Recycling treating device for flowback pressure liquid in shale gas well fracturing operation

A technology for shale gas wells and treatment devices, applied in water/sewage treatment, mining wastewater treatment, oxidized water/sewage treatment, etc., can solve water resource challenges and other issues, and achieve the effect of zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

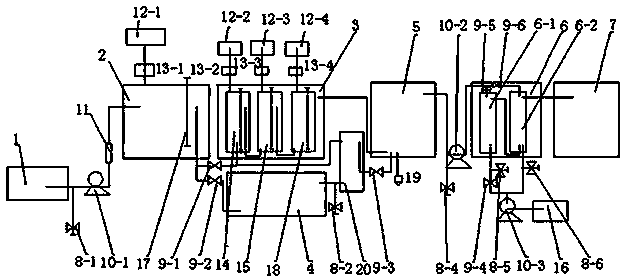

[0028] Such as figure 1As shown in the figure, a reuse treatment device for flowback pressure fluid in the fracturing operation of shale gas wells, including a wastewater tank 1, a regulating tank 2, a composite coagulation reaction device 3, a settling tank 5, a solid The liquid separation device 6 and the clear water tank 7, the composite coagulation reaction device 3 include a fast stirring tank 14, a slow stirring tank 15 and an oxidation tank 18 connected successively by pipelines, and the upper end of the regulating tank 2 passes through the first constant flow pump 13-1 and The regulator dosing device 12-1 is connected, the fast stirring tank 14 is connected with the flocculant dosing device 12-2 through the second constant flow pump 13-2, and the slow stirring tank 15 is connected with the assistant through the third constant flow pump 13-3. The coagulant dosing device 12-3 is connected, the oxidation tank 18 is connected with the oxidant dosing device 12-4 through the...

Embodiment 2

[0031] This embodiment is further limited on the basis of Example 1, the regulating pool 2 is connected to the fast stirring pool 14 through the first valve 9-1, and the regulating pool 2 is connected to the electroflocculation reaction device 4, The filter tank 20 is connected, and the filter tank 20 is connected with the fast stirring tank 14 and the settling tank 5 respectively, and a third valve 9-3 is provided between the filter tank 20 and the settling tank 5, and the suspended solids, The content of COD, heavy metal ions, etc. can be processed through electrocoagulation reaction, filtered, and then enter the composite coagulation reaction device 3, which can effectively reduce the content of suspended solids, COD, heavy metal ions, etc. in the flowback pressure liquid. Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0033] This embodiment is further defined on the basis of the above embodiments, a first sampling port 8 - 1 , a first lift pump 10 - 1 and a flow meter 11 are sequentially provided between the waste water tank 1 and the regulating tank 2 . Through the setting of the first sampling port 8-1, it is mainly to sample the flowback pressure liquid in the waste water tank, and analyze its composition to determine the subsequent treatment process; through the setting of the first lift pump 10-1, Mainly through the first lifting pump 10-1, the flowback pressure liquid in the waste water pool is transported to the regulating tank 2 for processing, and the flow meter 11 can be set according to the processing capacity of the device in the flowback pressure liquid treatment process, within a unit time For the processing capacity of flowback pressure liquid; the second lift pump 10-2 and the fourth sampling port 8-4 are arranged between the settling tank 5 and the solid-liquid separation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com