, and a natural gas channel and a secondary refrigerant channel are arranged in the cooler. The outlet of the secondary refrigerant channel is connected to the seawater flake ice machine 2, and the secondary refrigerant cooler 1 passes through The secondary refrigerant pipeline is connected to the liquid storage tank 101, and a secondary refrigerant pump 102 and a check valve 103 are arranged on the secondary refrigerant pipeline;

[0042] The top of the seawater flake ice machine 2 is provided with a seawater distribution device 201, and the bottom of the seawater flake ice machine 2 is connected with a conical ice-water separator 6; the seawater flake ice machine 2 is connected to a con...

Embodiment 2

[0047] Adopt the system of embodiment 1, present embodiment provides a kind of specific seawater desalination operation, and corresponding process parameter:

[0048] (1) Take seawater with an original salt concentration of 3%, and its temperature is 0.1°C after being pre-cooled by the concentrated seawater recovery tank and the ice-melting tank; indirect heat exchange between liquefied natural gas and absolute ethanol to obtain gaseous natural gas and make it After the temperature of the water ethanol is lowered to -47°C, the obtained absolute ethanol is fully subjected to indirect heat exchange with the sea water, and a part of the sea water is frozen in the flake ice machine, and the thickness of the obtained ice flakes is about 1-3mm; ice water After separation, recover the remaining seawater and keep it on ice for later use;

[0049] (2) Take 501 g of ice obtained in step (1), send it to a filter type centrifugal desalination device, and add raw sea water with a temperatu...

Embodiment 4

[0061] Apply the system of embodiment 1, carry out seawater desalination according to the following steps:

[0062] (1) Take seawater with an original salt concentration of 3%; indirect heat exchange between liquefied natural gas and absolute ethanol to obtain gaseous natural gas and reduce the temperature of absolute ethanol to -47°C, then mix the absolute ethanol with pre-cooling The seawater at 0.1°C fully performs indirect heat exchange, so that part of the seawater freezes; after the ice water is separated, the remaining seawater is recovered and iced for use;

[0063] (2) Take 499g of ice gained in step (1), send it into a filter-type centrifugal desalination device, and add raw seawater with a temperature of 11°C and a quality of 30% of the ice mass;

[0064] (3) Start the filter type centrifugal desalination device, centrifuge the ice-water mixture obtained in step (2) under the condition of 3000r / min for 2min, carry out centrifugation, and separate the ice and water w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com