Open channel type photocatalytic ultraviolet-disinfection equipment

A disinfection equipment and photocatalysis technology, which is applied in the direction of light water/sewage treatment, energy wastewater treatment, etc., can solve the problem of incompatibility between the excitation effective interval and the radiation interval, the large heat dissipation energy consumption of electronic ballasts, and the incomplete cleaning of ultraviolet lamps, etc. problems, to achieve the effect of eliminating the impact on the human body, good energy saving effect, and ensuring the quality of effluent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

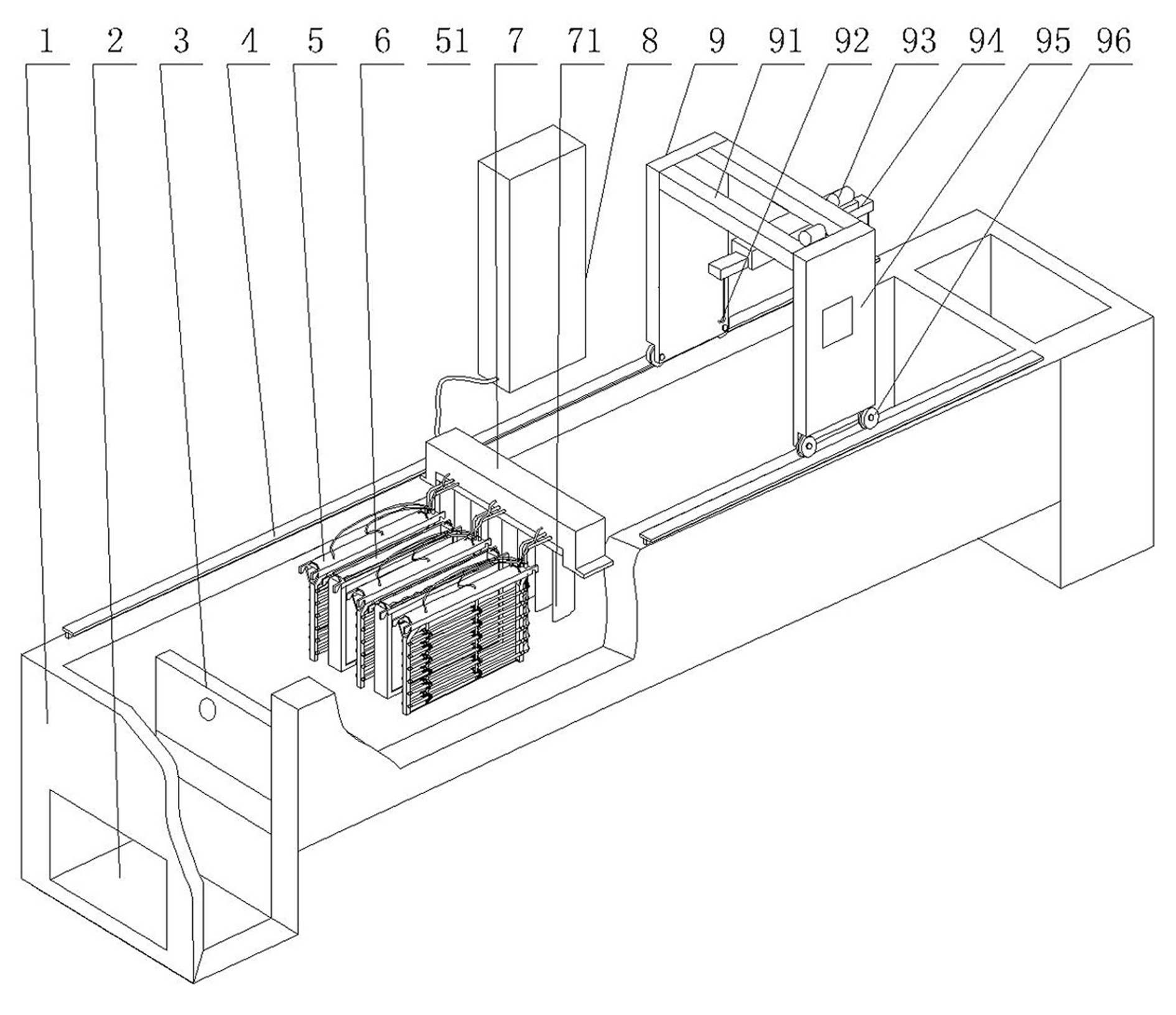

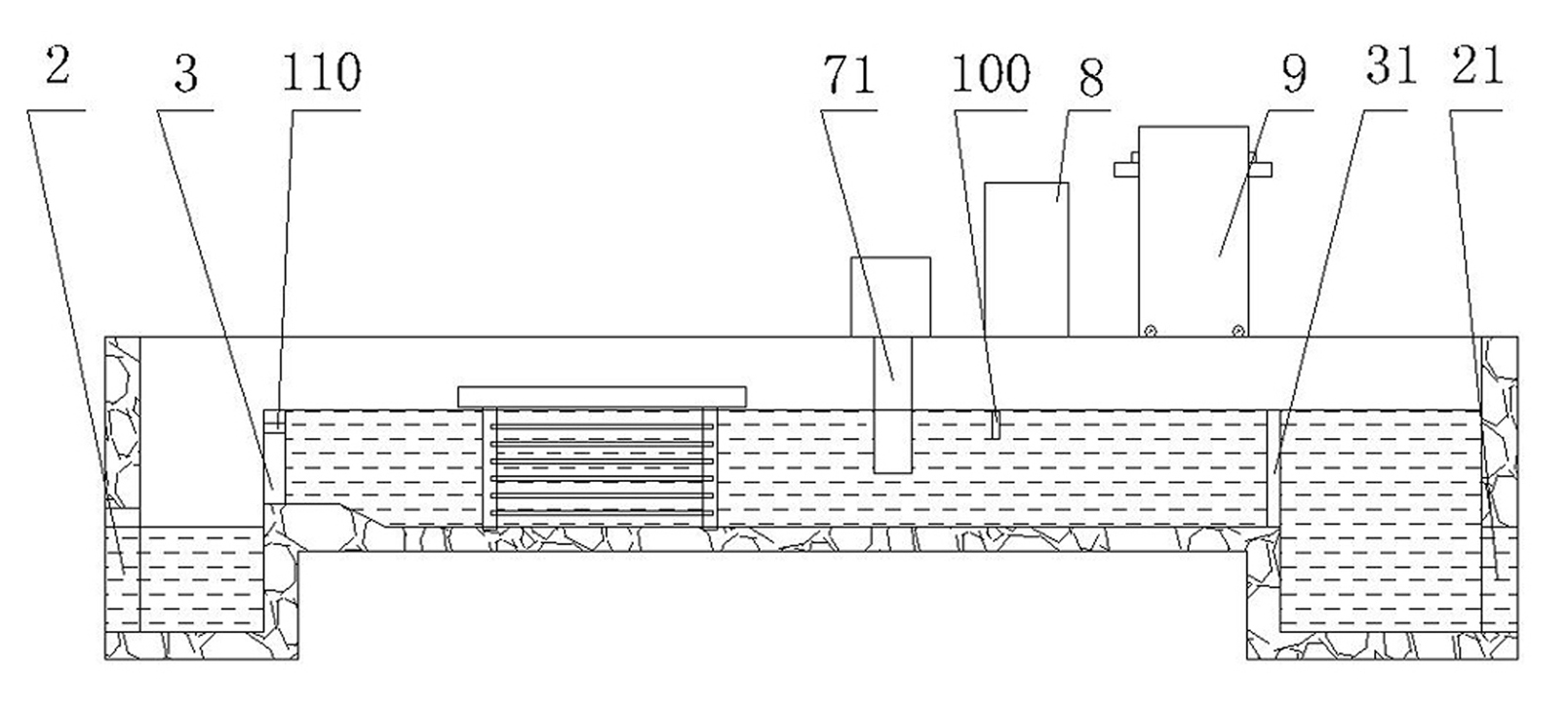

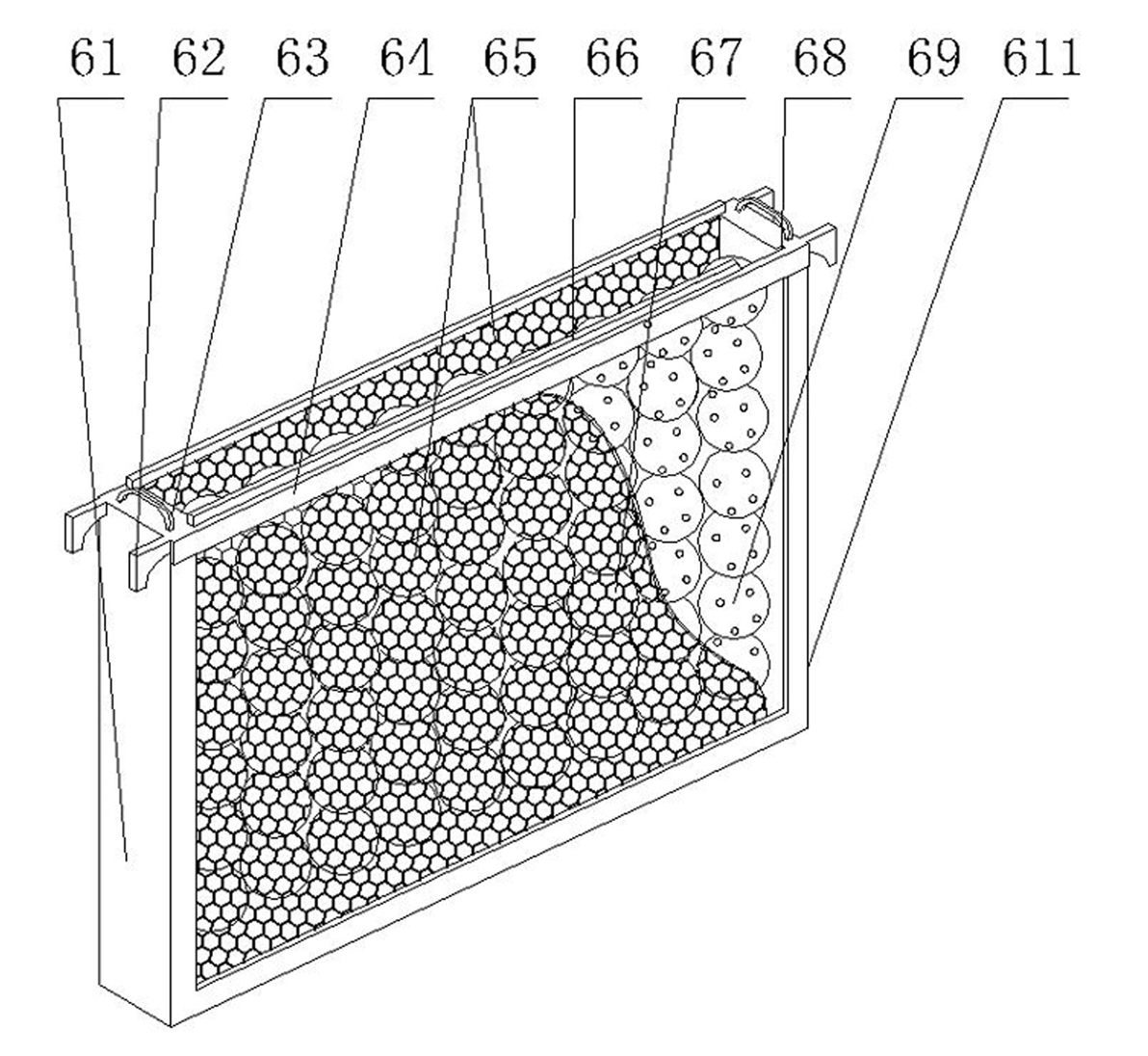

[0042] figure 1 is a structural schematic diagram of the present invention; figure 2 It is a sectional view of the present invention. Depend on figure 1 to combine figure 2 It can be seen that the present invention first designs the open channel body 1 according to the actual water treatment needs. During the civil construction of the open channel 1, 20# I-steel track beams 4 should be pre-embedded on both sides of the open channel 1. The water level control adopts the water weir structure, including the rear water weir door 3, the front water weir door 31, the water inlet hole 21, the water outlet hole 2, etc., the water to be disinfected enters through the water inlet hole 21, and turns over the front water weir door After 31, enter the open channel, and then turn over the weir door 3 and flow out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com