Garbage leachate processing process and system based on membrane bioreactor-nano filtering membrane technology

A membrane bioreactor and landfill leachate technology, applied in the field of biochemistry, can solve the problems of high cost and complex process, and achieve the effect of high quality and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

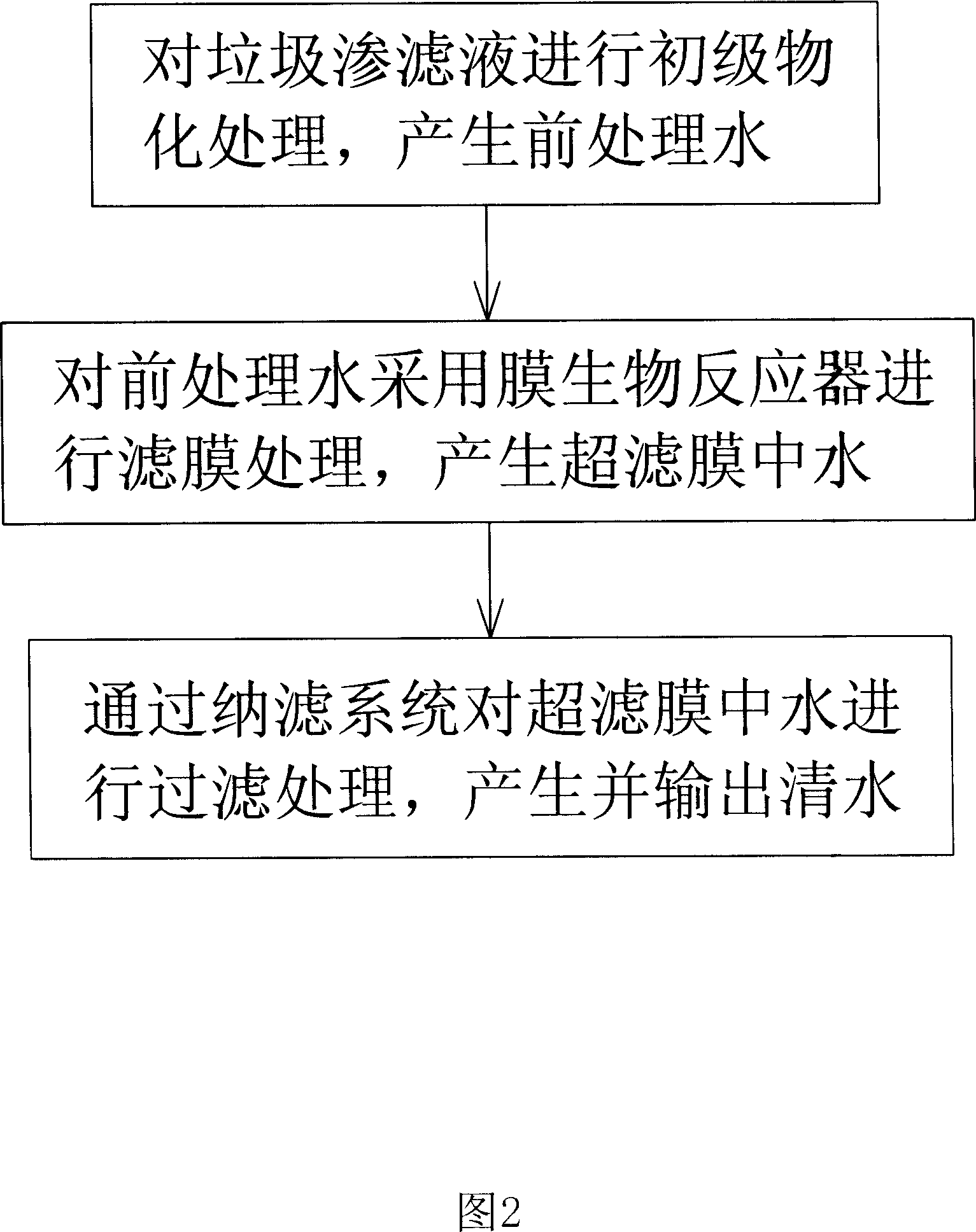

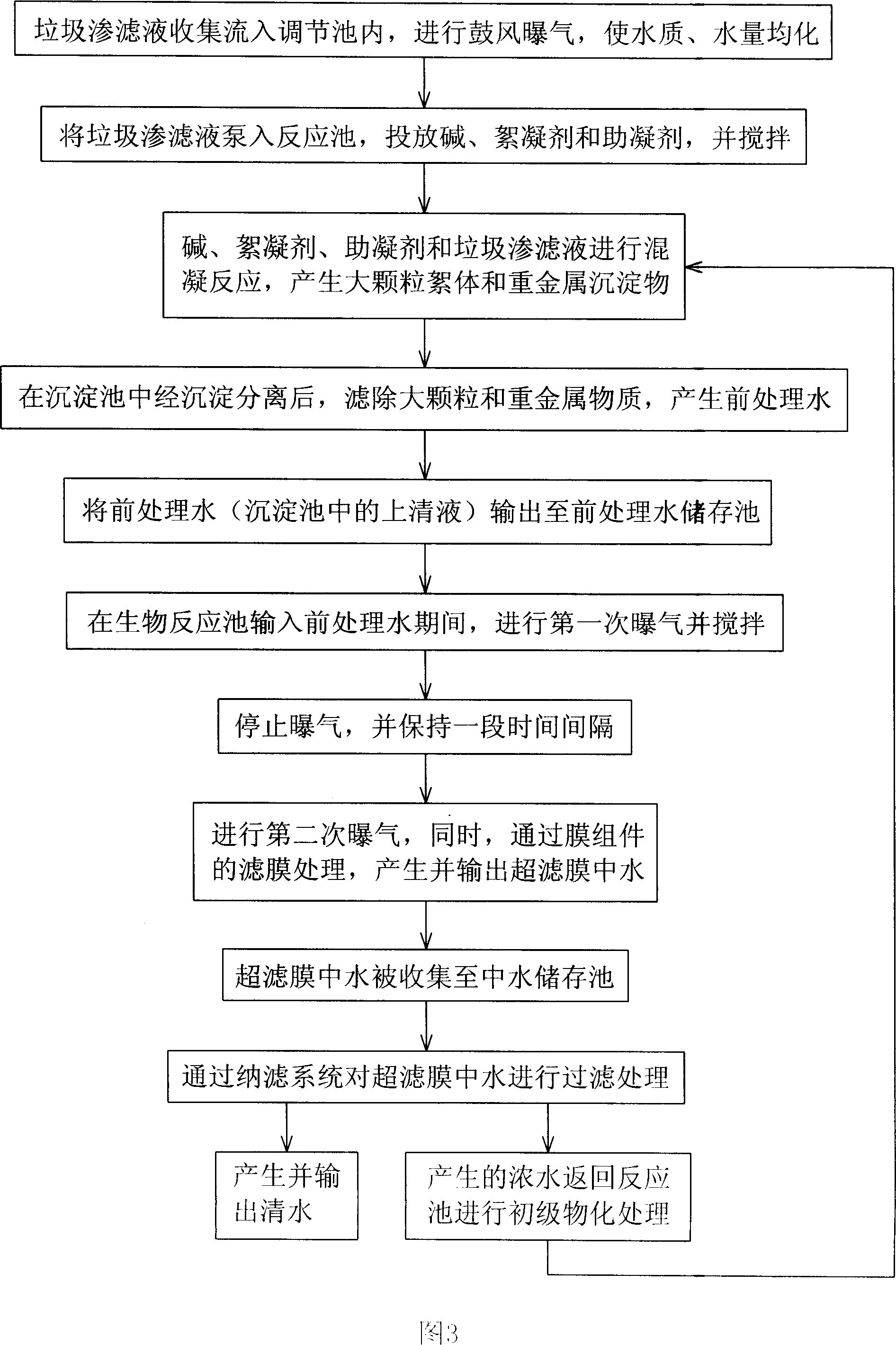

Method used

Image

Examples

Embodiment Construction

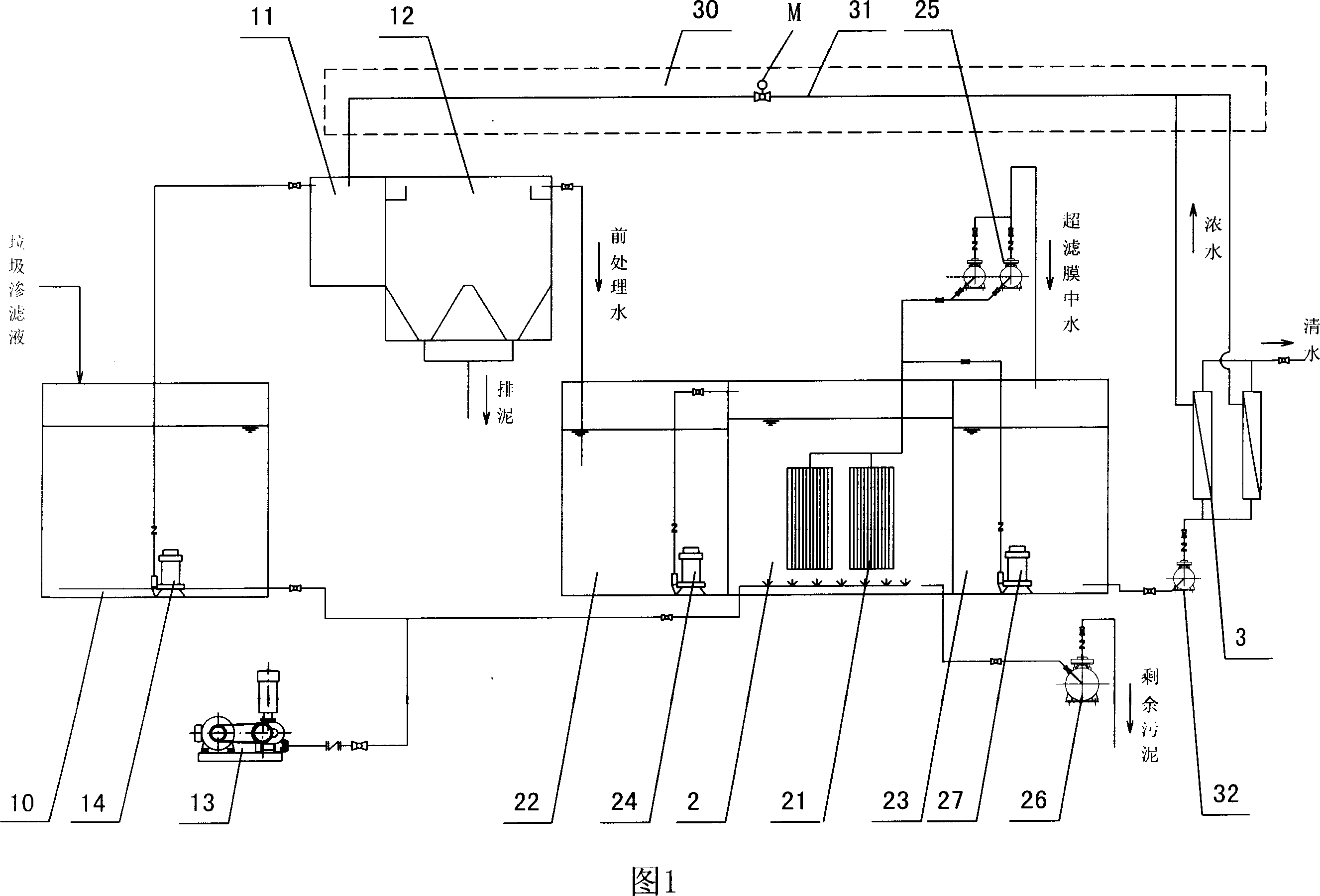

[0037] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0038] According to Fig. 1, the present invention comprises successively the regulating tank 10, reaction tank 11, sedimentation tank 12 and lifting pump 14, air blower 13 that carry out primary physical and chemical treatment to landfill leachate, and bioreaction tank 2 in the membrane bioreactor, pretreatment water Storage tank 22 , reclaimed water storage tank 23 and membrane module 21 , liquid inlet pump 24 , self-priming pump 25 , sludge discharge pump 26 , backwash pump 27 , nanofiltration system 3 and booster pump 32 . The membrane bioreactor is divided into three independent pools, the front pool is the pre-treatment water storage pool 22 , the middle pool is the biological reaction pool 2 , and the rear pool is the reclaimed water storage pool 23 .

[0039]As shown in Figure 1, the pretreatment water produced after the primary physical and chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com