Method for processing city household garbage leachate

A technology for landfill leachate and biochemical treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. cost and other issues, to achieve the effect of high degree of industrialization, reduction of secondary pollution, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

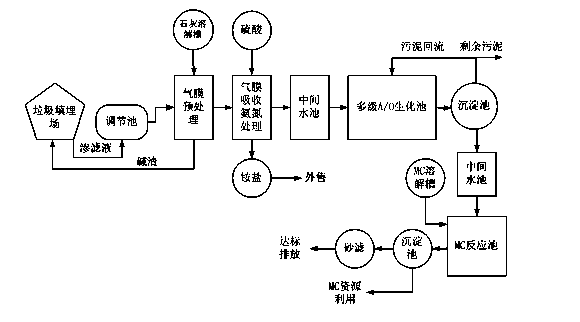

[0031] Such as figure 1 Shown: a landfill leachate treatment method, referred to as GBA (Gas membrane + Biology + Adsorption Treatment) in English.

[0032] Firstly, the landfill leachate is collected, and the collected landfill leachate is adjusted by lime to adjust the pH value of the landfill leachate, gas membrane acid absorption system, high-efficiency AO biochemical treatment system, and modified carbon deep adsorption system, so as to meet the national emission standards.

[0033] The main purpose of the gas film acid absorption system is to remove the high concentration of ammonia nitrogen in the landfill leachate to eliminate the impact of ammonia nitrogen on the biochemical treatment of the landfill leachate. At the same time, the gas film acid absorption system can effectively remove heavy metal pollutants in the landfill leachate, and can also remove part of COD , total phosphorus;

[0034] The gas film adsorption ammonia nitrogen technology has a good effect of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com